Toggle type mechanical edge covering press

A press and toggle-type technology, applied in the field of presses, can solve the problems of high equipment manufacturing cost, oil leakage of hydraulic hemming machines, high energy consumption, etc., achieve adjustable synchronous motion precision, improve stress conditions, and work strokes big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

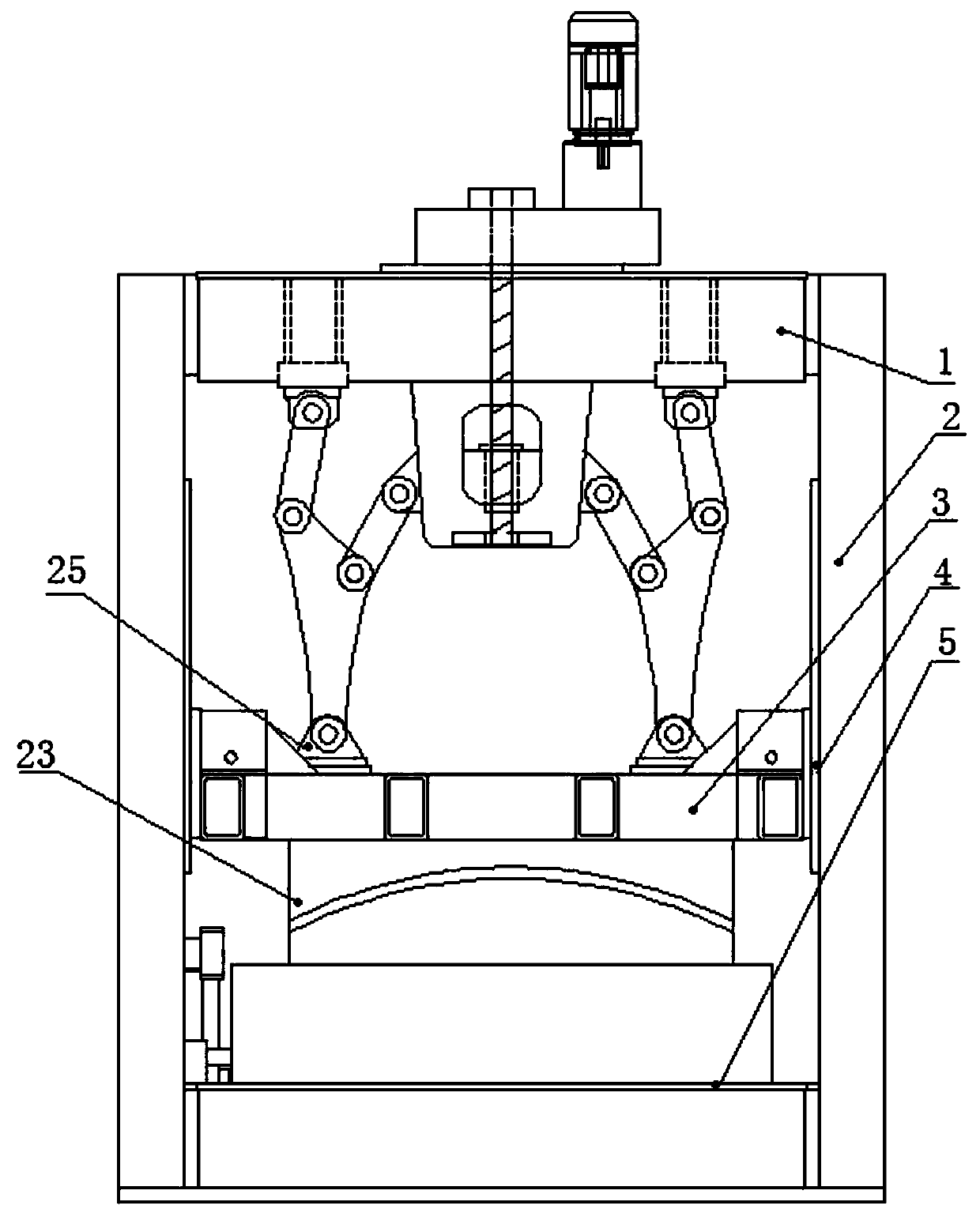

[0015] figure 1 Shown is the structural representation of the present invention.

[0016] The present invention provides a toggle mechanical hemming press, which includes a base 5, a column 2, a beam 1, a slider 3, a hemming mold 23, an overload protection device 10, a transmission mechanism and a motor reduction device.

[0017] The column 2 is vertically fixed on both sides of the base 5, the inner side of the column 2 is equipped with a guide rail 4, and the hemming mold 23 is installed at the bottom of the slide block 3;

[0018] The beam 1 is installed on the top of the column 2, the upper end of the overload protection device 10 is nested in the left and right ends of the beam 1, and the lower end is connected with the transmission mechanism.

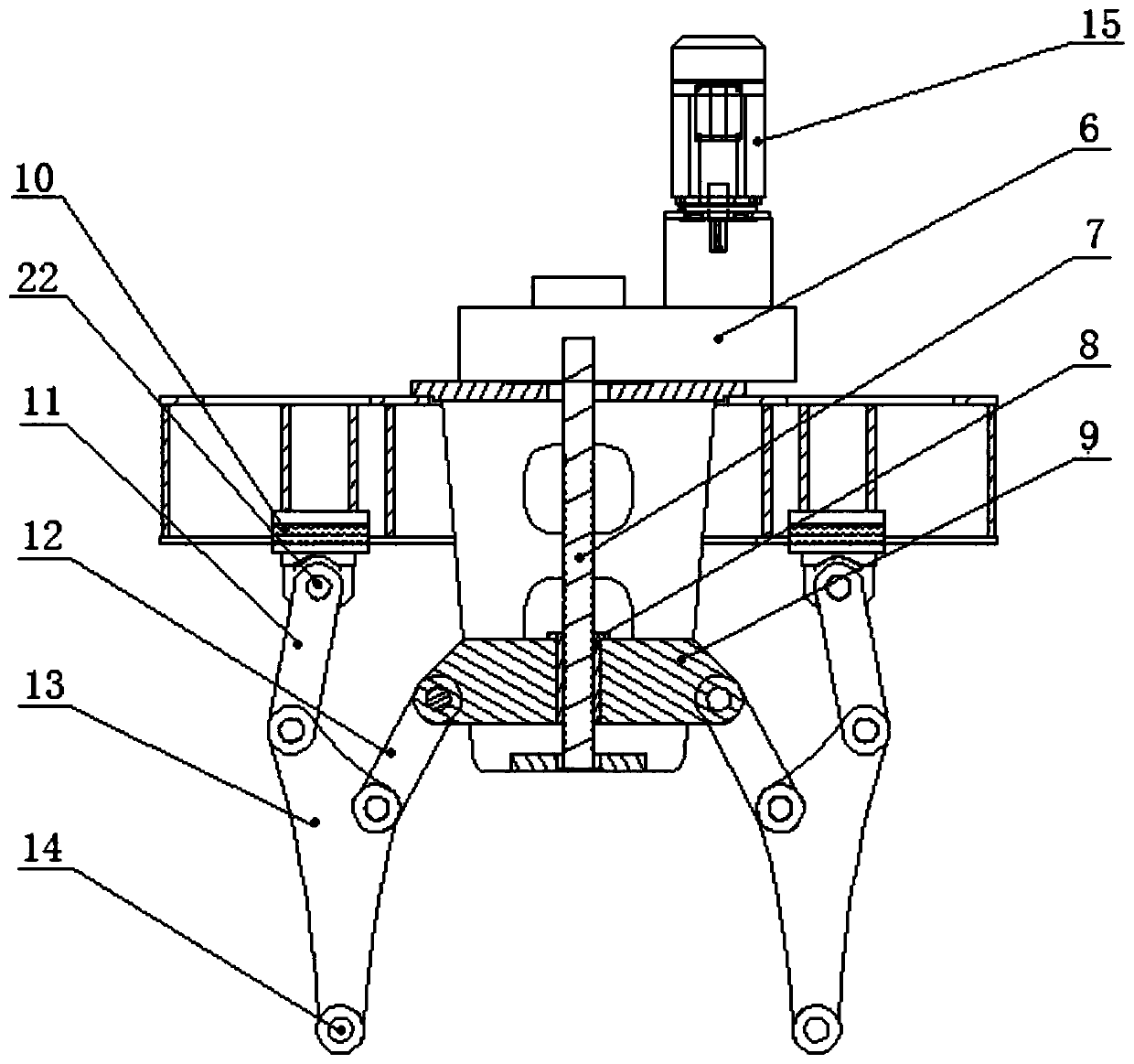

[0019] figure 2 Shown is a schematic cross-sectional view of the transmission mechanism of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com