Device for measuring optical free-form surface

A free-form and curved-surface technology, which is used in measurement devices, optical devices, optical instrument testing, etc., can solve problems such as expensive equipment, difficulty in measuring optical free-form surfaces, and restrictions on the application of optical free-form surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

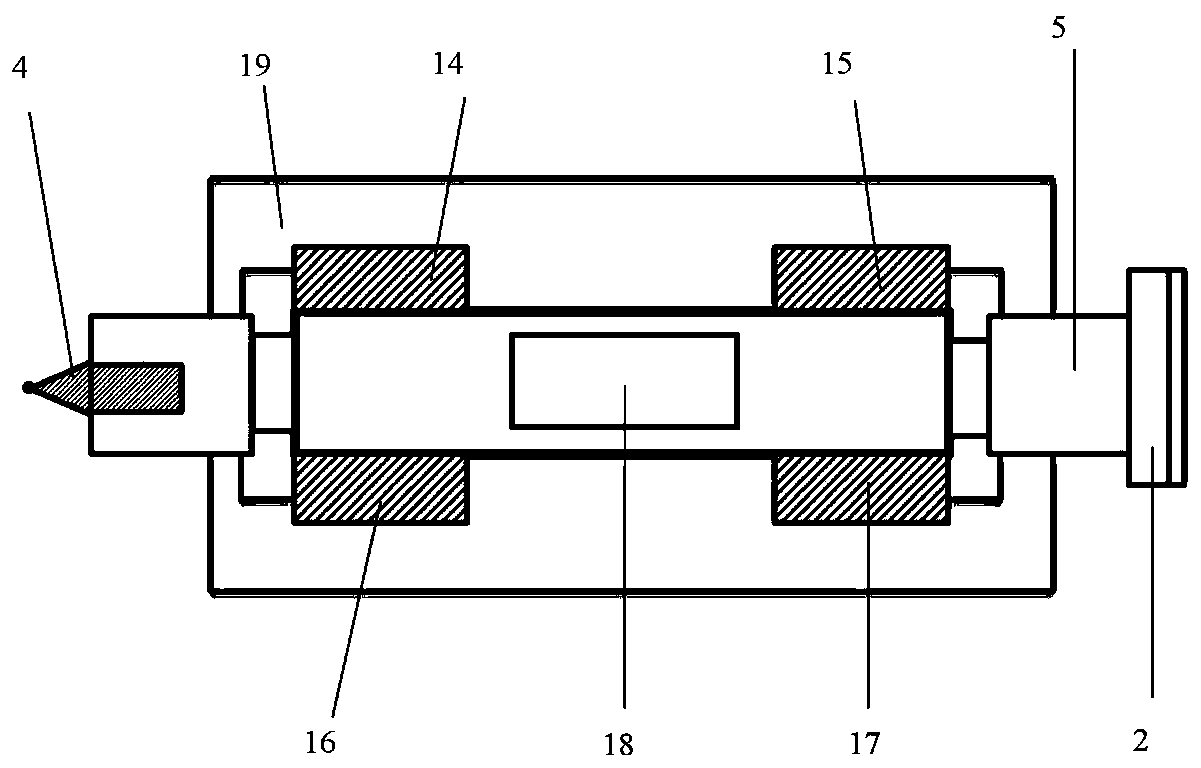

[0008] The invention consists of a high-precision air-floating probe (including a probe, a probe shaft and a shaft sleeve), a focusing laser displacement sensor and its signal acquisition circuit, a nano two-dimensional displacement mechanism and its controller.

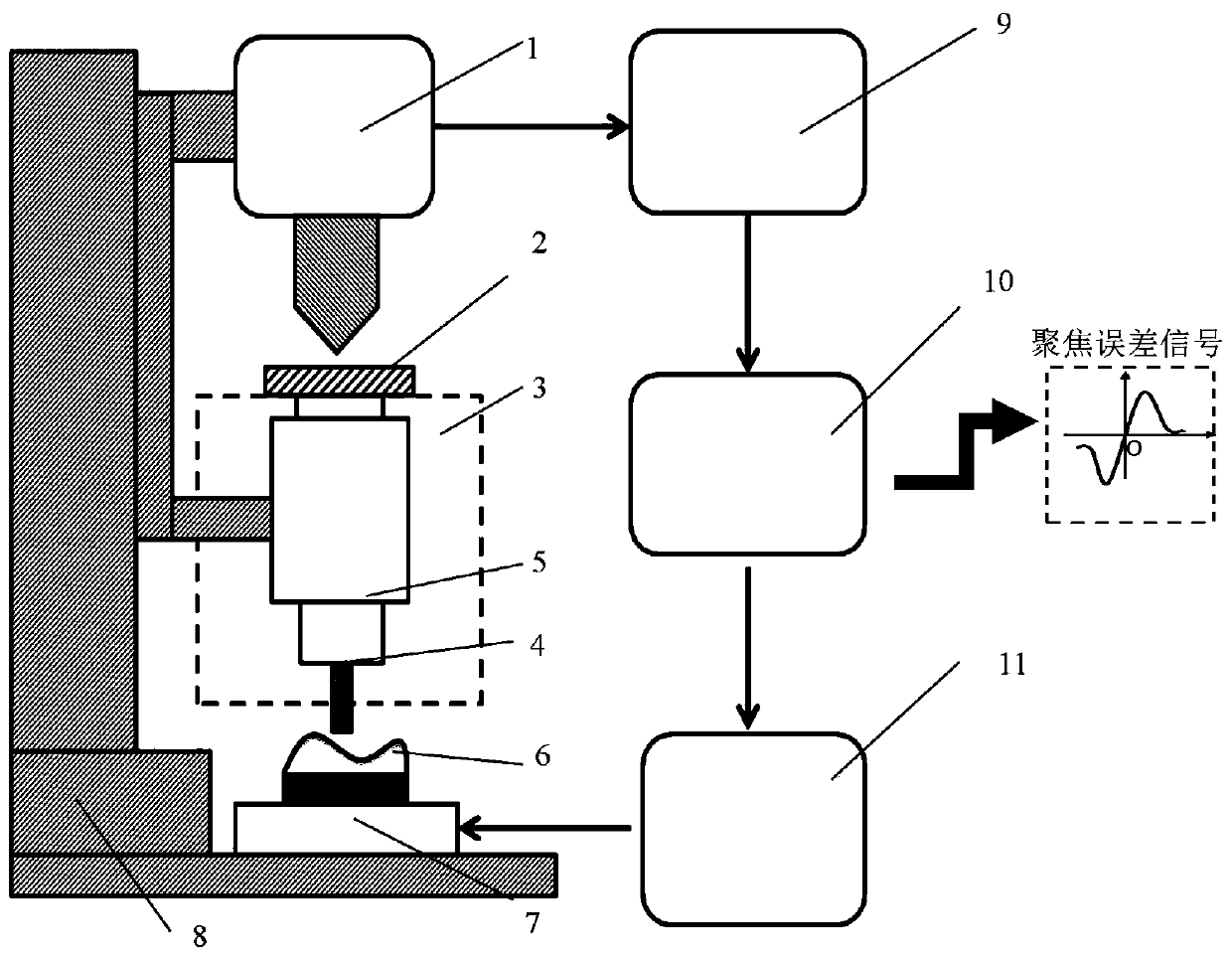

[0009] The schematic diagram of the principle of the large-slope optical free-form high-precision measurement system is as figure 1 , Including focused laser displacement sensor 1, reflector 2, high-precision air-floating probe 3 (including probe 4 and probe axis 5), test workpiece 6, nano two-dimensional displacement mechanism 7, marble platform 8, focused laser The signal acquisition circuit 9 of the displacement sensor, the industrial computer 10, and the controller 11 of the nano two-dimensional displacement mechanism are composed. The industrial computer 10 controls the nano two-dimensional displacement mechanism 7 to move according to the designed path through the nano two-dimensional displacement mechanism control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com