Method and apparatus for producing nonwoven fabrics made of fibers

一种非织造织物、纤维的技术,应用在非织造布、制造工具、化学仪器和方法等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

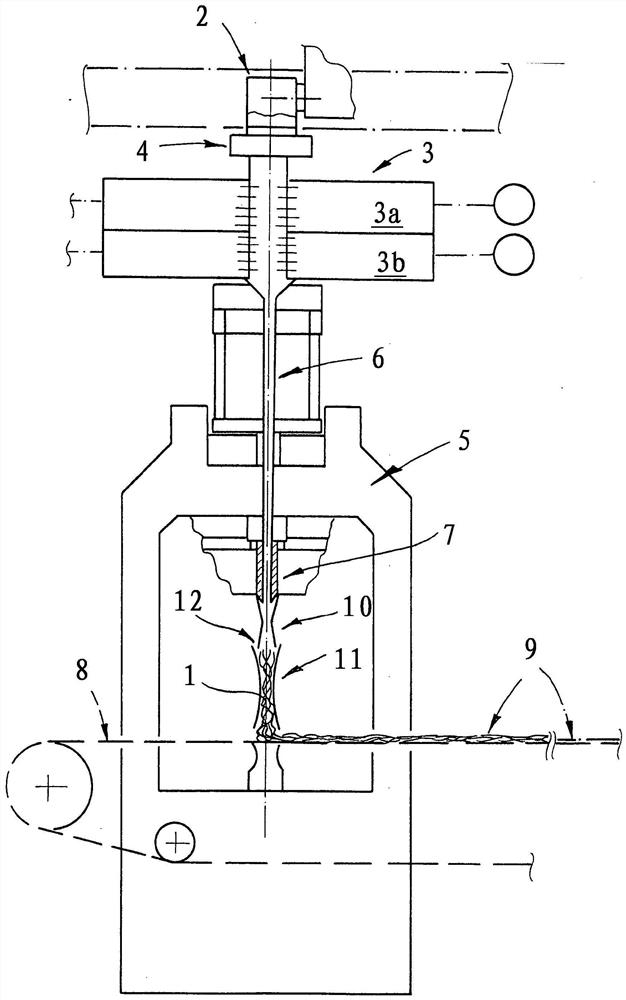

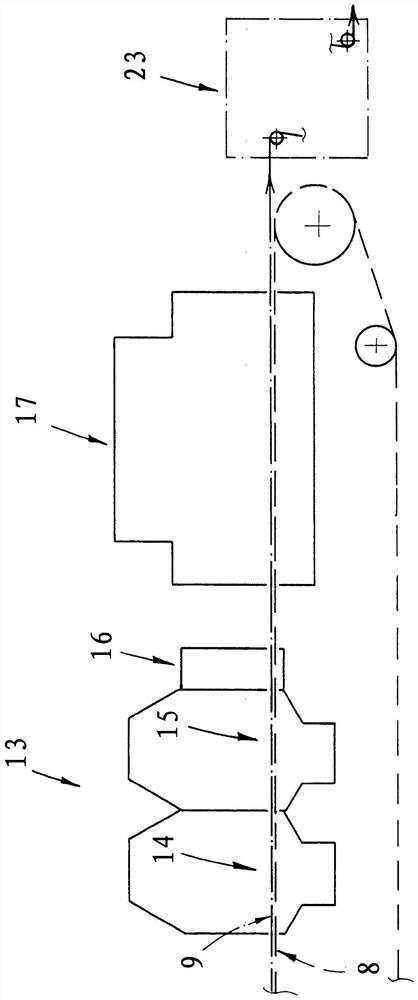

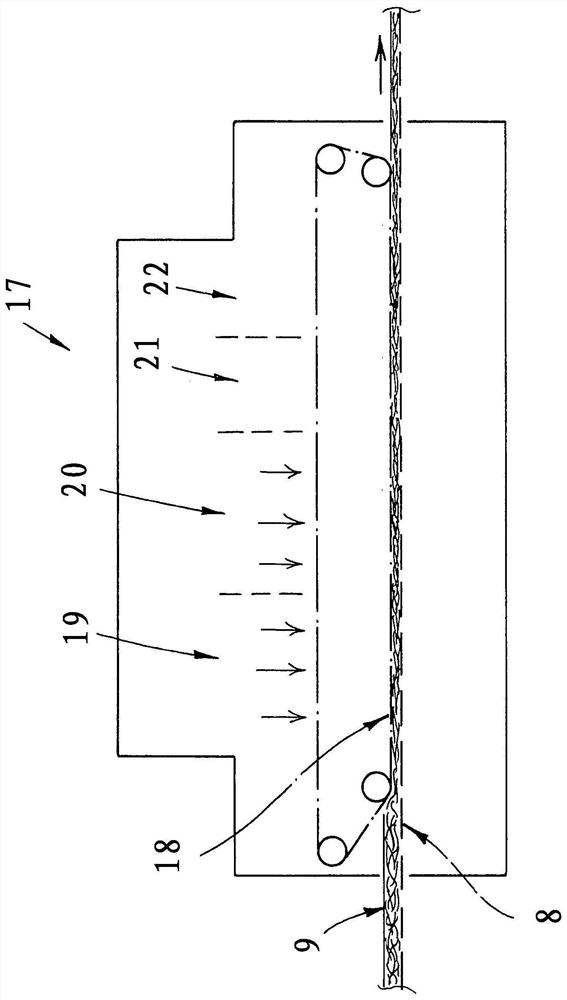

[0030] A plant according to the invention for producing a spunbond nonwoven made of continuous filaments 1 is shown in the drawing. According to a preferred embodiment of the invention, the continuous filaments 1 are produced from thermoplastics and particularly preferably from polyolefins. exist figure 1 The plant shown in is a spunbond nonwoven plant for producing a spunbond nonwoven made of continuous filaments 1 . Using the apparatus according to the invention, the continuous filaments 1 are spun out by means of a spinneret 2 and then cooled in a cooling device 3 . According to a preferred embodiment and in this example, a unit suction device 4 is provided between the spinneret 2 and the cooling device 3, which is used to suck out the spinning fumes generated in the intermediate space. Preferably and in this exemplary embodiment, the cooling device 3 has two cooling chambers 3a, 3b arranged one above the other or one after the other in the direction of flow of the filame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com