Rapid repair mortar for partial damage of concrete base and preparation method thereof

A concrete base and repair mortar technology, which is applied in the field of building materials, can solve problems such as insufficient shear bond strength, failure of concrete repair, damage to new and old concrete bonded composite structures, etc., to improve waterproof performance and chloride ion penetration resistance , Improve physical and mechanical properties, improve the effect of shear bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

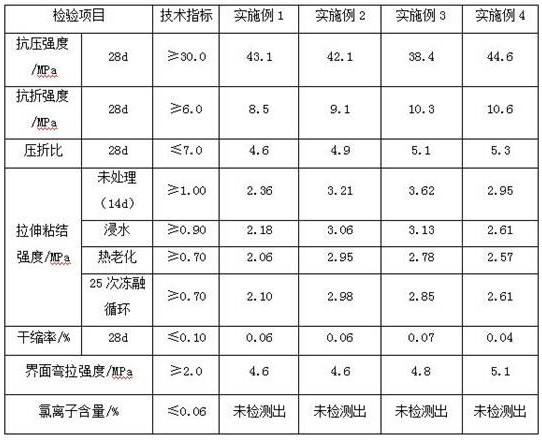

Examples

Embodiment 1

[0032] Raw materials (by weight):

[0033] 50 parts of aggregate, 20 parts of composite cement, 4 parts of styrene-butadiene emulsion, 1 part of coupling agent, 0.5 part of composite shrinkage reducing agent, 0.1 part of water-repellent agent, 0.1 part of graphene dispersion, and 0.1 part of polypropylene fiber.

[0034] Preparation:

[0035] S1, first dilute the styrene-butadiene emulsion with water, the volume ratio of the styrene-butadiene emulsion to water is 1:5-8, then add the carboxylated graphene oxide dispersion, and stir until it is completely uniform to obtain a mixture solution;

[0036] S2, aggregate, composite cement, coupling agent, composite shrinkage reducing agent, water repellent and polypropylene fiber are added to the mixer in proportion and stirred for 3-5 minutes; in the stirring state, slowly pour the mixture solution in step S1 In the mixer, after adding the mixture solution, continue to stir for 3-5 minutes to obtain a quick repair mortar for local d...

Embodiment 2

[0038] 70 parts of aggregate, 30 parts of composite cement, 8 parts of styrene-butadiene emulsion, 3 parts of coupling agent, 2 parts of composite shrinkage reducing agent, 0.5 part of water-repellent agent, 0.5 part of graphene dispersion, and 0.5 part of polypropylene fiber.

[0039] The preparation method of the local damage quick repair mortar of the above concrete base is the same as that of Example 1.

Embodiment 3

[0041] 60 parts of aggregate, 25 parts of composite cement, 5 parts of styrene-butadiene emulsion, 2 parts of coupling agent, 1 part of composite shrinkage reducing agent, 0.2 part of water-repellent agent, 0.2 part of graphene dispersion, and 0.2 part of polypropylene fiber.

[0042] The preparation method of the local damage quick repair mortar of the above concrete base is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com