Boiler main steam temperature control method with frequent fluctuations in power grid agc load command

A technology of main steam temperature and load command, applied in electric controllers, superheated temperature control, controllers with specific characteristics, etc. The effect of adjusting the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

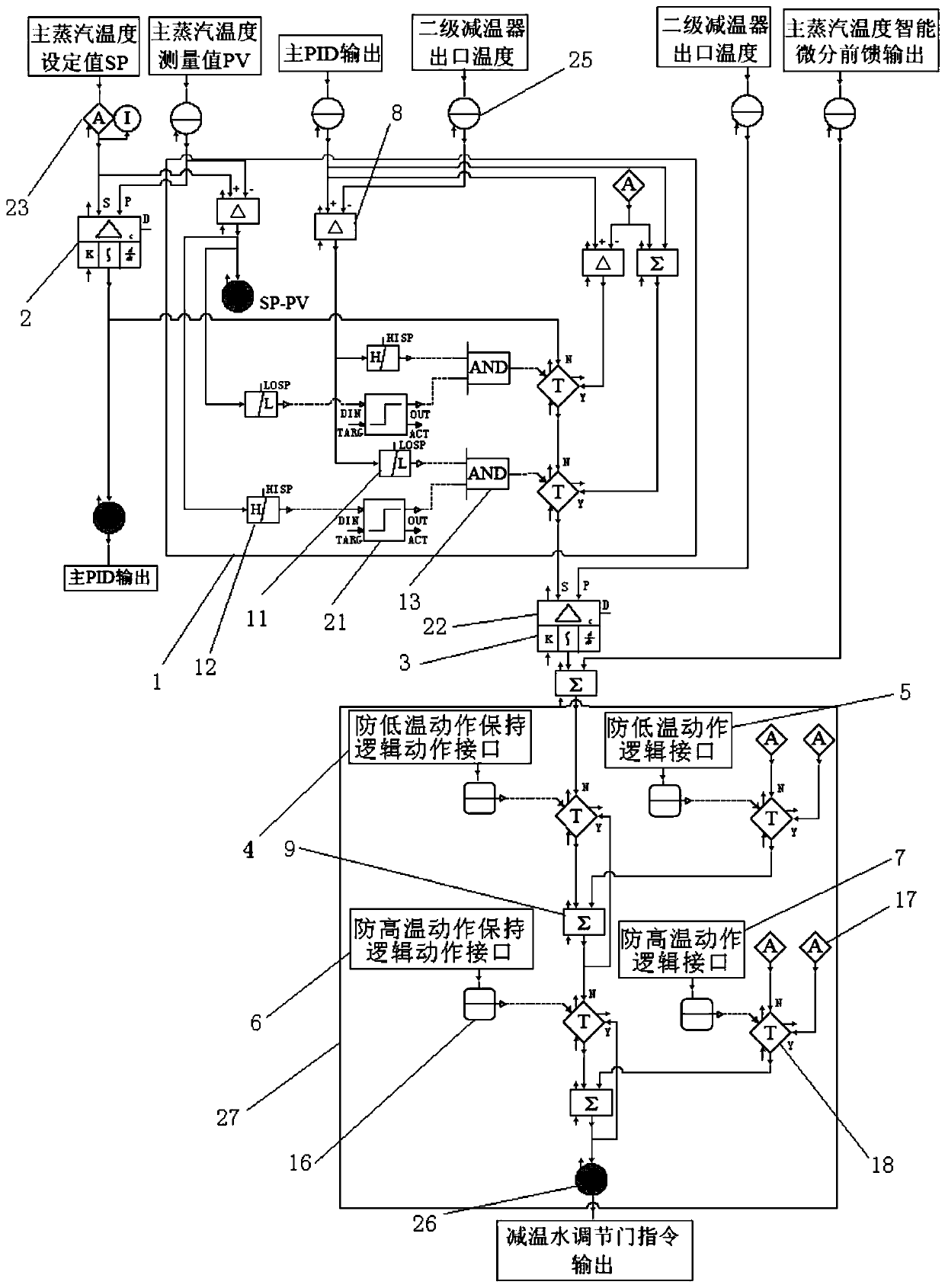

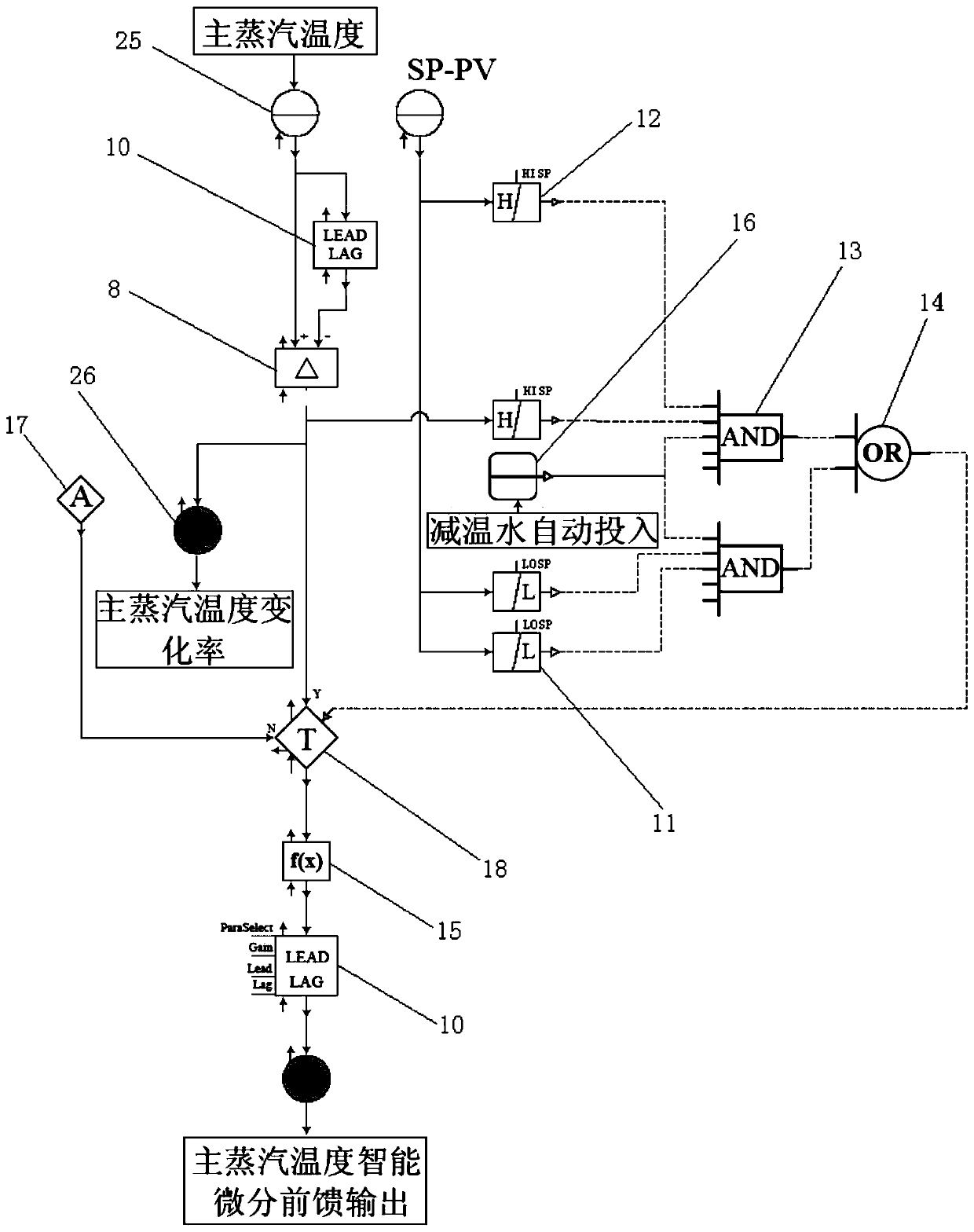

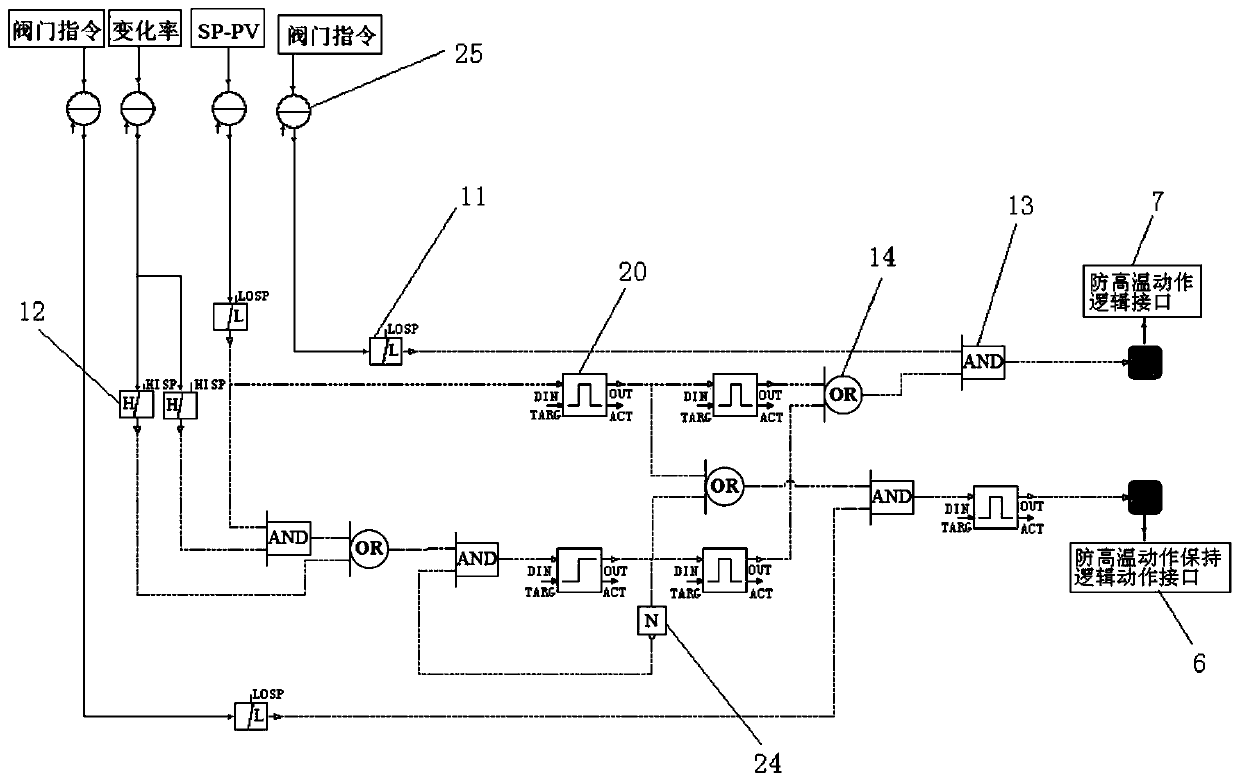

Method used

Image

Examples

Embodiment Construction

[0035] Large-scale thermal power units are generally put into AGC control system during normal production and operation. When the load control signal sent by the grid AGC system to the power plant fluctuates up and down in a small period, the boiler main steam temperature control system will produce overshoot under strong external disturbances. , causing the main steam temperature of the boiler to deviate from the set value, too high or too low. In actual operation, the main steam temperature control system of thermal power units generally adopts traditional PID cascade control, in which the secondary PID adopts positive action and the main PID adopts reverse action. When the AGC command signal fluctuates frequently, its control method will cause fatal problems to the system :

[0036] (1) The main PID and auxiliary PID of the cascade control system are adjusted in reverse, so that the control system cannot be quickly stabilized;

[0037] (2) After the AGC command signal fluc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com