Microbial synergistic compound fertilizer and preparation method thereof

A compound fertilizer and microbial technology, which is applied in the field of microbial synergistic compound fertilizer and its preparation, can solve the problems of decreased survival rate of microorganisms, failure to function, high humidity of fertilizer, etc., achieve sterilization and degradation of heavy metals, improve fertilizer utilization rate, The effect of improving the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

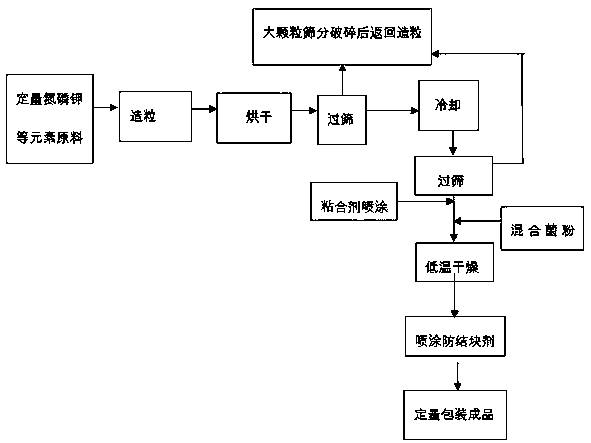

Image

Examples

Embodiment 1

[0040] This embodiment provides a microbial synergistic compound fertilizer, which is prepared according to the following method:

[0041] S1: Granulate urea, ammonium monohydrogen phosphate, and potassium nitrate in a drum, dry them, pass through a 6-mesh sieve, sieve and crush the large particles and return to granulation, and sieve the small particles for the first low-temperature drying. Dry at 40-50°C, pass through a 12-mesh sieve again, sieve the small particles and return to granulation, keep the large particles and sieve to obtain compound fertilizer granules with a particle size of 1.5mm-2.5mm.

[0042] S2: In the drum, make the compound fertilizer granules in a fluidized state, and use a pressure pump to evenly spray the adhesive onto the surface of the fluidized compound fertilizer granules. The binder is formed by dissolving alginic acid in potassium hydroxide aqueous solution, and the viscosity is 400mPa.s.

[0043] S3: Spray the mixed bacterial powder containing...

Embodiment 2

[0046] This embodiment provides a microbial synergistic compound fertilizer, which is prepared according to the following method:

[0047] S1: Granulate urea, ammonium monohydrogen phosphate, and potassium nitrate in a drum, dry them, pass through a 6-mesh sieve, sieve and crush the large particles and return to granulation, and sieve the small particles for the first low-temperature drying. Dry at 45~50°C, pass through a 12-mesh sieve again, sieve the small particles and return to granulation, keep the large particles and sieve to obtain compound fertilizer granules with a particle size of 1.5mm~2.5mm.

[0048] S2: In the drum, make the compound fertilizer granules in a fluidized state, and use a pressure pump to evenly spray the adhesive onto the surface of the fluidized compound fertilizer granules. The adhesive is formed by dissolving alginic acid in potassium hydroxide aqueous solution, and the viscosity is 300mPa.s.

[0049] S3: At 42-45°C, when the adhesive has not yet...

Embodiment 3

[0052] This embodiment provides a microbial synergistic compound fertilizer, which is prepared according to the following method:

[0053] S1: Granulate urea, ammonium monohydrogen phosphate, and potassium nitrate in a drum, dry them, pass through a 6-mesh sieve, sieve and crush the large particles and return to granulation, and sieve the small particles for the first low-temperature drying. Dry at 45~50°C, pass through a 12-mesh sieve again, sieve the small particles and return to granulation, keep the large particles and sieve to obtain compound fertilizer granules with a particle size of 1.5mm~2.5mm.

[0054] S2: In the drum, make the compound fertilizer granules in a fluidized state, and use a pressure pump to evenly spray the adhesive onto the surface of the fluidized compound fertilizer granules. The adhesive is formed by dissolving alginic acid in potassium hydroxide aqueous solution, and the viscosity is 500mPa.s.

[0055] S3: At 42~45°C, before the adhesive is solidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com