Iron roughneck floating type tong head hanging device and debugging method thereof

A suspension device, iron drill technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problem that the iron drill tong head assembly cannot float, etc., to improve the drill pipe handling capacity, reduce damage, improve the adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

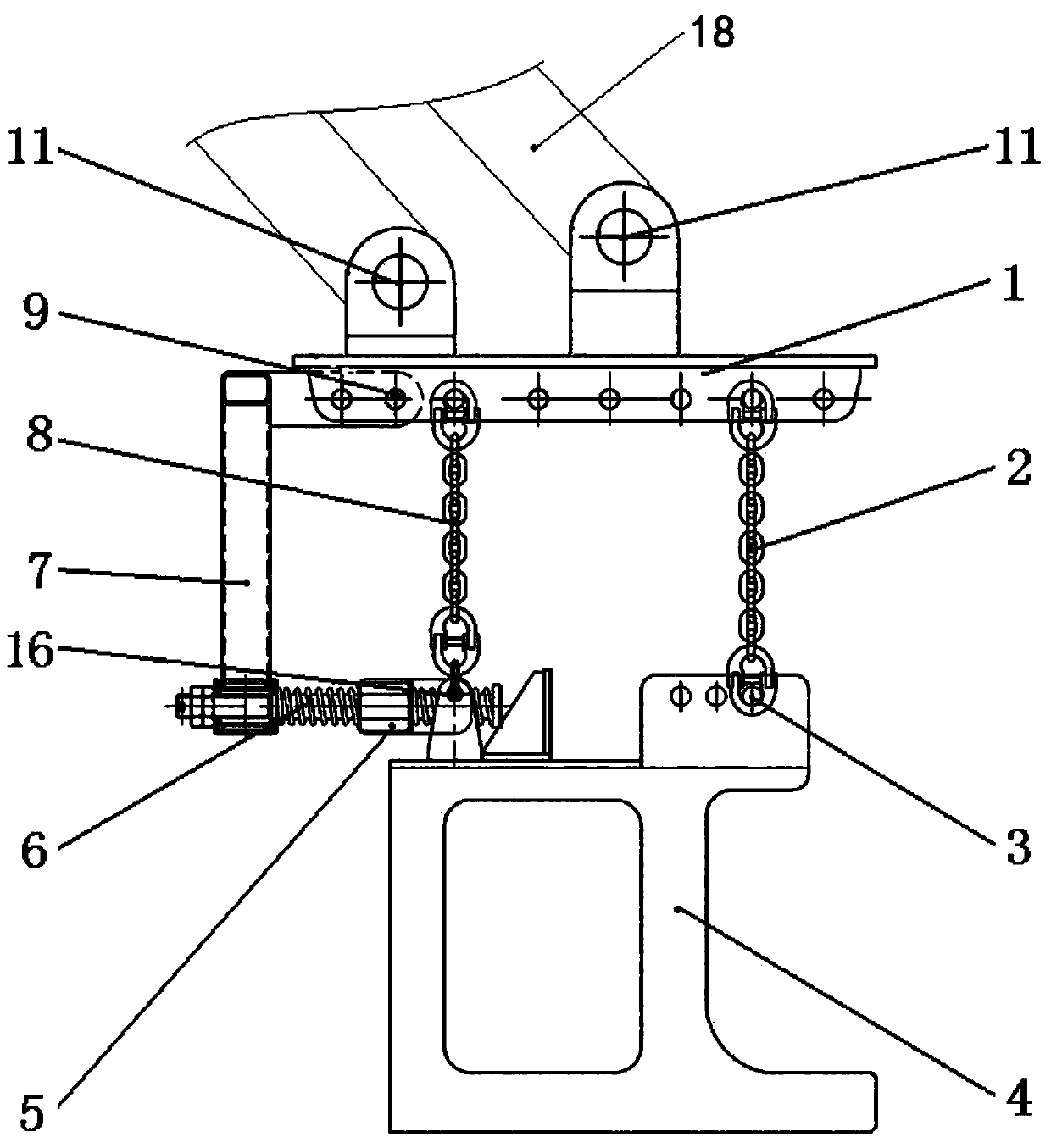

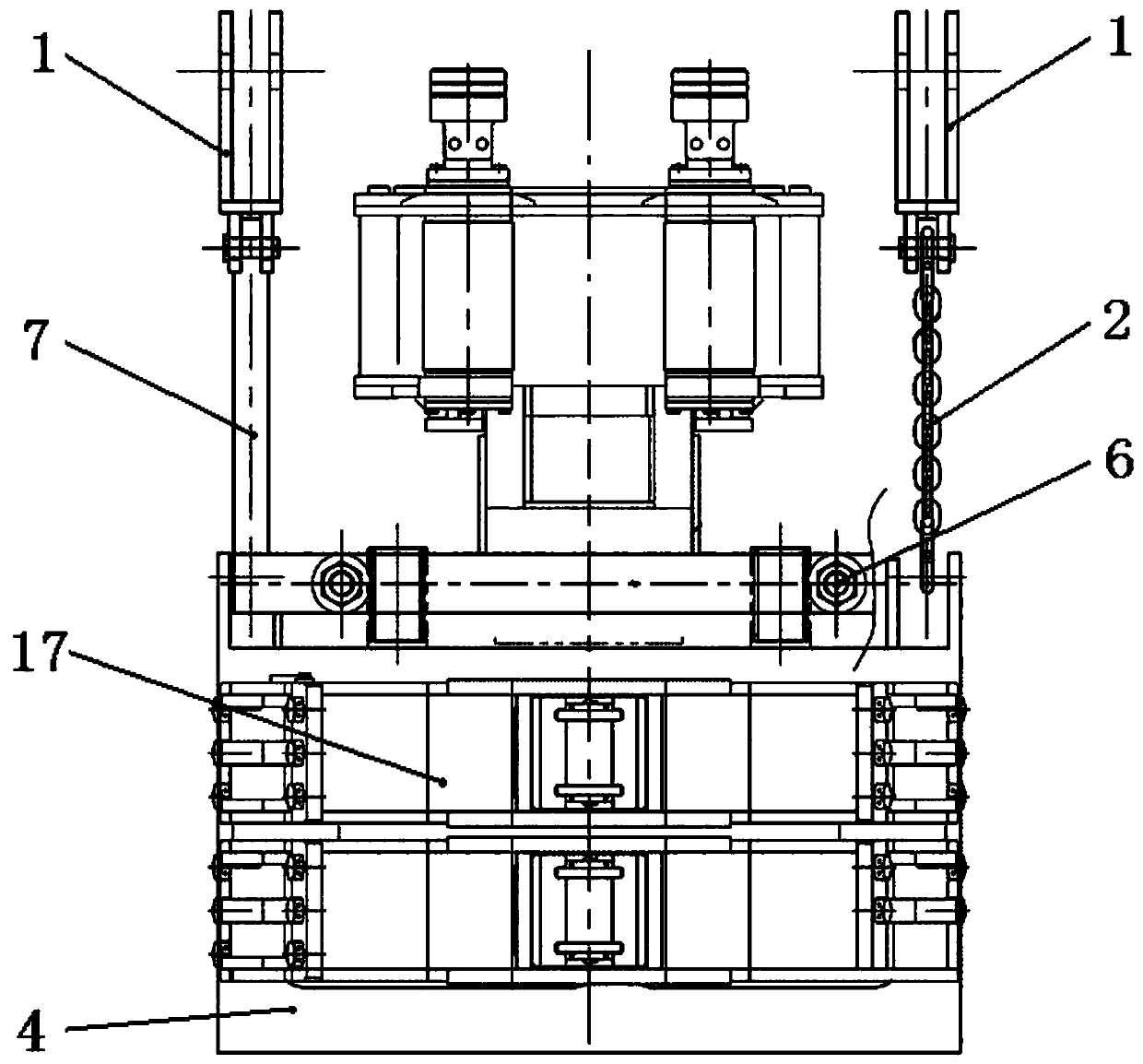

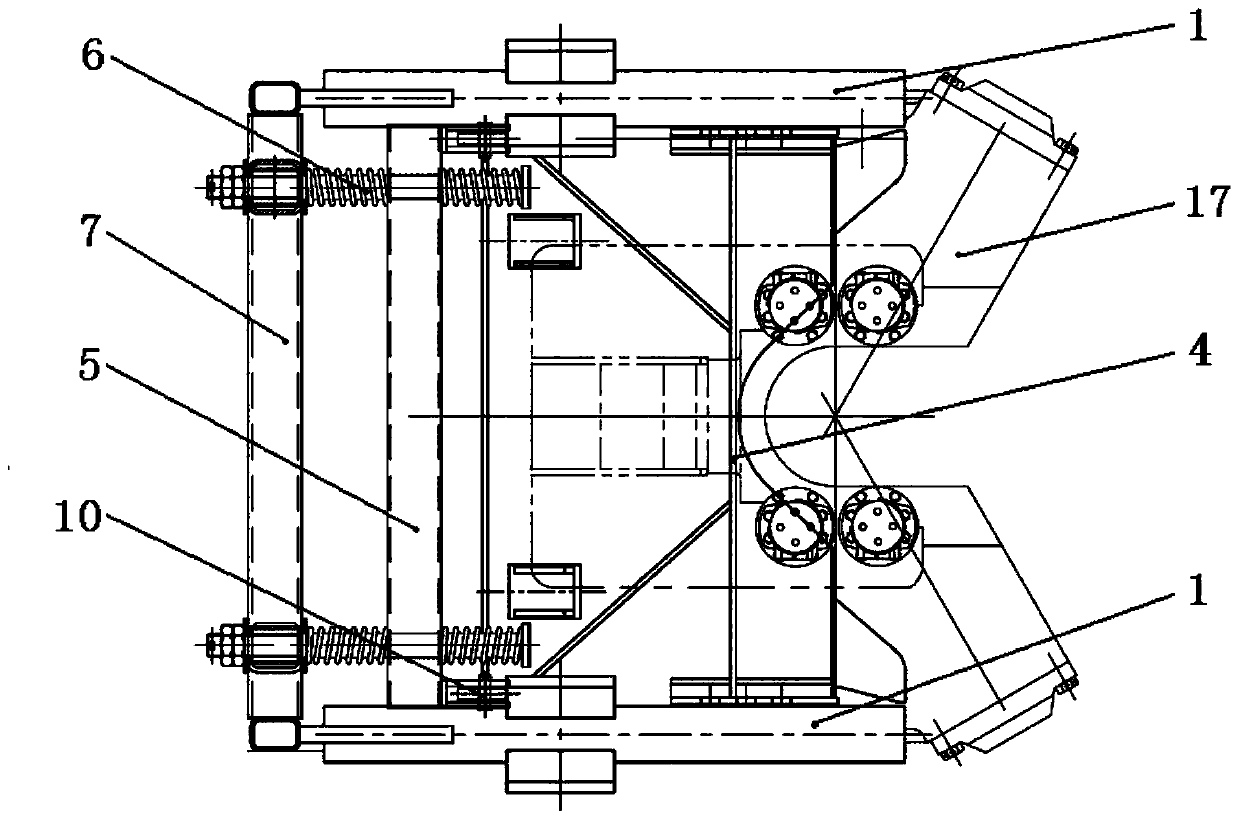

[0031] The present invention is an iron driller's floating clamp head suspension device, such as Figures 1 to 4 As shown, it includes a connecting frame 4 affixed to the pincer head assembly 17. The pincer head assembly 17 includes a punching pliers and a twisting pliers. 4 and the hanging beam 1 are provided with a number of parallel flexible suspension devices and a number of parallel buffer devices 6; The connecting frame 4 is rotationally connected; each of the buffer devices 6 includes a guide pin 12 arranged parallel to the suspension beam 1, and a plurality of buffer springs 13 are set on the guide pin 12, and the connecting end of the guide pin 12 is threaded. Connect the nut 15 used to adjust the compression force of the buffer spring 13; the cross brace 5 is radially and vertically passed through the middle of some buffer springs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com