Synchronous double-switch valve plate assembly and synchronous double-switch valve core

A double switch and valve plate technology, applied in the field of valve core, can solve the problems of poor pressure resistance of the valve core, large force of the moving valve plate to break away from the fit, unable to realize the function of water supply, etc., so as to improve the sealing effect and the sealing effect. Good, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

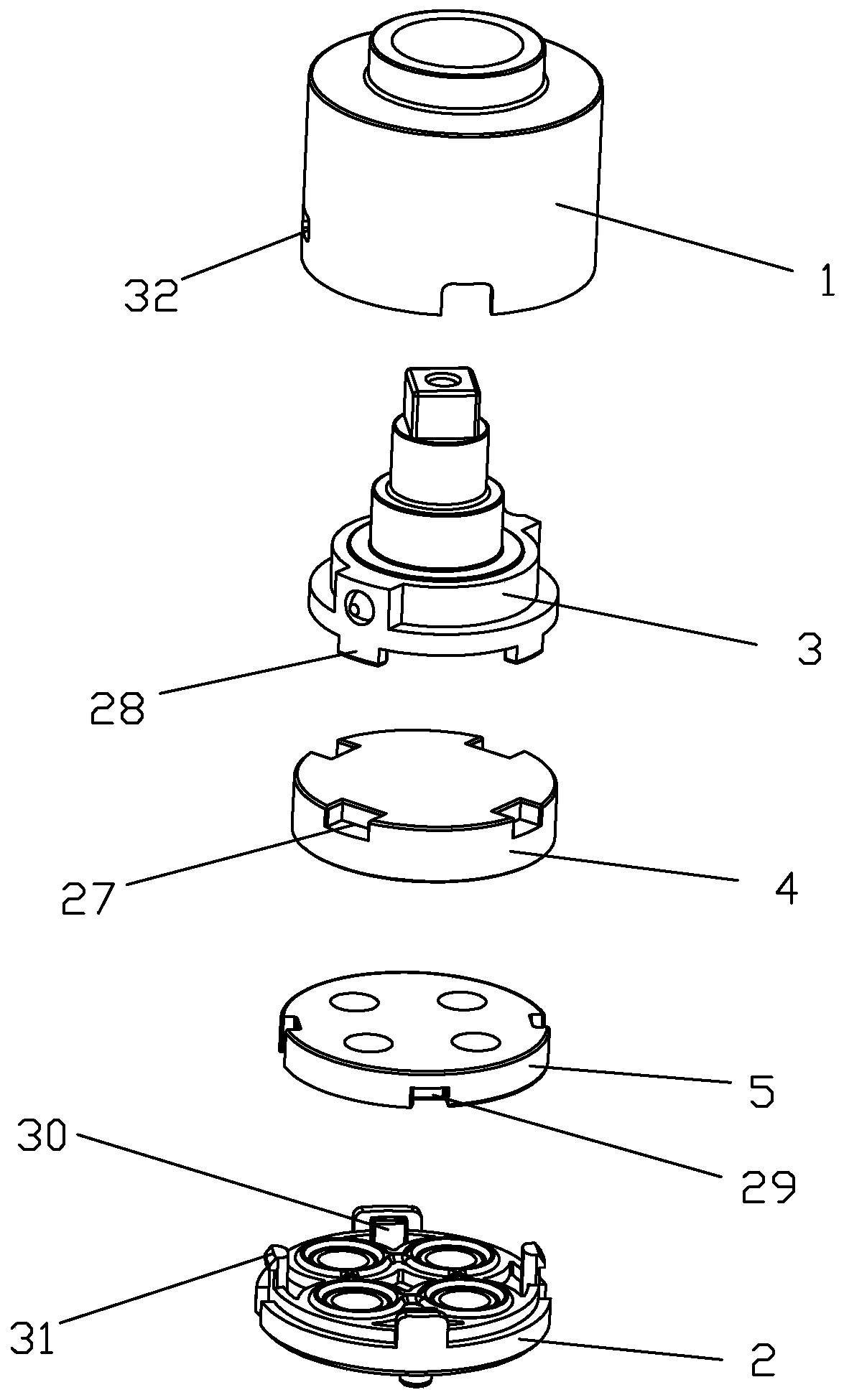

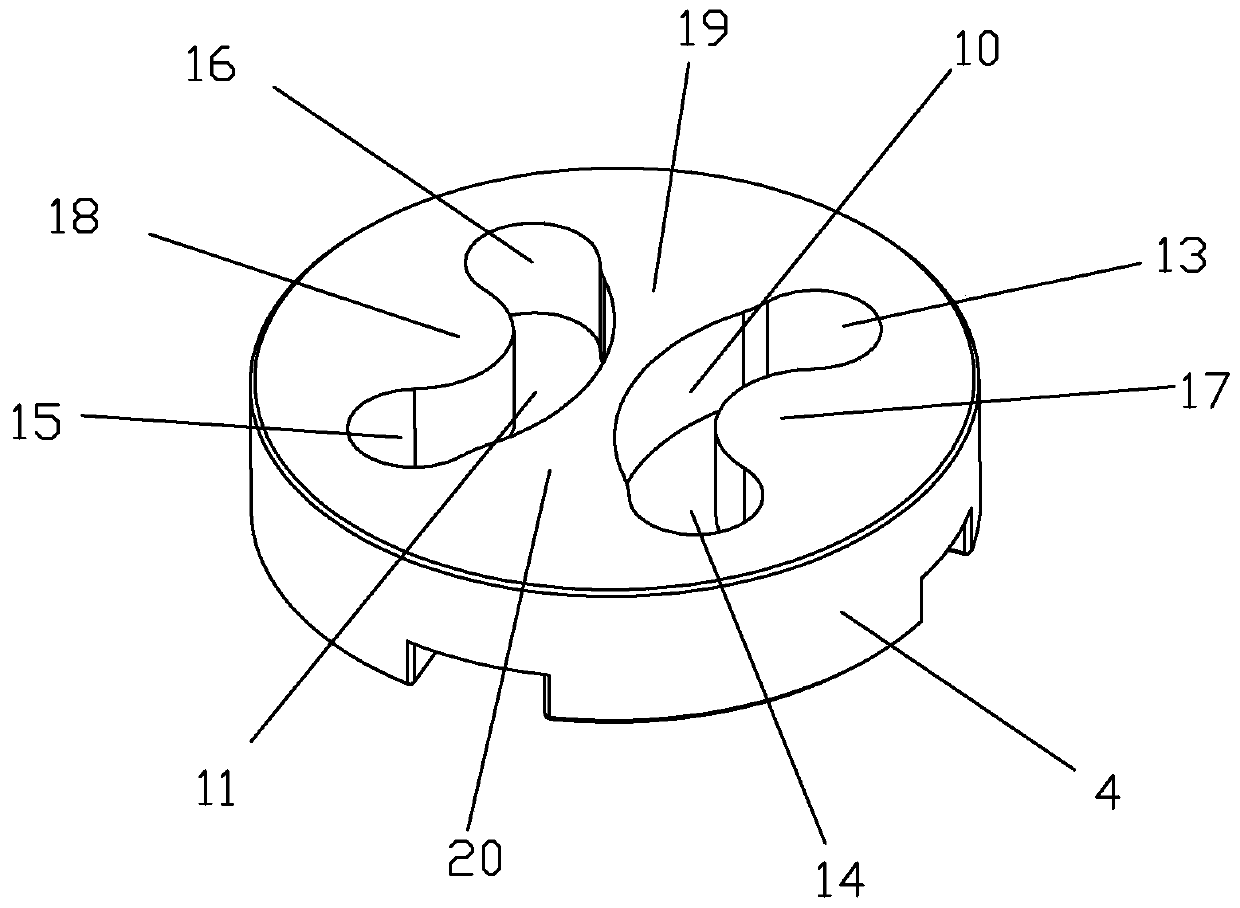

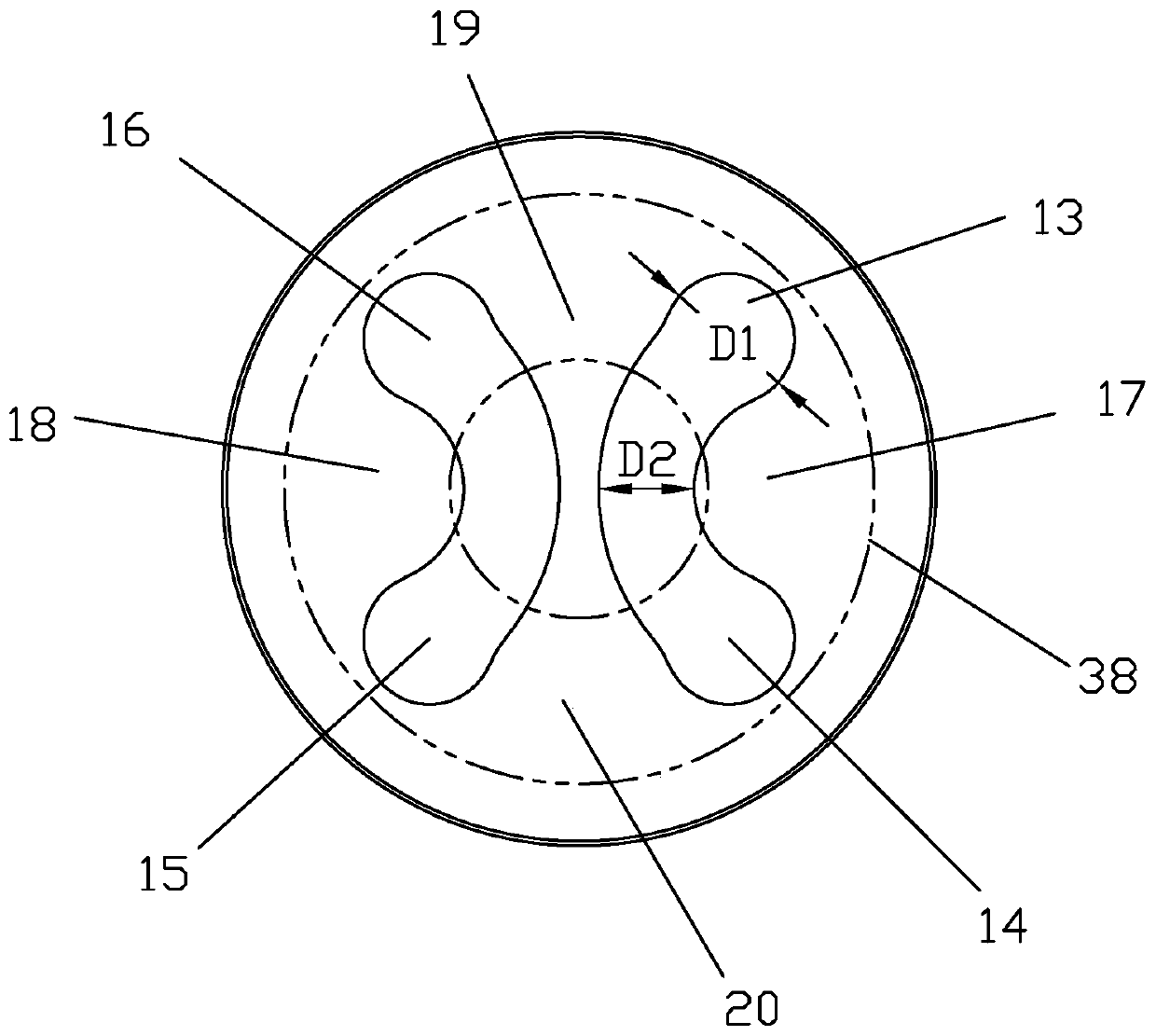

[0057] Example one, a synchronous dual-switch spool

[0058] Such as figure 1 As shown, a synchronous dual-switch spool includes a housing 1 and a base 2. A dial 3 is installed between the housing 1 and the base 2, and a synchronous dual-switch valve plate assembly is installed between the dial 3 and the base 2. The synchronous double switch valve plate assembly includes a moving valve plate 4 and a fixed valve plate 5. The dial 3, the movable valve disc 4 and the fixed valve disc 5 are compressed between the housing 1 and the base 2. The lower end of the dial 3 is provided with a clamping tooth 28, and the upper end of the movable valve disc 4 is provided with a clamping groove 27. The clamping teeth 28 and the clamping groove 27 cooperate with each other to fix the movable valve disc 4 on the lower end of the dial 3 circumferentially. The upper surface of the base 2 is provided with two clamping teeth 30, and the lower end of the fixed valve disc 5 is provided with a second c...

Embodiment 2

[0066] The second embodiment, a synchronous double switch spool,

[0067] Such as Figure 10~13 As shown, the difference between the second embodiment and the first embodiment is mainly in the number of limit slots 24 on the housing 1. The number of limit slots 24 on the second embodiment is three, which are respectively the closed limit slot 36 and the full limit slot 24. The limit slot 35 and the limit slot 37 of the maximum water supply state are opened.

[0068] When in use, another adjacent water inlet and outlet through hole is connected to the water inlet pipe, such as Picture 12 As shown, the water inlet and outlet through holes 6 are connected with a water inlet pipe, the water inlet and outlet through holes 7 are connected with an outlet water channel; the water inlet and outlet through holes 29 are connected with another water inlet pipe, and the water inlet and outlet through holes 3 8 is connected to another discharge water pipeline, and the valve core is set to be in...

Embodiment 3

[0072] The third embodiment, a synchronous double switch spool,

[0073] Such as Figure 14 As shown, the difference between the third embodiment and the first embodiment lies in the shape of the water passage groove on the movable valve plate 4, and the water passage groove 1 10 and the water passage groove 2 11 in the embodiment 3 are both V-shaped. Figure 15 It is a schematic diagram of the relative positions of the movable valve disc 4 and the fixed valve disc 5 when the valve core is in the closed state.

[0074] When only the switch function is needed, the two water inlet pipes are connected with the diagonally arranged water inlet and outlet through holes 6 and 8 through the inlet and outlet. The outlet pipe 1 is connected with the inlet and outlet through holes 7 and the outlet pipe 2 is connected with the inlet and outlet. The water through holes 29 are connected. Water can be discharged when the movable valve disc 4 rotates clockwise or 45 degrees counterclockwise.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com