Numerical control machine tool reliability data collection and analysis system

A data acquisition and analysis, numerical control machine tool technology, applied in general control systems, control/regulation systems, digital control, etc. Complete and comprehensive scope, improved technical content, flexible data storage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

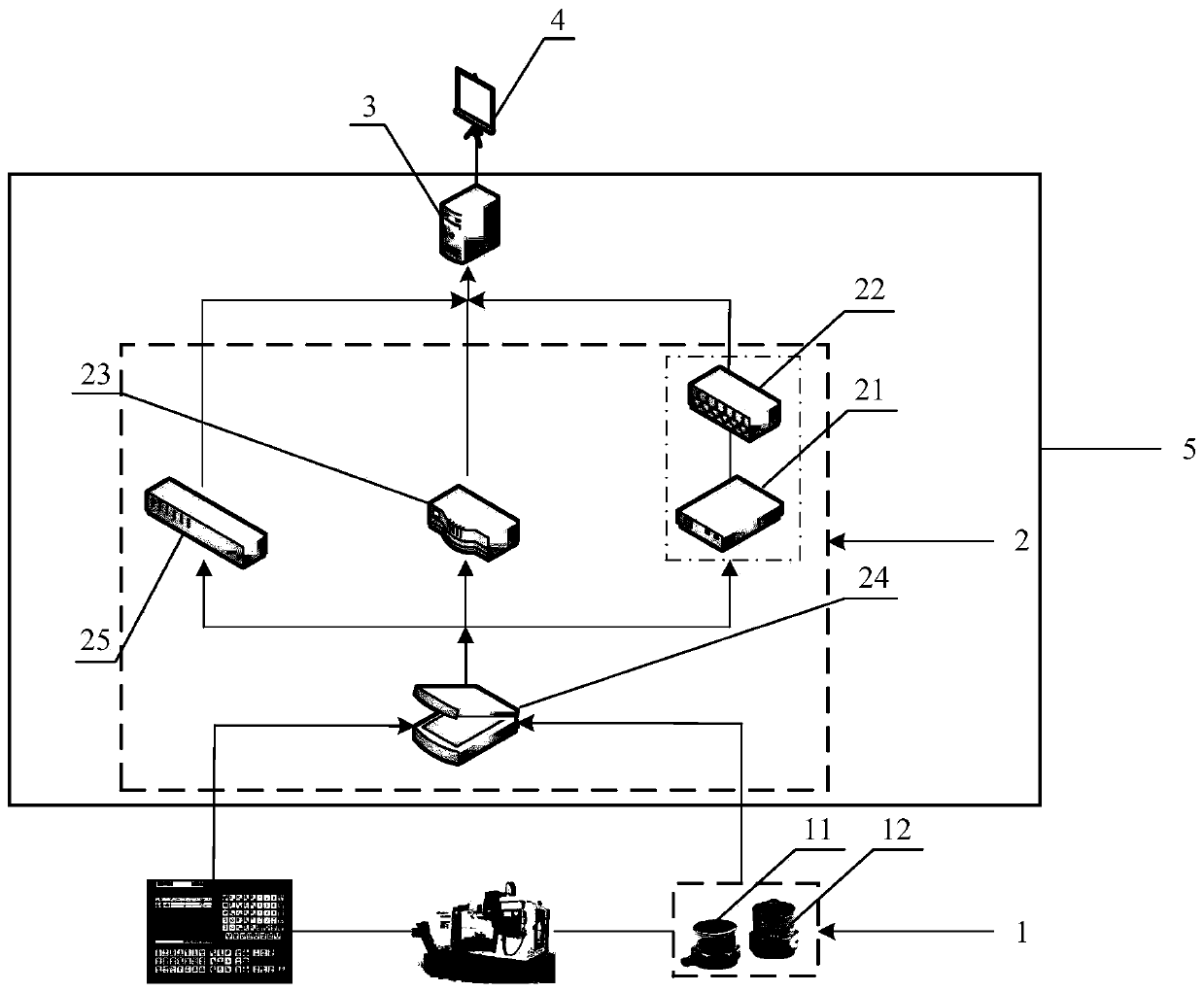

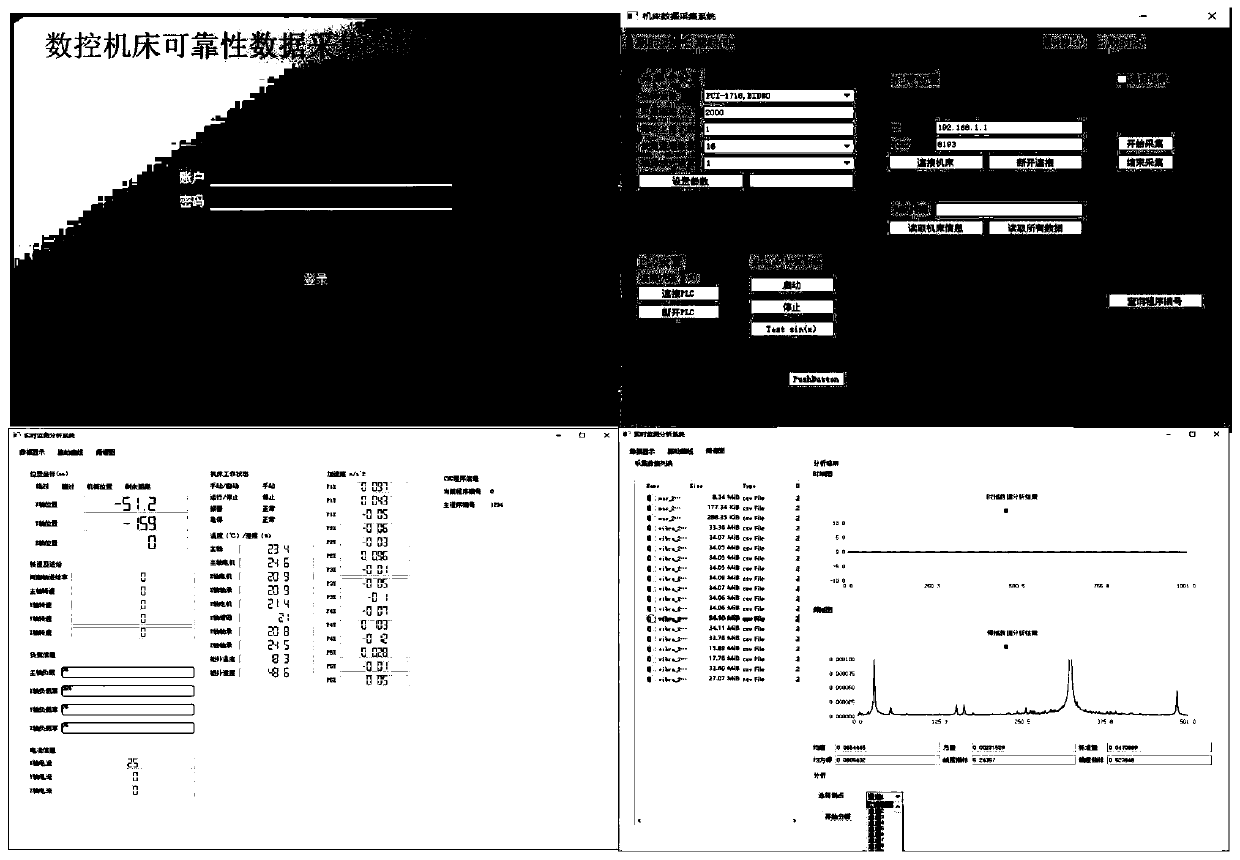

[0029] Such as figure 1 As shown, the reliability data acquisition and analysis system of a numerically controlled machine tool in the present invention mainly includes three core modules: a sensor system 1 , a data acquisition device 2 and a monitoring host computer 3 .

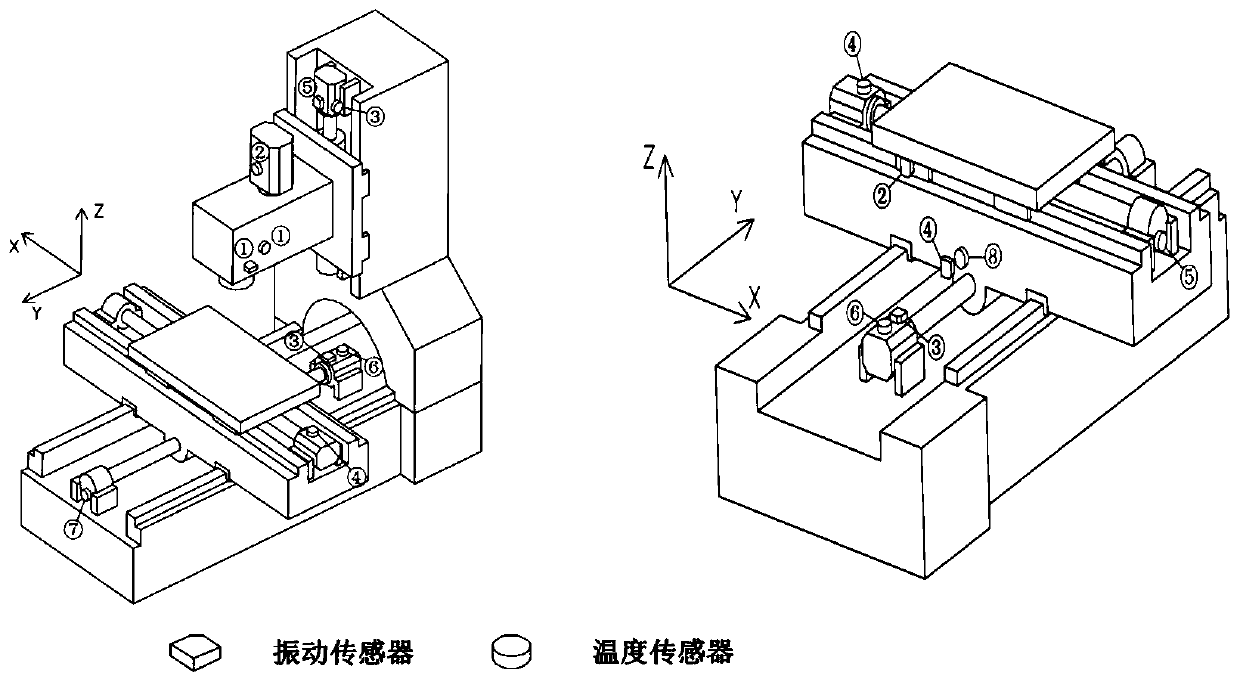

[0030] Wherein, the sensor system includes a vibration sensor 11 for monitoring vibration and a temperature sensor 12 for monitoring temperature, both of which are installed on the machine tool. The data acquisition device 2 is connected with the sensor system 1 to receive its data, and realizes the acquisition of sensor data, mainly including a signal conditioner 21 , a data acquisition card 22 , a PLC controller 23 , an AC contactor 24 and a switch 25 . The monitoring host computer 3 is a computer equipped with a windows system, which can be a desktop or a notebook computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com