Non-spherical surface-shaped swing arm type detection device and method for achieving measuring head pose self-adjustment

A detection device and aspheric surface technology, which is applied in the direction of measuring devices, electromagnetic measuring devices, and electrical devices, etc., can solve the problems of high proficiency requirements for technicians and difficulties in multi-degree-of-freedom adjustment operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following describes the detailed description in combination with specific implementation methods and accompanying drawings.

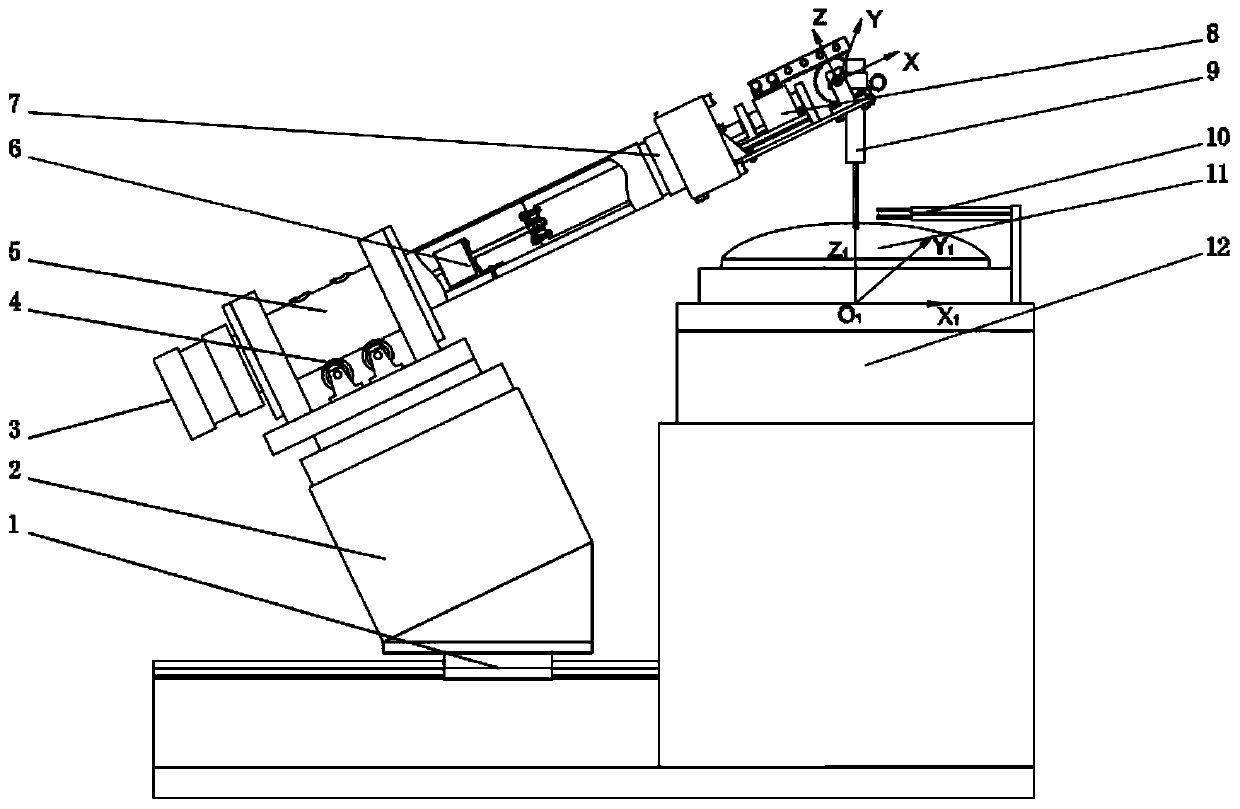

[0034] Such as figure 1 As shown in the figure, the aspheric surface swing arm type detection device that realizes the self-adjustment of the probe position and posture includes a measuring device and a dual capacitive sensor probe 10 that detects the position of the aspheric detection probe 9 . The dual-capacitance sensor probe 10 adopts the capacimetric displacement sensor of Miiridium (Beijing) Testing Technology Co., Ltd. model capaNCDT6530; the dual-capacitance sensor probe 10 is fixed on the rotating table of the processing platform 12 .

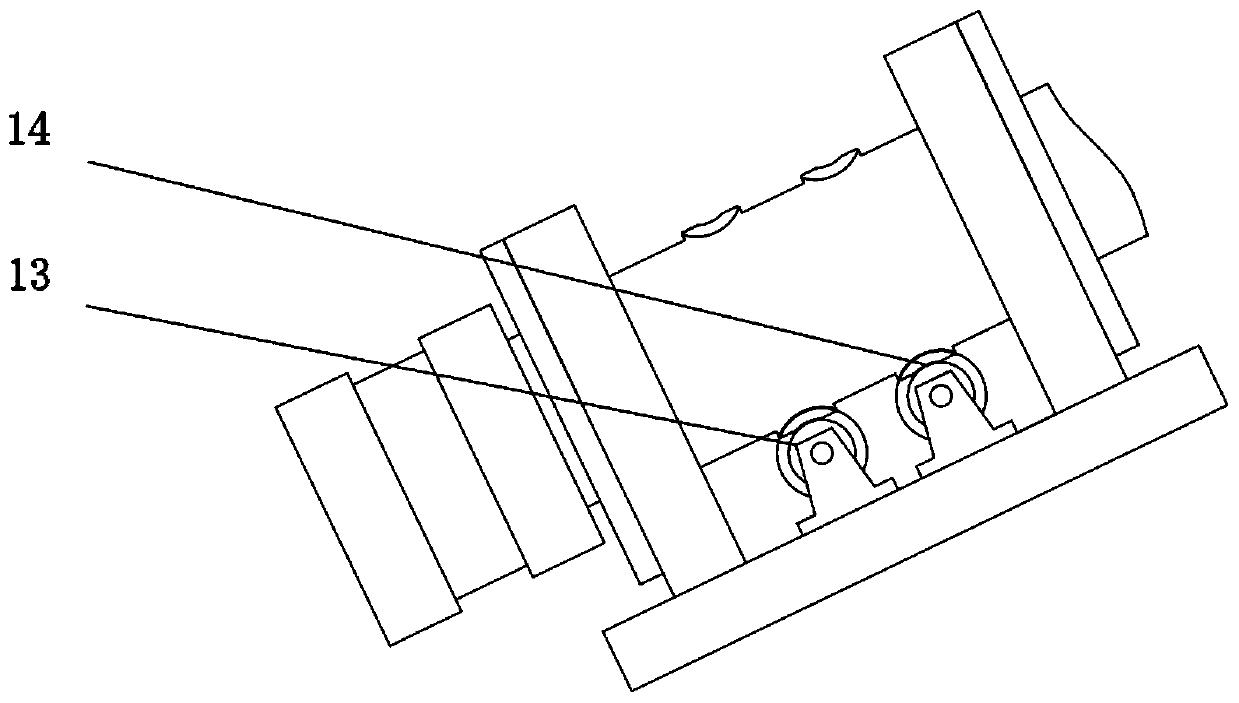

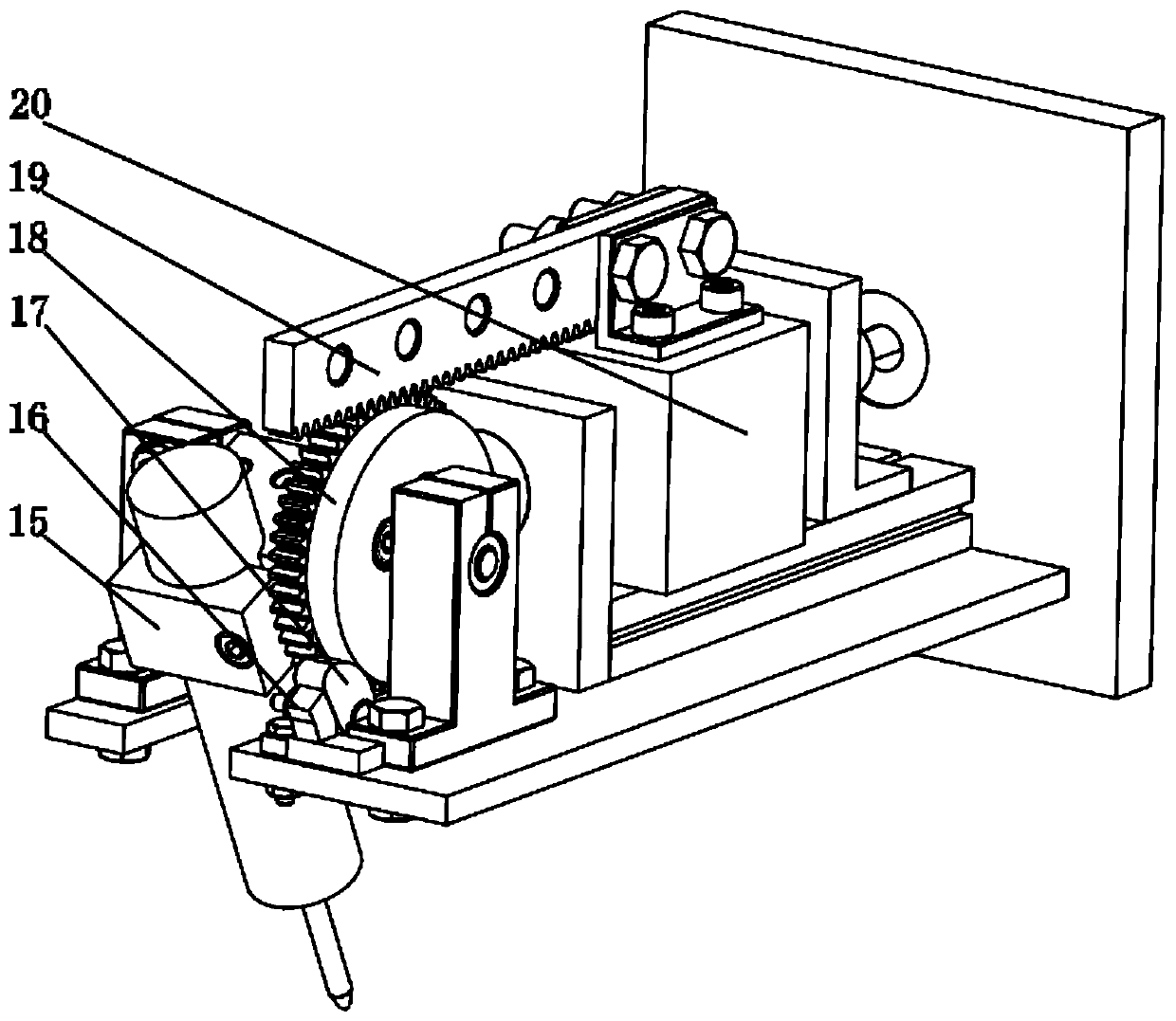

[0035] The measuring device includes a horizontal drive mechanism 1 , a swing arm rotating platform 2 , a measuring arm, a measuring head vertical adjustment device and a mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com