Method for nondestructively detecting draw resistance of cigarette sections of cigarette

A non-destructive testing, cigarette technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems affecting the calculation results of each segment of the cigarette, the calculation error of the suction resistance of the cut tobacco segment, and the change of the cigarette airflow, etc., and achieve the detection method and measurement data science. , reduce the calculation error, reduce the effect of coating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0037] The present invention is further described in conjunction with the following examples:

[0038] Choose 20 of a certain brand thin cigarette (circumference 17mm), and the specific operating steps of the method embodiment of the present invention are as follows:

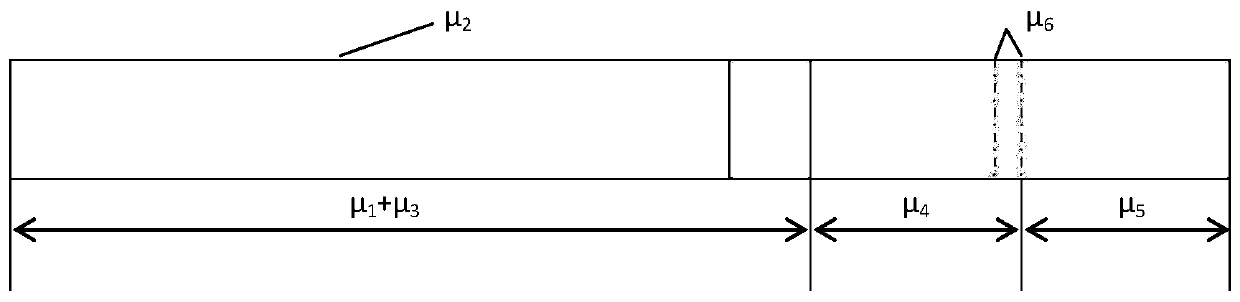

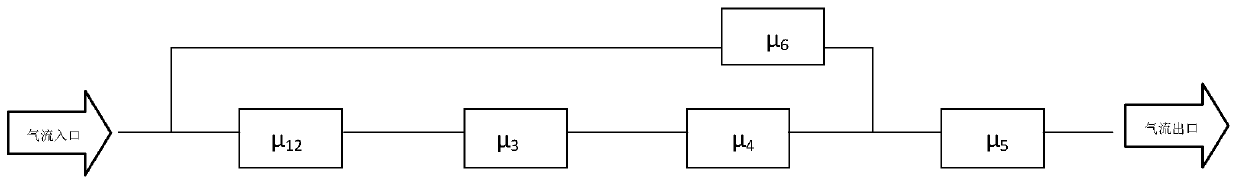

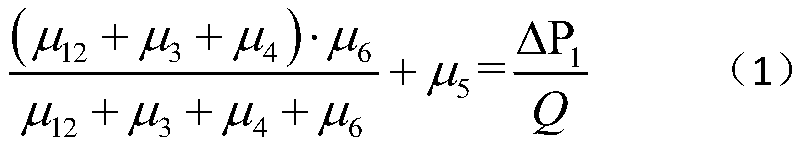

[0039] Step 1: Under the puffing flow rate Q of 17.5ml / s, the cigarette samples were not subjected to any treatment for the open draw resistance test, and the average draw resistance value ΔP1 of the corresponding 20 samples was 1707Pa, and the standard deviation was 58Pa. Detect the flow Q through the filter vent in this state 6 The average is 6.88mL / s, and the standard deviation is 0.25mL / s;

[0040] Step 2: Under the suction flow rate Q of 17.5ml / s, the cigarette sample is tested for resistance to draw under the conditions of closing the filter vent hole and opening the cigarette paper section. The method is to use 3M-clear tape for the filter vent hole Or coated with a latex tube of appropriate size, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com