A Construction Method of Concrete Vibration for Tunnel Vault

A construction method and concrete technology, which is applied in the direction of earthwork drilling, tunnel, tunnel lining, etc., can solve the problems that the construction effect cannot be guaranteed, and it is not suitable for the concrete vibration construction of the vault, so as to achieve convenient operation, high quality and less time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

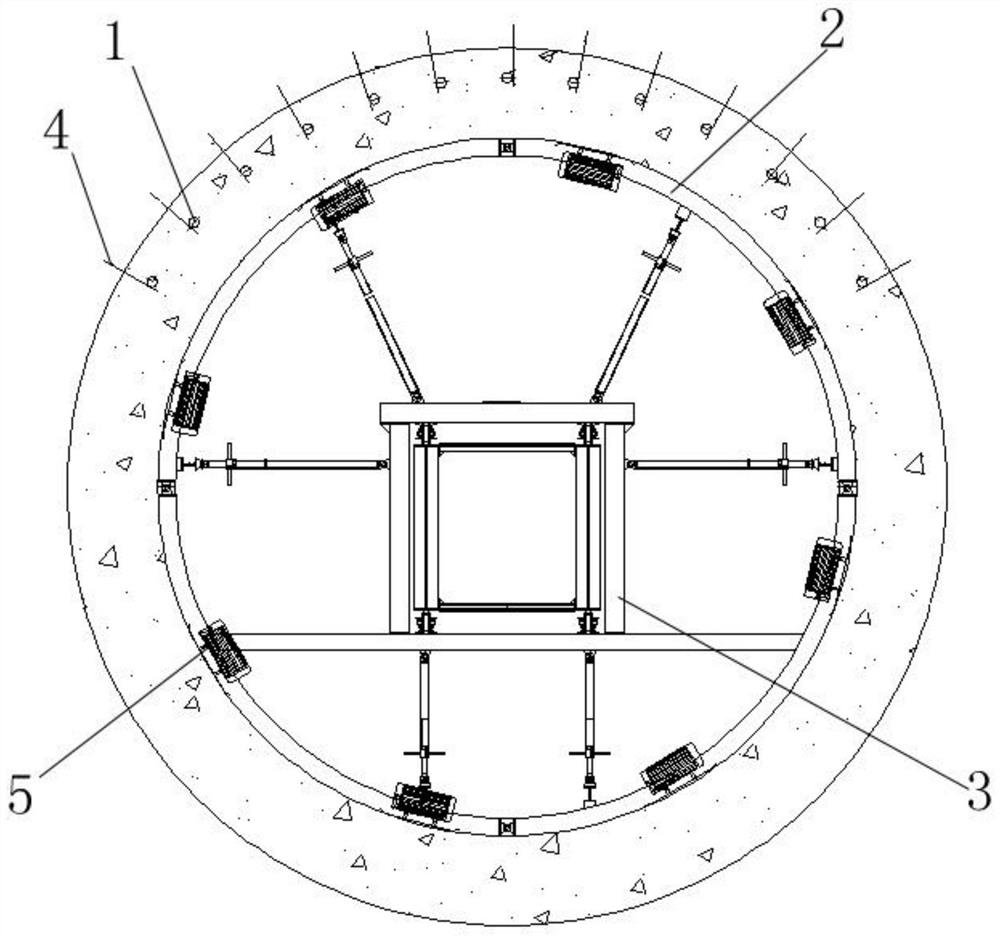

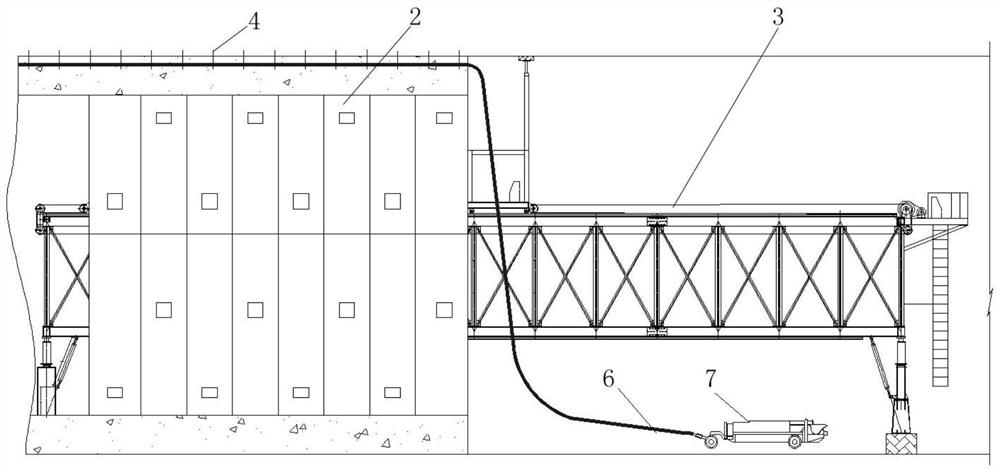

[0042] The construction method of the tunnel vault concrete vibration specifically comprises the following steps:

[0043] Step 1, Measure the scribe line:

[0044] Use the leveling and setting-out instrument equipment to draw a line in the center of the vault along the axis of the tunnel, and draw two side lines at 60° on both sides of the line, and use the position between the two side lines as the construction scope of the vault.

[0045] In this embodiment, red paint is sprayed from a spray gun for scribing.

[0046] Step 2, preset bellow 1:

[0047] Within the construction scope of the vault, one Φ80mm corrugated pipe 1 is arranged every 60cm along the tunnel ring direction. The distance between the center of the corrugated pipe 1 and the lining formwork 2 is 50cm. Each corrugated pipe 1 runs through the entire 12m-long warehouse along the tunnel axis direction. , where, every 60cm along the ring direction of the tunnel refers to the data measured by the tape measure ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com