Piston seal part and machining process thereof

A technology of piston seals and seals, which is applied to piston rings, pump components, household components, etc., can solve the problem of non-wearability of concrete pistons, and achieve the effects of ensuring product quality, reducing costs, and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

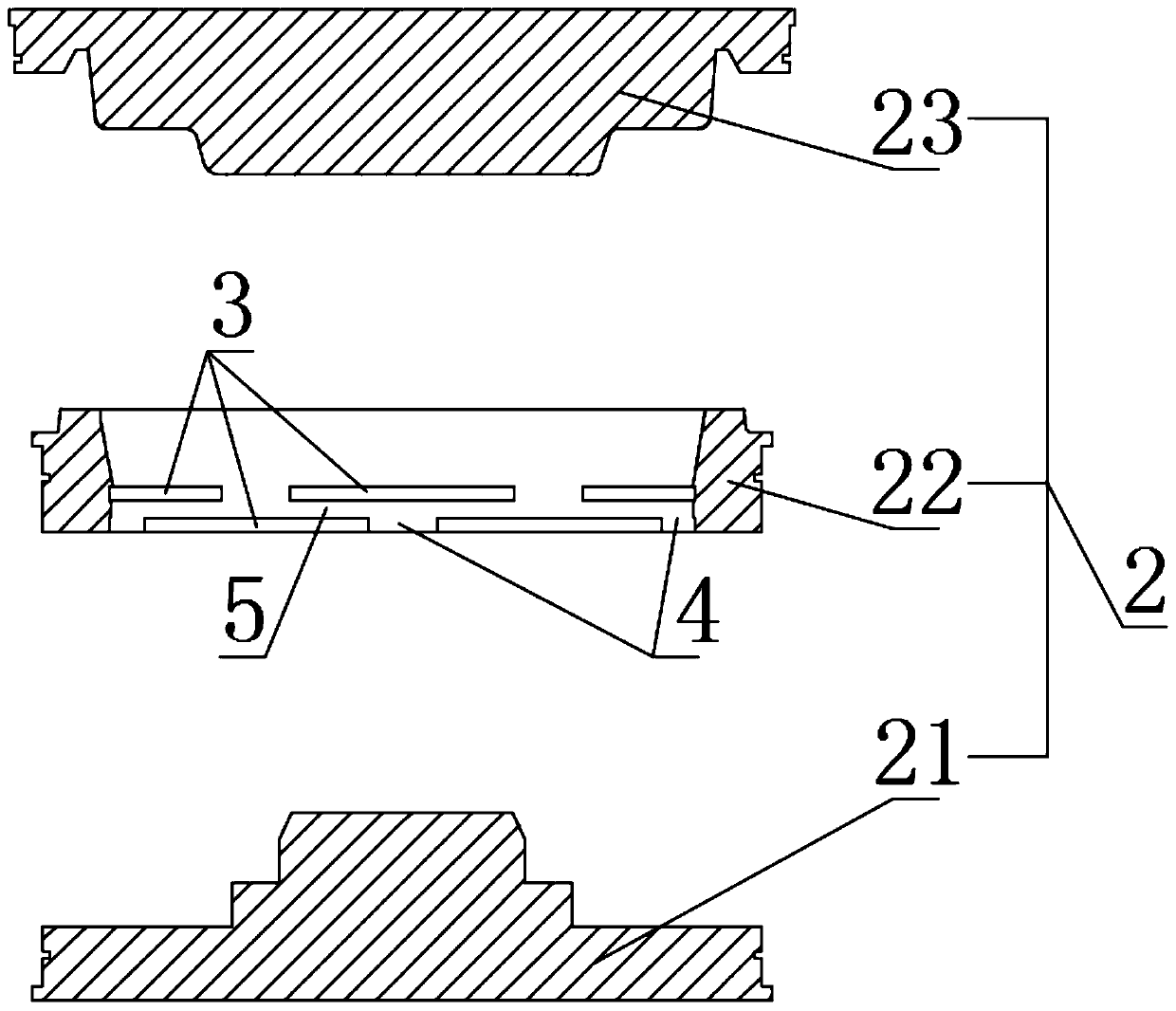

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

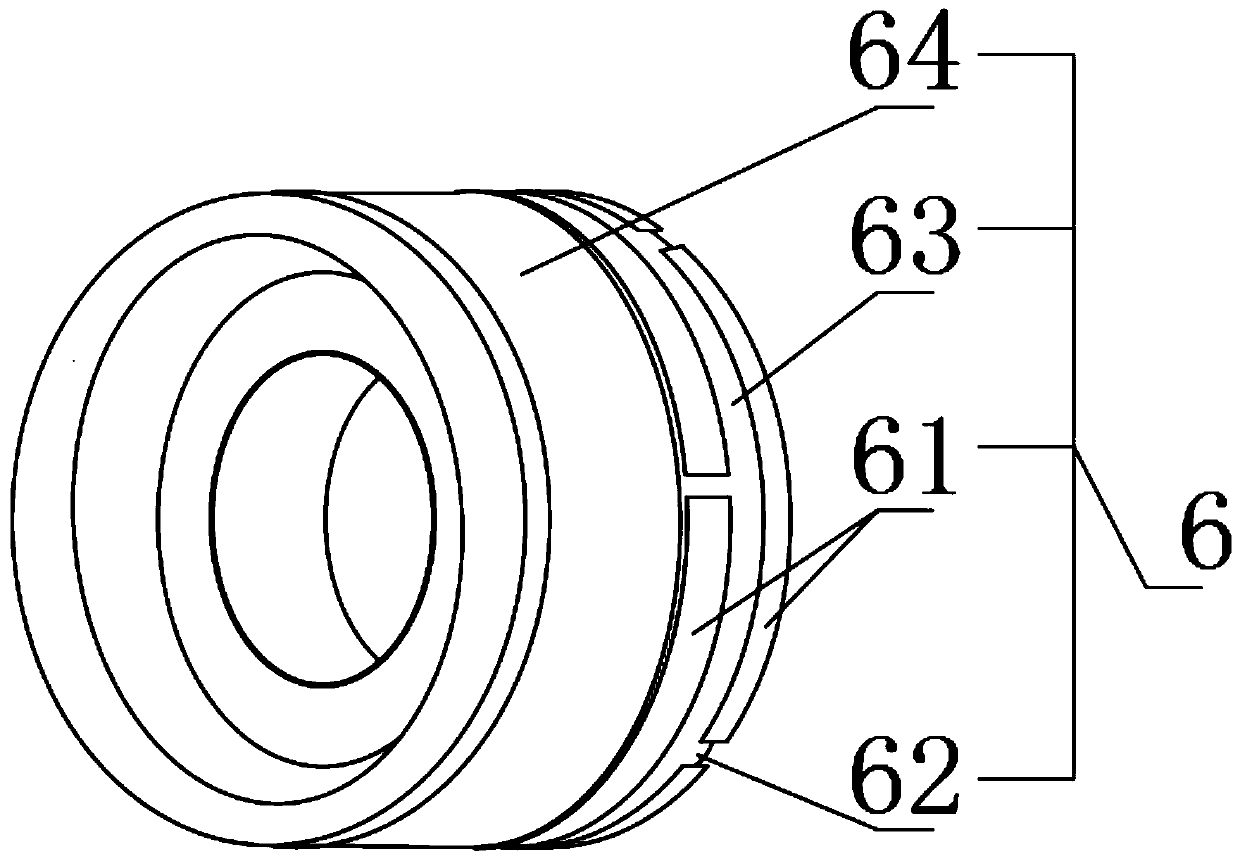

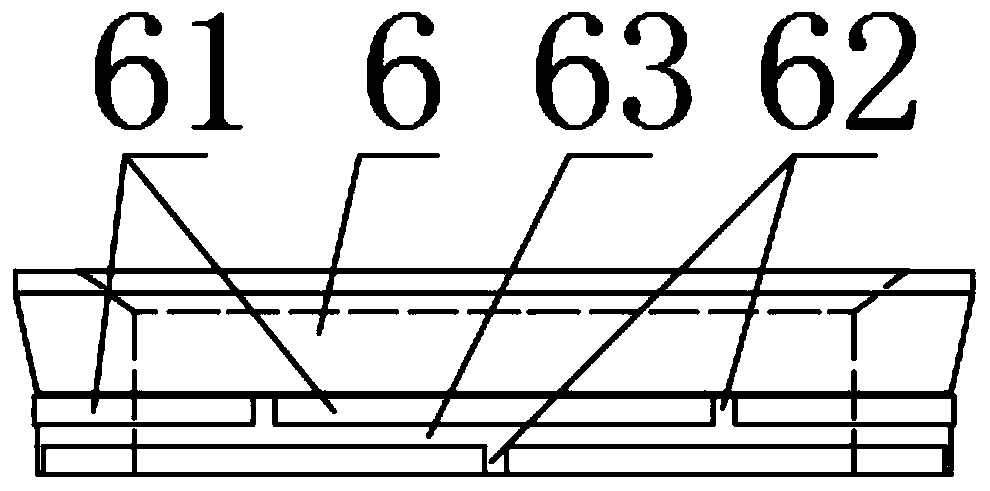

[0029] A piston seal, comprising a seal body 64, an annular protruding sealing strip 61 is provided under the seal body 64, and a slot 62 is provided on the sealing strip 61 to disconnect the sealing strip 61. Slot 62 is perpendicular to sealing strip 61, and slot 62 is as figure 1 or figure 2 shown.

[0030] During use, due to the harsh working environment and high temperature and high pressure of the piston, the concrete piston will deform in the cylinder under the influence of pressure. The top of the concrete piston is in contact with the concrete, the bottom is connected with the connecting rod and the cavity, and the top end pushes the concrete. It can play a good sealing effect. When stretching back, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com