Biological deodorization method used in sludge dehydration workshop

A biological deodorization and sludge dehydration technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as easy loss of nitrogen, acid rain, and reduction of sludge nutrients, and achieve The effect of preventing nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment provides a biological deodorization method in a sludge dehydration workshop, specifically:

[0017] Add chemical nitrogen retaining agent to sludge, said chemical nitrogen retaining agent includes sludge activated carbon, Mg(OH) 2 、H 3 PO 4 and H 2 O, by mass ratio sludge activated carbon: Mg(OH) 2 :H 3 PO 4 :H 2 O=18:7:15:60.

Embodiment 2

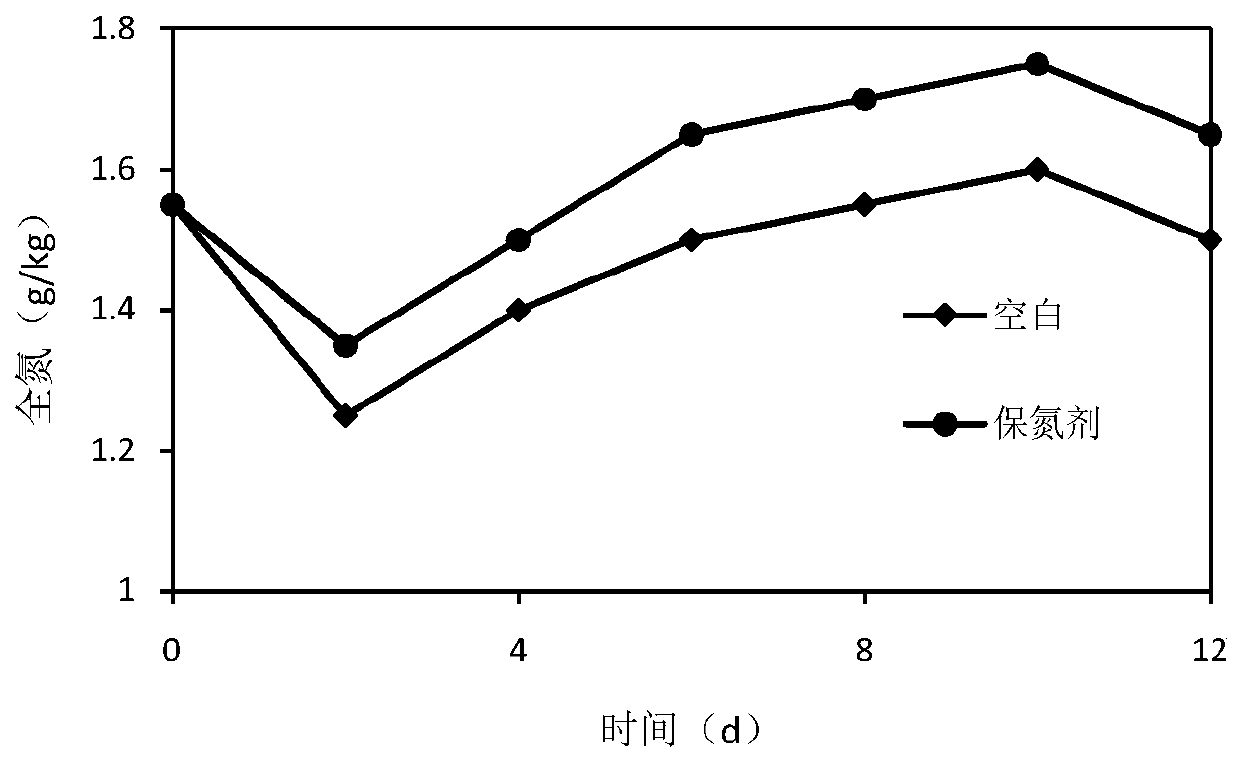

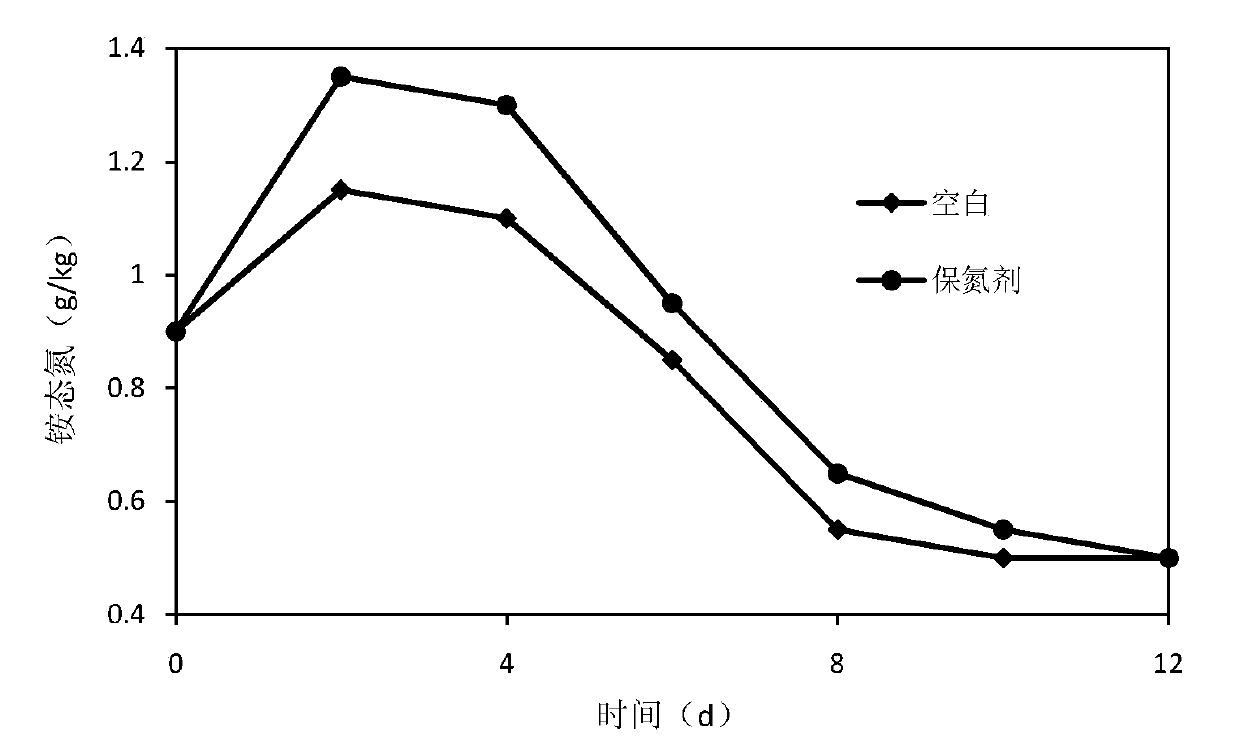

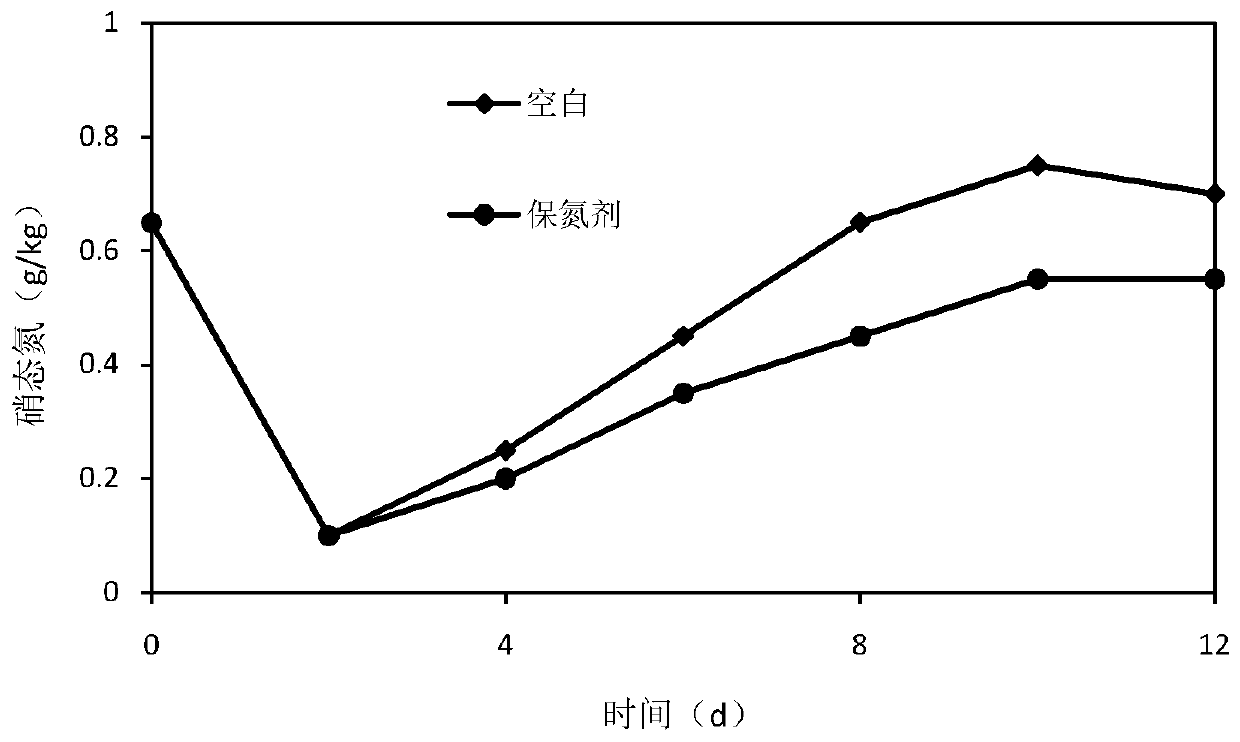

[0019] In this example, the performance of the method described in Example 1 is further verified through experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com