Wood plastic composite wine rack and processing method thereof

A technology of wood-plastic composite and processing method, which is applied in the direction of cocktail cabinets, applications, household appliances, etc., can solve the problems of weight, easy to mold, easy to corrode and rust, etc., and achieve the effect of moderate flexural modulus, low cost, and not easy to absorb water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

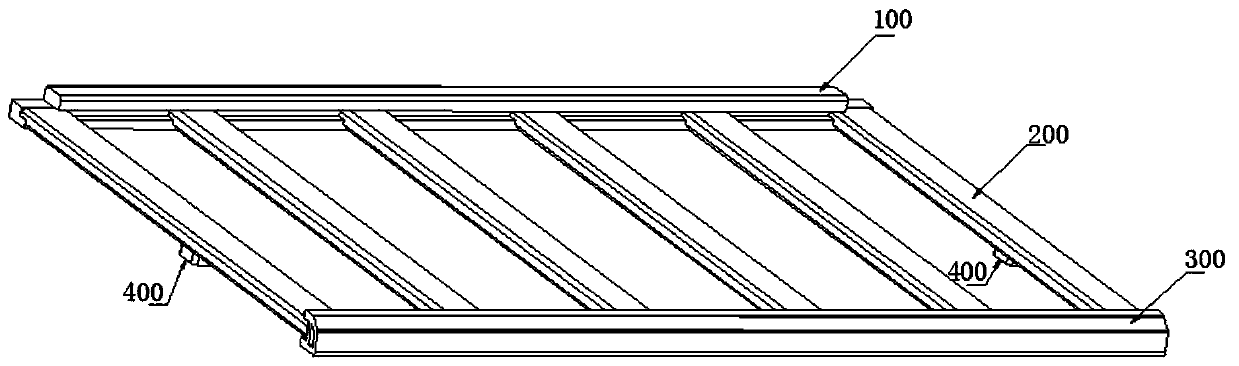

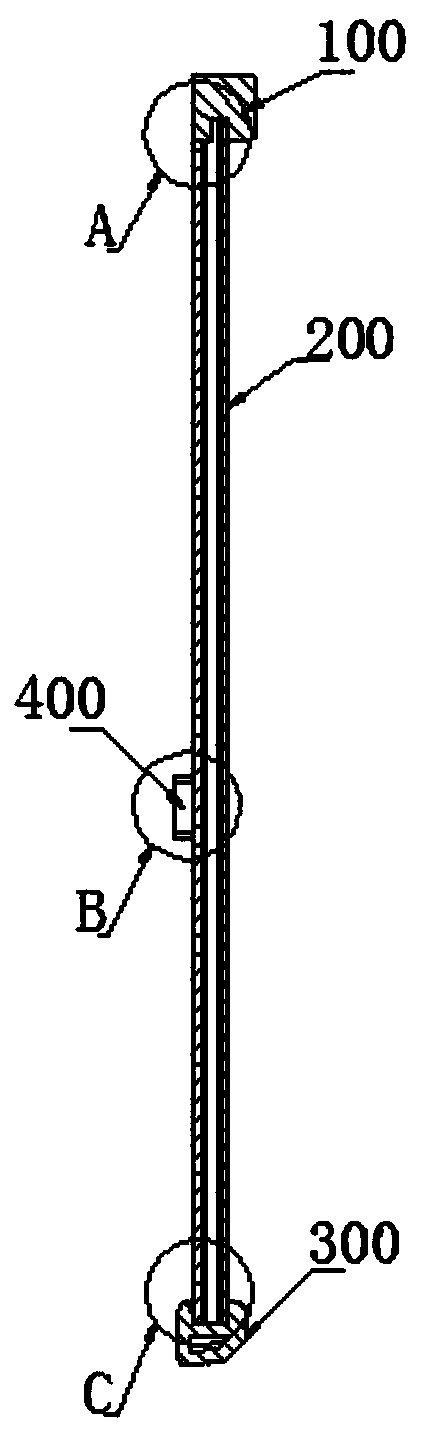

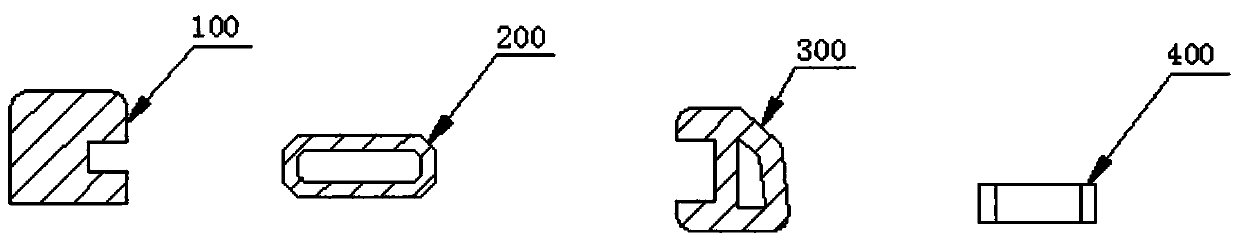

[0024] Such as figure 1 As shown, a wood-plastic composite wine rack includes a front trim strip 100, a middle trim strip 200, a rear trim strip 300 and a limit block 400, and the front trim strip 100, the middle trim strip 200 and the rear trim strip 300 are all linear Wood-plastic strips, the outer bottom surface of the front decorative strip 100 is provided with a U-shaped groove A along the axial central axis, and the outer top surface of the rear decorative strip 300 is provided with a U-shaped groove B along the axial central axis, and the front decorative strip 100 Set in parallel with the rear trim strip 300; the middle trim strip 200 is vertically and equidistantly distributed between the front trim strip 100 and the rear trim strip 300, and keep the middle trim strip 200 at both ends; the two ends of the middle trim strip 200 are respectively connected It is fixed in the U-shaped groove A and the U-shaped groove B; the outer surface of the middle decorative strip 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com