A kind of oil well cement suitable for salt-gypsum layer cementing operation and preparation method thereof

A technology for oil well cement and salt gypsum layer, applied in the field of oil well cement, can solve the problems of admixtures interfering with normal action, ineffective resistance, shortening the service life of oil and gas wells, etc. Advantages and use effects, the effect of preventing formation salt corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

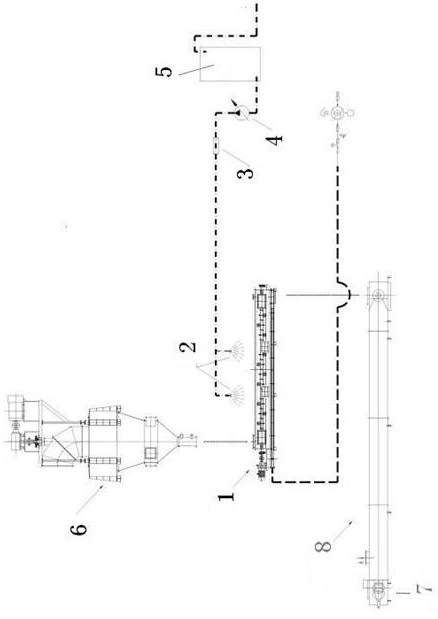

Image

Examples

example 1

[0036] The amount of cement clinker is 95%, the amount of gypsum is 5%, the amount of retarder is 0.1 per ten thousand, the amount of dispersant is 0.1%, and the amount of atomized water is 0.20%. Use underground brine (salt content 18%), when the water-solid ratio is 0.44, the fluidity of the cement slurry is 200mm, and after standing for 15 minutes, the fluidity is 180mm. After the cement slurry is heated to 80°C, the fluidity is 180mm. The curing time is 133min, the strength is 4.0MPa at normal pressure 38°C for 8h, the strength is 17.2MPa at normal pressure at 60°C for 8h, and the free liquid is 5.0%.

example 2

[0038] The amount of cement clinker is 96%, the amount of gypsum is 4%, the amount of retarder is 0.2 per ten thousand, the amount of dispersant is 0.25%, and the amount of atomized water is 0.40%. Use underground brine (salt content 18%), when the water-solid ratio is 0.44, the fluidity of the cement slurry is 210mm, and after standing for 15 minutes, the fluidity is 200mm. After the cement slurry is heated to 80°C, the fluidity is 200mm. The curing time is 140min, the strength is 4.5MPa at normal pressure 38°C for 8h, the strength at normal pressure is 60°C for 8h is 19.1MPa, and the free liquid is 4.5%.

example 3

[0040] The amount of cement clinker is 97%, the amount of gypsum is 3%, the amount of retarder is 0.3 per ten thousand, the amount of dispersant is 0.35%, and the amount of atomized water is 0.70%. Use underground brine (salt content 18%), when the water-solid ratio is 0.44, the fluidity of the cement slurry is 220mm, and after standing for 15 minutes, the fluidity is 200mm. After the cement slurry is heated to 80°C, the fluidity is 200mm. The curing time is 140min, the strength is 4.7MPa at normal pressure 38°C for 8h, the strength is 21.7MPa at normal pressure at 60°C for 8h, and the free liquid is 3.4%.

[0041] From the above example and its results, it can be known that when applied to salt-gypsum layer cementing, the fluidity of the cement slurry is ≤220mm, and after a period of time, the fluidity is improved, and the thickening time at 52°C and 35.6MPa is in 130-140min, there will be no flash condensation, and it is also suitable for high-temperature salt-gypsum layers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com