Production method of corrugated board

A technology of corrugated cardboard, production method, applied in the direction of adhesive type, adhesive additive, machining/deformation, etc., which can solve problems such as poor bonding, production loss, blocking or parking of post-processing equipment, and achieve adhesive bonding High strength, high strength and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

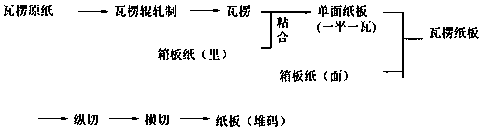

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] figure 1 It is a flow chart of the production process of the present invention. Such as figure 1 Shown, corrugated paper production method of the present invention comprises the steps:

[0026] Step 1: Glue making;

[0027] (1) Inject 1150 parts of hot water at 28~32℃ into the mother tank, and add three kinds of additives (13 parts of strengthening agent first, then 5 parts of borax, and finally 3~5 parts of caustic soda) into the mother tank, Stir for 3~5 minutes;

[0028] (2) Add 300 parts of starch to the mother bucket while stirring, and stir for another 9 to 12 minutes;

[0029] (3) Add caustic soda solution with a caustic soda content of 7.5 parts to the mother bucket, stir for 15 minutes, and measure the paste viscosity with a 7# measuring cup to make it reach 27~29 seconds;

[0030] (4) Add 3.5~4.5kg of stabilizer, stir for 3~5 minutes, measure the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com