Emulsified asphalt with solid content higher than 70% and preparation method thereof

A technology of emulsified asphalt and solid content, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor asphalt performance, long time for demulsification, poor performance, etc., and achieve good quality and overcome slow demulsification speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

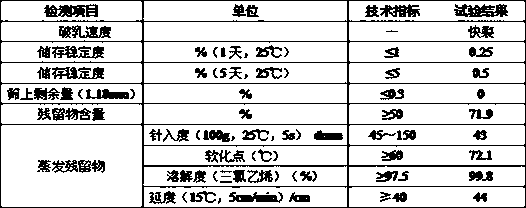

Embodiment 1

[0018] Take the production of 500g high-solid content emulsified asphalt as an example, its raw material composition is:

[0019] No. 50 bitumen 370g distilled water: 120g compound modified by SBS and SBR

[0020] Emulsifying agent: 7.5g, described emulsifying agent is the mixture of lauryl ammonium chloride and cetyltrimethylammonium bromide, and its proportioning is 7.5:2.5, waterproof preservation, shake up before use.

[0021] Stabilizer: 2.5g, described stabilizer is cellulose, waterproof and sealed preservation, dissolves in water during use.

[0022] Its preparation method is as follows:

[0023] (1) Take No. 50 asphalt and heat it to 160°C to 180°C, then add linear SBS modifier and SBR modifier. Cut on the cutting machine, first cut at a speed of 2500r / min for 5 minutes, and then cut at a speed of 4000r / min for 80 minutes to obtain SBR and SBS composite modified asphalt:

[0024] (2) Pour the emulsifier into the steamed pomegranate water at 25°C, stir evenly, add an...

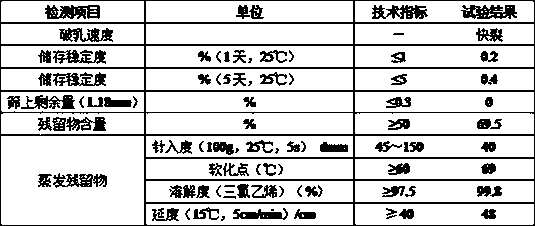

Embodiment 2

[0030] Take the production of 500g high-solid content emulsified asphalt as an example, its raw material composition is:

[0031] No. 50 bitumen modified by SBS: 368g

[0032] Water: 119.5g

[0033] Emulsifying agent: 10g, described emulsifying agent is the mixture of lauryl ammonium chloride and cetyl trimethyl ammonium bromide

[0034] Mixture, its ratio is 7:3, waterproof storage, shake well before use.

[0035] Stabilizer: 2.5g, described stabilizer is cellulose, waterproof and sealed preservation, dissolves in water during use.

[0036] Its preparation method is as follows:

[0037] (1) Take No. 50 asphalt and heat it to 160°C to 180°C, then add linear SBS modifier and SBR modifier. Cut on the cutting machine, first cut at a speed of 2000r / min for 10 minutes, and then cut at a speed of 4000r / min for 80 minutes to obtain SBR and SBS composite modified asphalt:

[0038] (2) Pour the emulsifier into the steamed pomegranate water at 55°C, stir evenly, add an appropriate ...

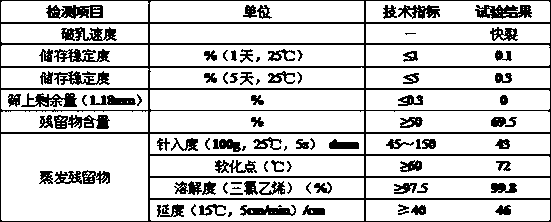

Embodiment 3

[0044] Take the production of 500g high-solid content emulsified asphalt as an example, its raw material composition is:

[0045] No. 50 bitumen modified by SBS: 365g

[0046] Water: 110g

[0047] Emulsifying agent: 7.5g, described emulsifying agent is the mixture of lauryl ammonium chloride and cetyltrimethylammonium bromide, and its proportioning is 7.5:2.5, waterproof preservation, shake up before use.

[0048] Stabilizer: 2g, described stabilizer is cellulose, and waterproof seal preserves, and dissolves in water during use.

[0049] Propolis: 15.5g

[0050] Its preparation method is as follows:

[0051] (1) Take No. 50 asphalt and heat it to 160°C to 180°C, then add linear SBS modifier and SBR modifier. Cut on the cutting machine, first cut at a speed of 2500r / min for 10 minutes, and then cut at a speed of 4000r / min for 75 minutes to obtain SBR and SBS composite modified asphalt:

[0052] (2) Pour the emulsifier into the steamed pomegranate water at 20°C, stir evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com