Clamp for static blade milling total length machining

A static blade, total length technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high equipment input cost, waste of resources, long manufacturing cycle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

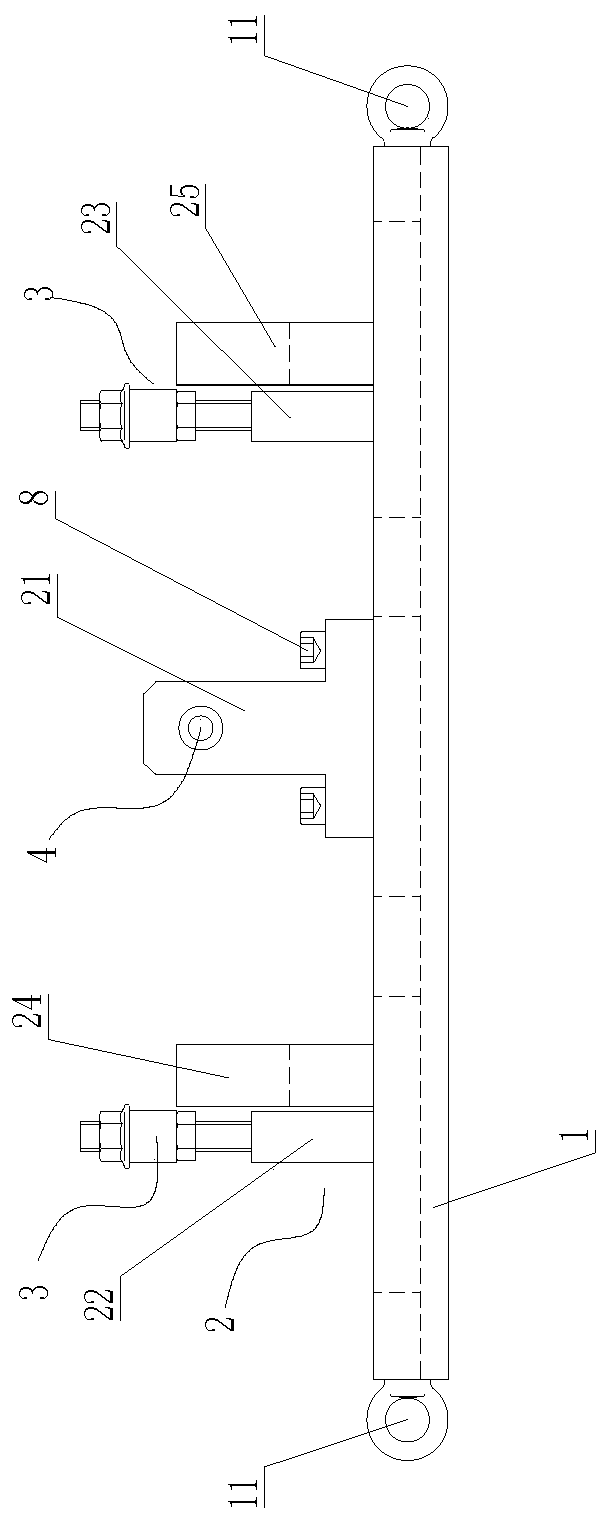

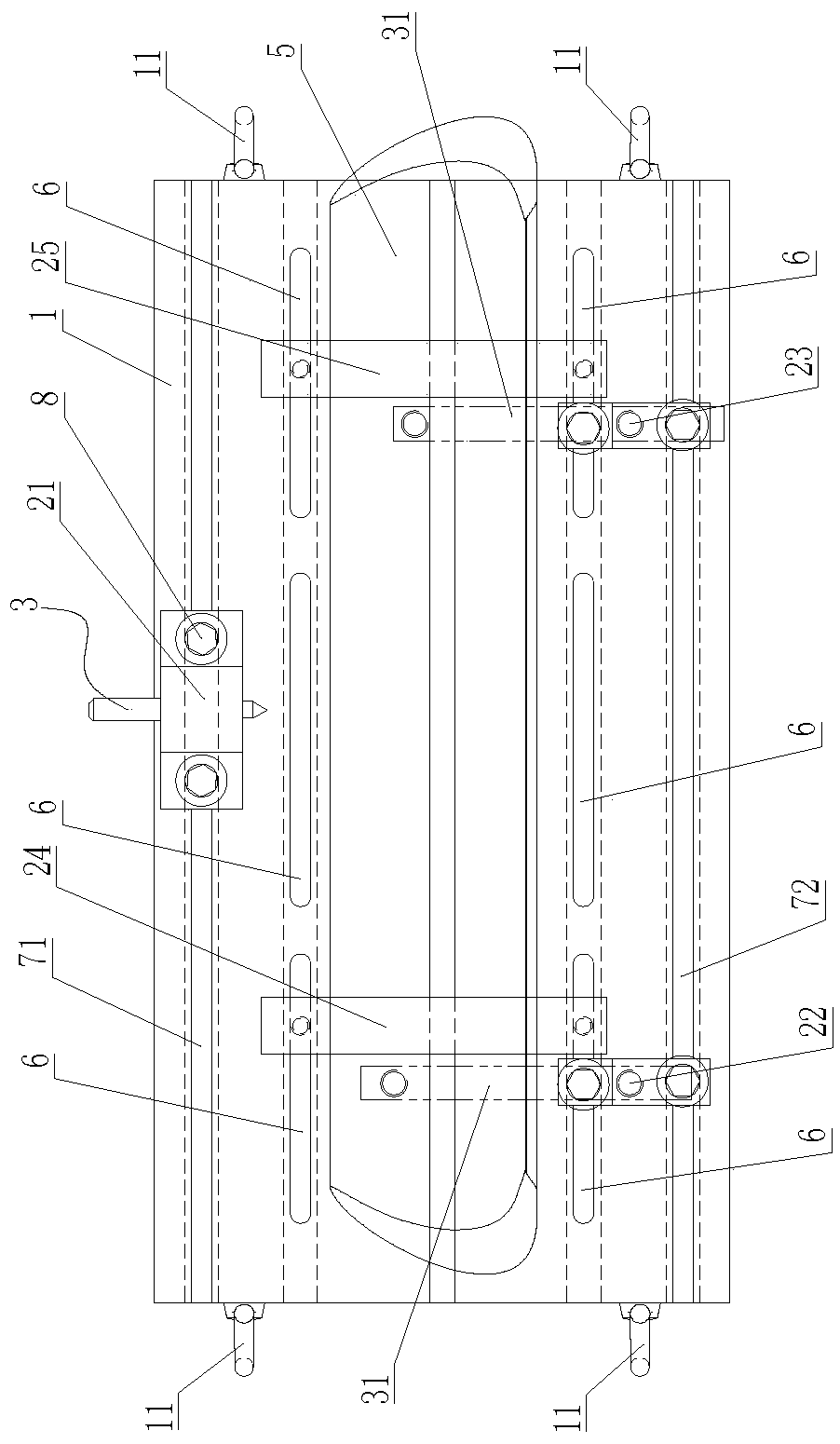

[0014] See Figure 1 to Figure 4 , a fixture for milling the overall length of a stationary blade, which includes a bottom plate 1, on which a blade profile positioning assembly 2, a tip positioning device 4, and a blade pressing device 3 are arranged, and the blade profile positioning assembly 2 includes three. Triangularly arranged support blocks: support block one 21, support block two 22, support block three 23 and two profile positioning blocks arranged in parallel: profile positioning block one 24, profile positioning block two 25, profile positioning block one 24. Profile positioning block 2 25 corresponds to the end faces on both sides of the blade 5 respectively, support block 1 21 is located at the top corner of the triangle, support block 2 22 and support block 3 23 are respectively located at the two feet of the triangle; There are at least two groups of waist-shaped holes 6 arranged in parallel. The waist-shaped holes 6 are arranged along the strip length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com