Chitosan/ poly-sulfonic acid group betaine dual network self-healing hydrogel and preparation method thereof

A technology of polysulfonic acid group and sulfonic acid beet, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of high self-healing performance and inability to obtain mechanical properties at the same time, and achieve the effect of mechanical property recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

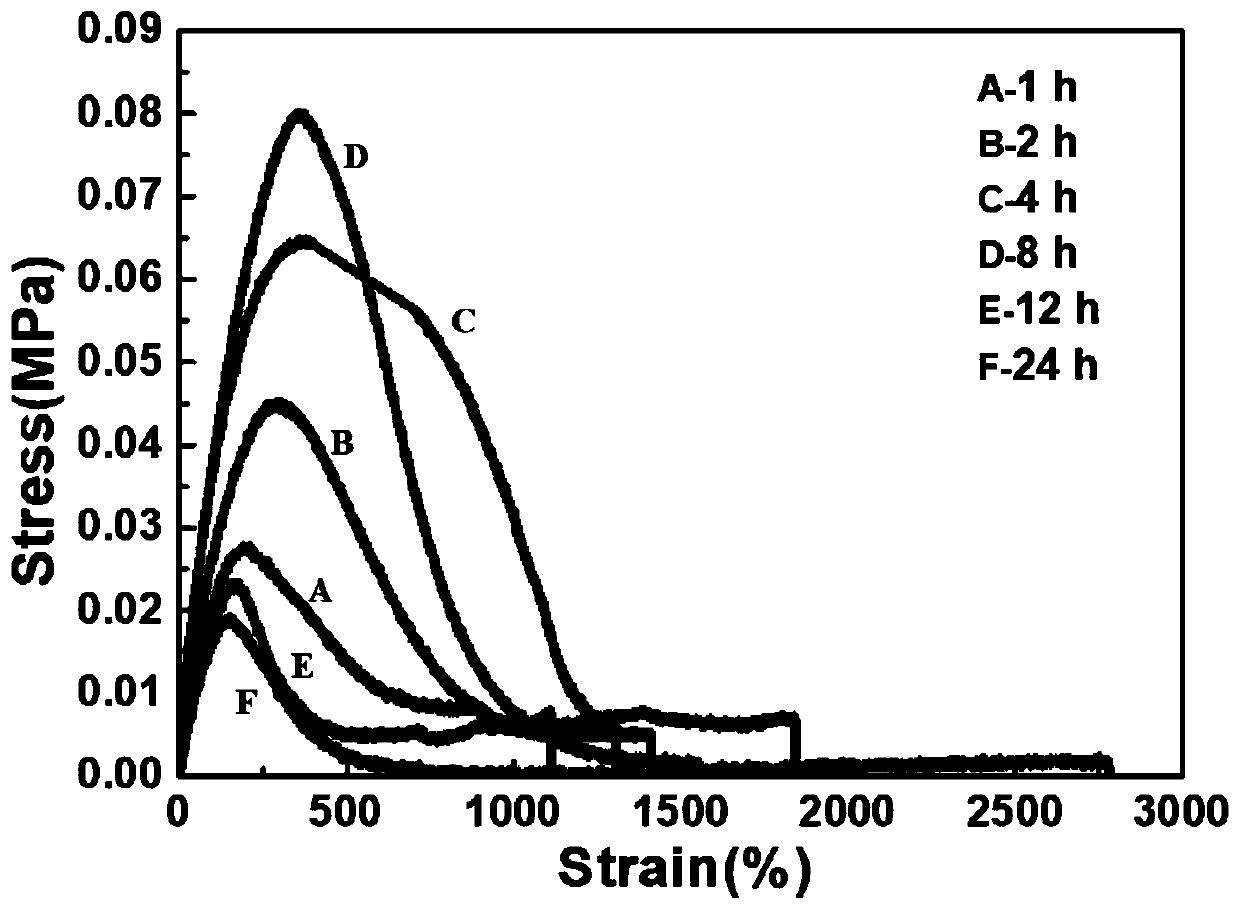

Examples

Embodiment 1-7

[0039] A preparation method of chitosan / polysulfobetaine double network self-healing hydrogel, comprising the following preparation steps:

[0040] 1) Prepare chitosan (molecular weight less than 10000Da), sulfobetaine methyl methacrylate, cetyltrimethylammonium chloride, octadecyl methacrylate and initiator α-ketoglutaric acid mixed solution;

[0041] 2) Deoxygenate the mixed solution, and ultrasonically remove the air bubbles in the mixed solution to obtain a prepolymerized solution;

[0042] 3) Inject the pre-polymerization liquid into the light-transmitting mold, irradiate the reaction with ultraviolet light, and obtain the pre-gel after the reaction is completed;

[0043] 4) soaking the pregel in the multivalent anion solution to obtain the chitosan / polysulfobetaine double network self-healing hydrogel.

[0044] Wherein, the deacetylation degree of chitosan described in embodiment 1-5 is 95%, feeds nitrogen gas during deoxygenation, and multivalent anion solution is sat...

Embodiment 2

[0060] The strain-resistance change rate curve of the double network hydrogel prepared in Example 2 is as follows Figure 6 As shown in the figure, it can be known that the resistance change rate of the double network hydrogel is greater than 80% under 50% strain, and the resistance change rate reaches 30% under 25% strain.

[0061] The resistance change rate curves of the double-network hydrogel prepared in Example 2 under different bending angles of the simulated joints are shown in Figure 7. It can be seen from the figure that as the joint bending angle increases, the resistance change rate increases significantly , when the bending angle is 90°, the resistance change rate is about 40%, and when the bending angle is 135°, the resistance change rate is greater than 50%.

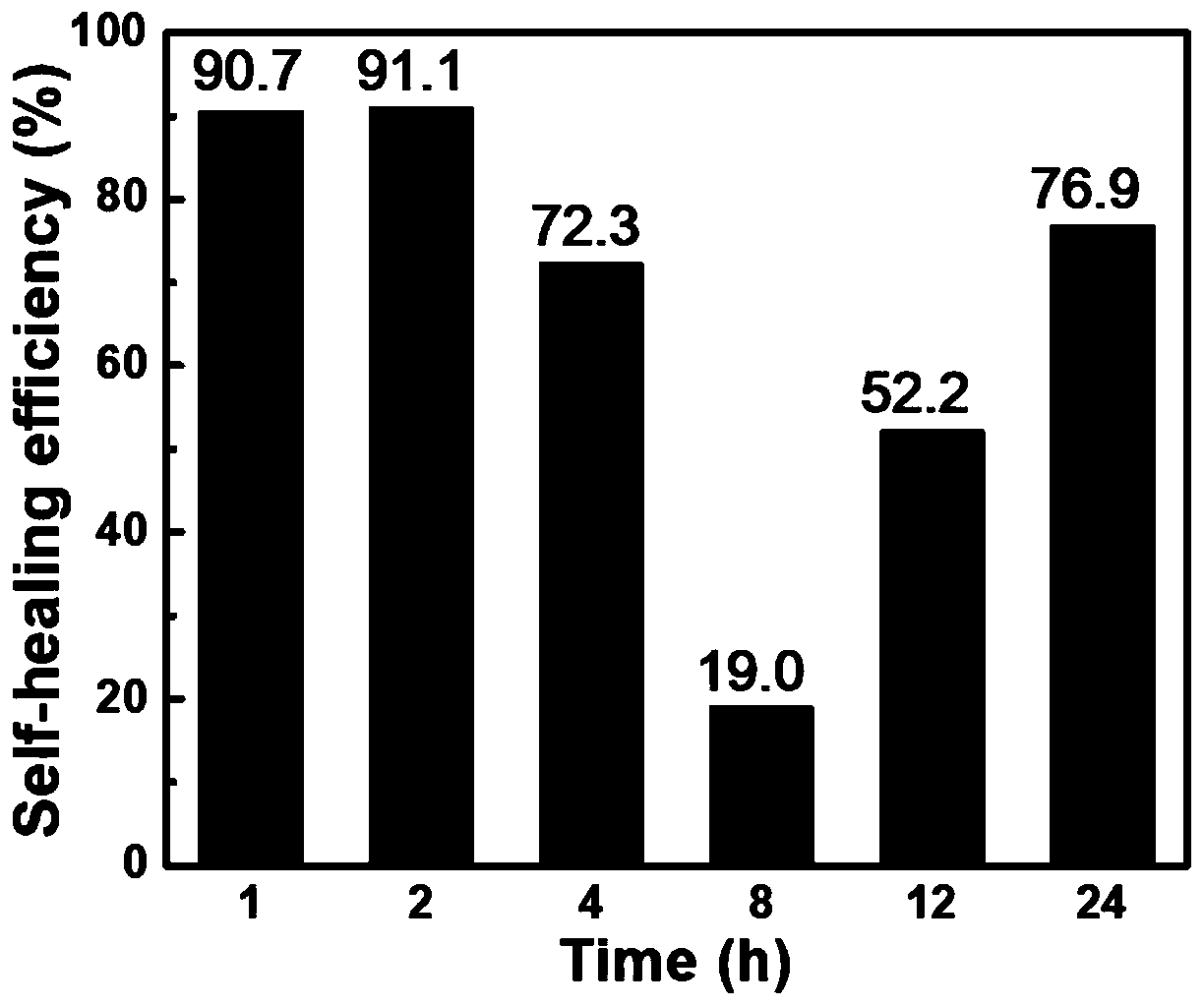

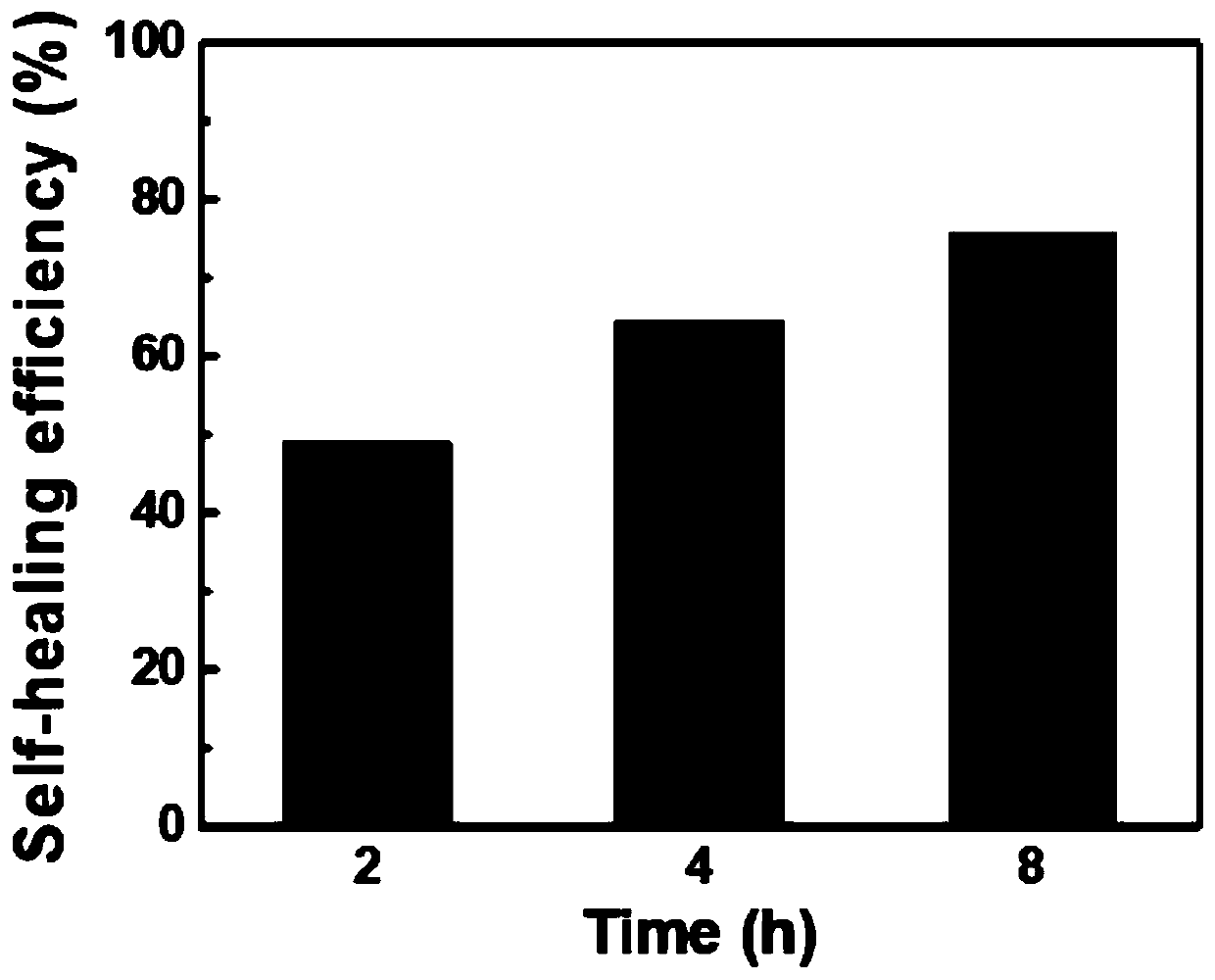

[0062] The self-healing effects of the double network hydrogels prepared in Example 2 and Comparative Example are shown in Table 4.

[0063] self-healing effect Example 2 excellent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com