Clamping anti-shedding mechanism and socket

A technology of anti-dropping and socket, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of virtual electricity, sockets are easy to fall off, etc., and achieve the effect of improving the clamping degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

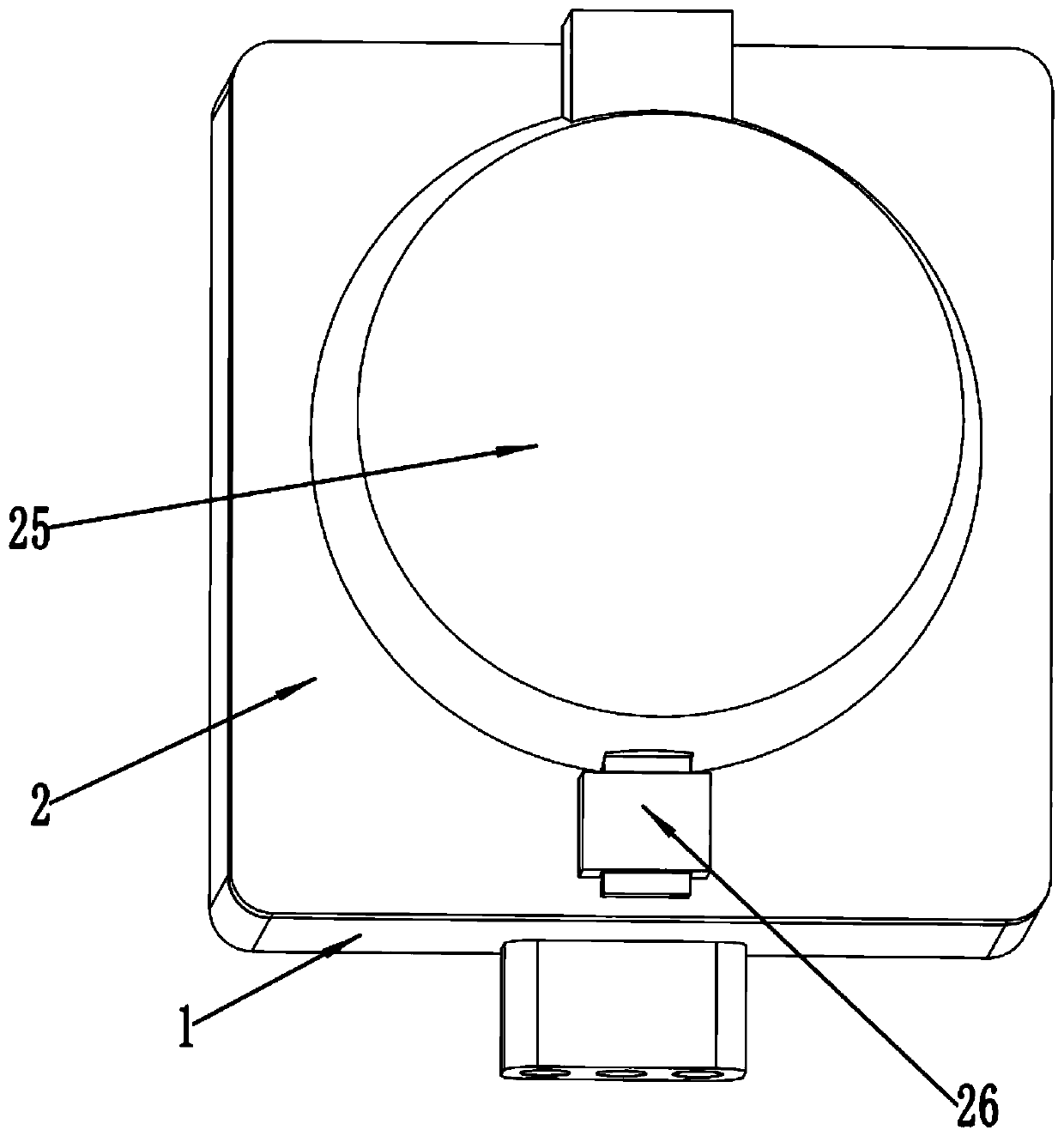

[0023] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0024] see figure Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a clamping and anti-falling mechanism includes a sliding push rod 9, a semi-arc rotating rod 10, a pressure plate 11, a compression spring 15, a jack step column 16, and a clamping column 22, and the jack step column 16 is connected with compression spring 15, is provided with inclined-plane 17 on jack step post 16 side, is provided with inclined-plane at one end of sliding push rod 9, and sliding push rod 9 inclined-planes is slidably connected with the inclined-plane 17 of described jack step post 16, slides The other end of the push rod 9 is provided with a slide push rod to push the bead 14, and the slide push rod pushes the bead 14 to be in sliding contact with the semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com