H-beam special-shaped billet loading and unloading gantry

A special-shaped billet, H-beam technology, applied in metal rolling, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenience, time-consuming access process, affecting the production rhythm of the rolling line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

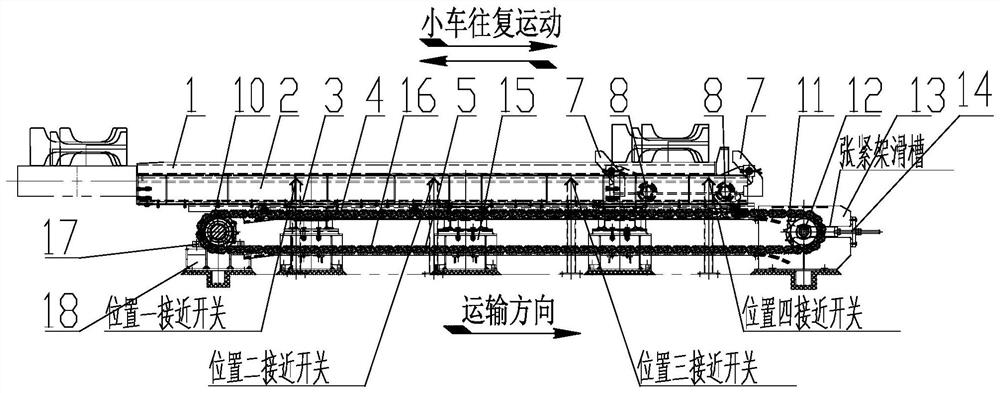

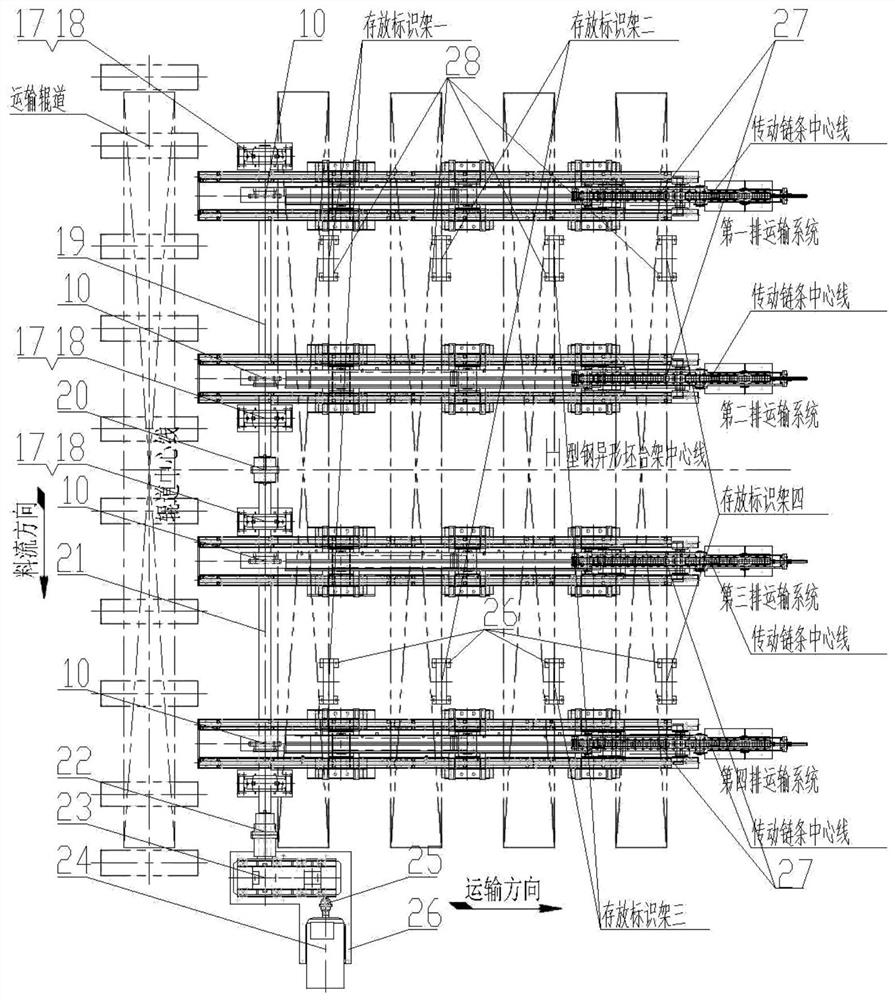

[0023] Such as Figure 1-7 As shown, the loading and unloading platform for H-shaped steel special-shaped blanks in this embodiment includes a conveying system, a trolley assembly, a tensioning system, a transmission system, and a storage label frame 27 .

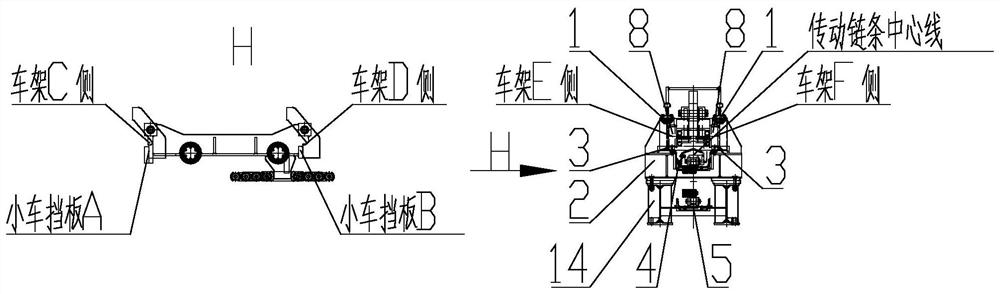

[0024]The conveying system is composed of 4 rows of conveying systems arranged side by side along the material flow direction, symmetrically arranged on the center line of the H-shaped steel special-shaped billet stand, and two rows are arranged on each side, and the structural composition of each row of the conveying system is the same. Take a row of transportation system as an example to illustrate its composition as figure 1 As shown, it includes a transport frame 2, an upper tow chain frame 4, a lower tow chain frame 5, a support slide rail 1, a track 3, and a base 15. The transport frame 2 is a symmetrical structure, and the track 3 is symmetrically fixed on the transport chain with the center line of the transmission...

Embodiment 2

[0028] On the basis of the above-mentioned embodiments, the transmission system includes a driving sprocket 10, a bearing seat 17, a bearing seat base 18, a first transmission shaft 19, a first shaft coupling 20, a second transmission shaft 21, a second shaft coupling Device 22, reducer 23, motor 24, the third coupling 25, transmission base 26, chain 16. The drive sprocket 10 on the upper side of the center line of the H-shaped steel special-shaped billet frame assembles the two ends of the first transmission shaft 19, and the first transmission shaft 19 is fixed on the bearing seat 17, and the bearing seat 17 is fixed on the bearing seat base 18. The drive sprocket 10 on the lower side of the center line of the H-shaped steel special-shaped billet gantry assembles the two ends of the second transmission shaft 21, and the second transmission shaft 21 below is fixed on the bearing seat 17, and the bearing seat 17 is fixed on the bearing seat base 18. The wheels 10 and the beari...

Embodiment 3

[0032] The process of hot billet blanking and pushing steel is as follows: Figure 7 As shown, in the first step, the four groups of trolleys move to the right, and the trolleys are controlled to stop at the side of the transport roller table through the signal of the proximity switch at control position five. The special-shaped billet is transported to the transport roller table; in the second step, the four groups of trolleys move to the left, and the start and stop of the trolley is controlled by the signal of the four proximity switches at the control position. Billet identification position 4, meanwhile, the special-shaped billet sent out by the continuous casting machine is transported to the transport roller table again; the third step, the four groups of trolleys move to the right, and the trolley is controlled to stop at the side of the transport roller table by the signal of the proximity switch at control position 5 ;The fourth step, the four groups of trolleys move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com