Steering transmission mechanism for steering system of motor vehicle

A technology of transmission mechanism and steering transmission, which is applied in the direction of power steering mechanism, steering mechanism, steering control installed on the vehicle, etc. It can solve the problems of high manufacturing consumption and high manufacturing cost of geometric shape, and achieve effective torque transmission and low cost. The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

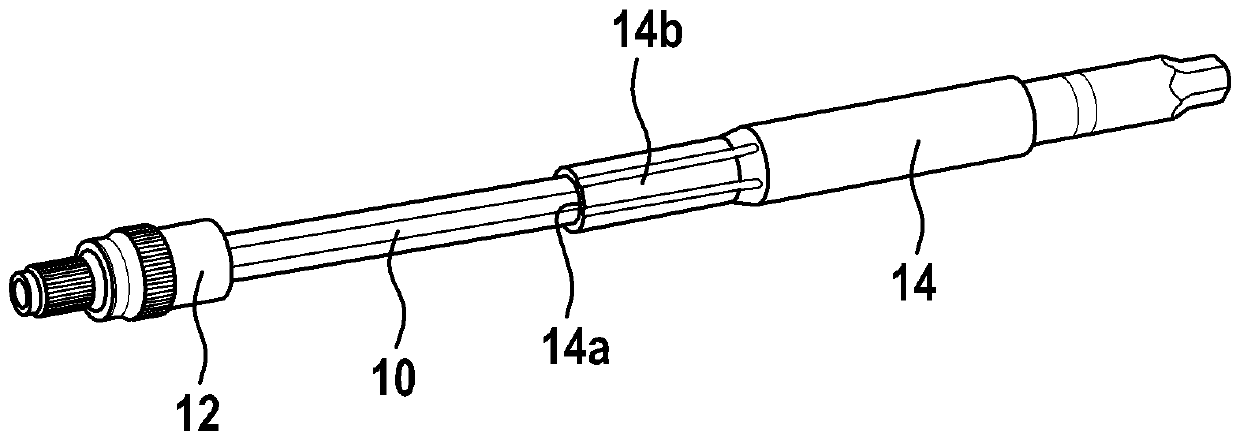

[0031] figure 1 A schematic diagram of a steering transmission mechanism for a steering system of a motor vehicle according to a preferred embodiment of the present invention is shown.

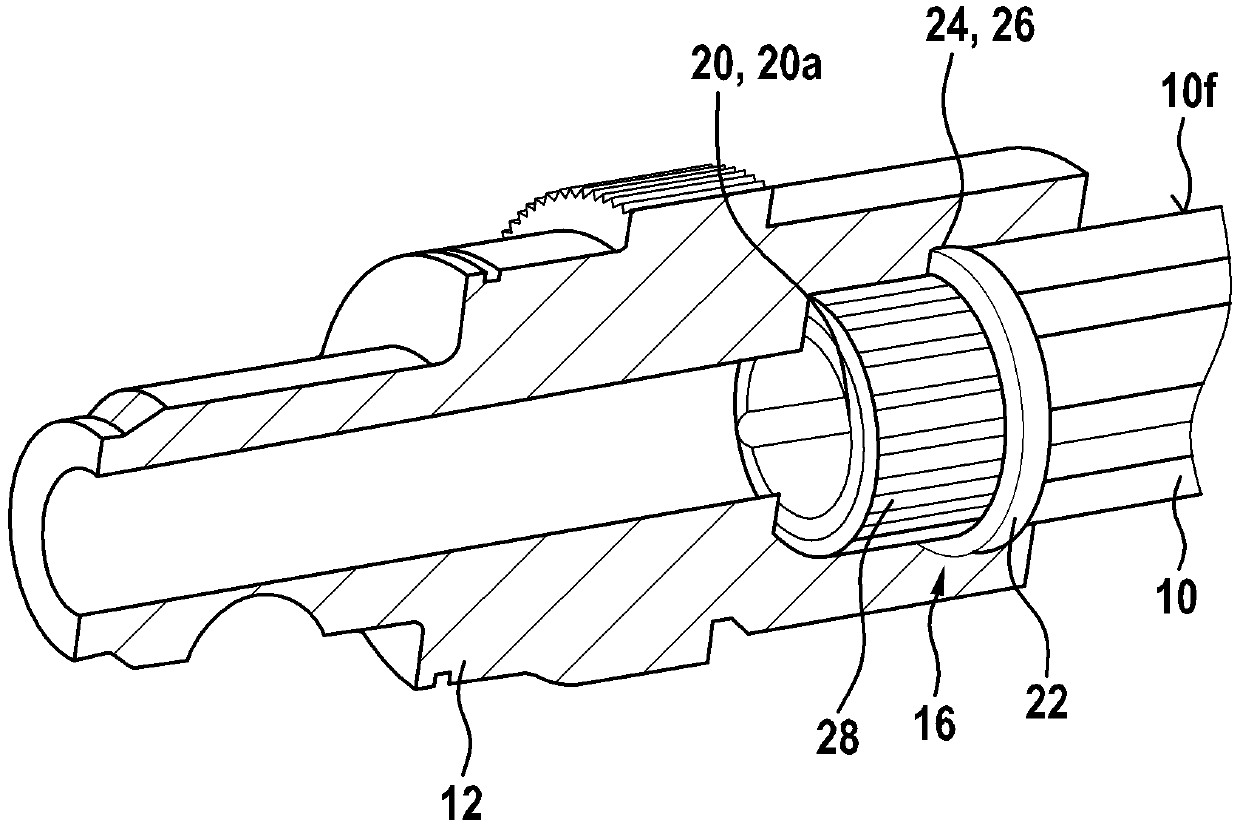

[0032] The steering transmission mechanism 1 for a steering system of a motor vehicle has a transmission mechanism input shaft 10 and a transmission mechanism output shaft 12. The transmission mechanism input shaft 10 can be connected to (at the first axial end section 10a) figure 1 (Shown schematically in) the steering spindle 14 is connected. In addition, the transmission mechanism input shaft 10 is connected to the transmission mechanism output shaft 12 at the second axial end section 10b in the assembled state.

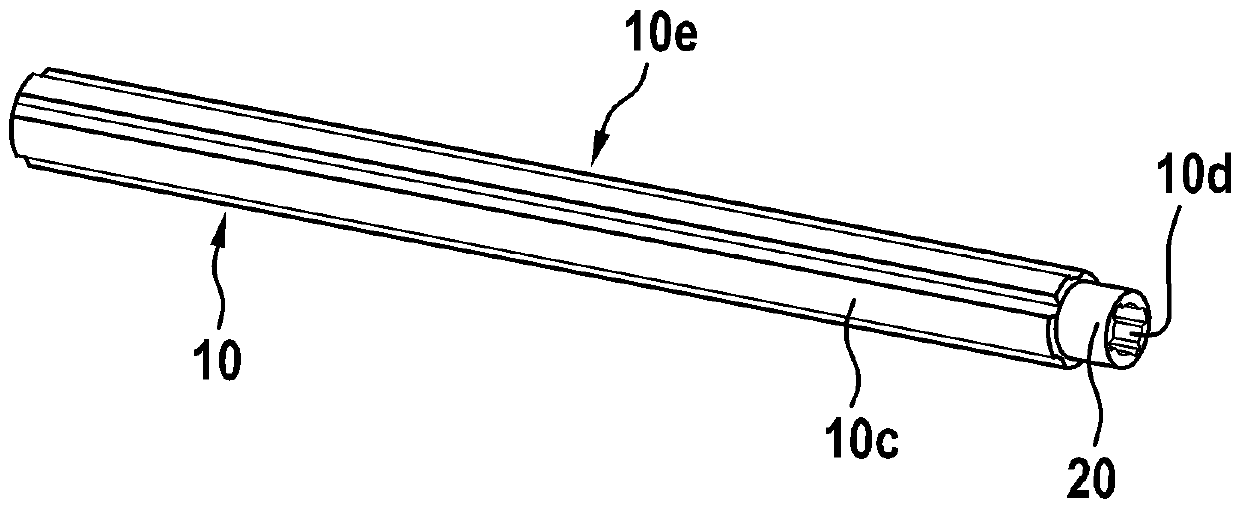

[0033] The transmission mechanism input shaft 10 has an external tooth portion 10c continuously configured along the axial direction A. The external tooth portion 10c is configured to transmit the torque applied to the transmission mechanism input shaft 10 by the steering spindle 14 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com