System for cooperatively treating garbage fly ash and leachate

A technology of co-processing and waste fly ash, which is applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of stable combustion of incinerators, etc., achieve thorough treatment effect, benefit environmental protection, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

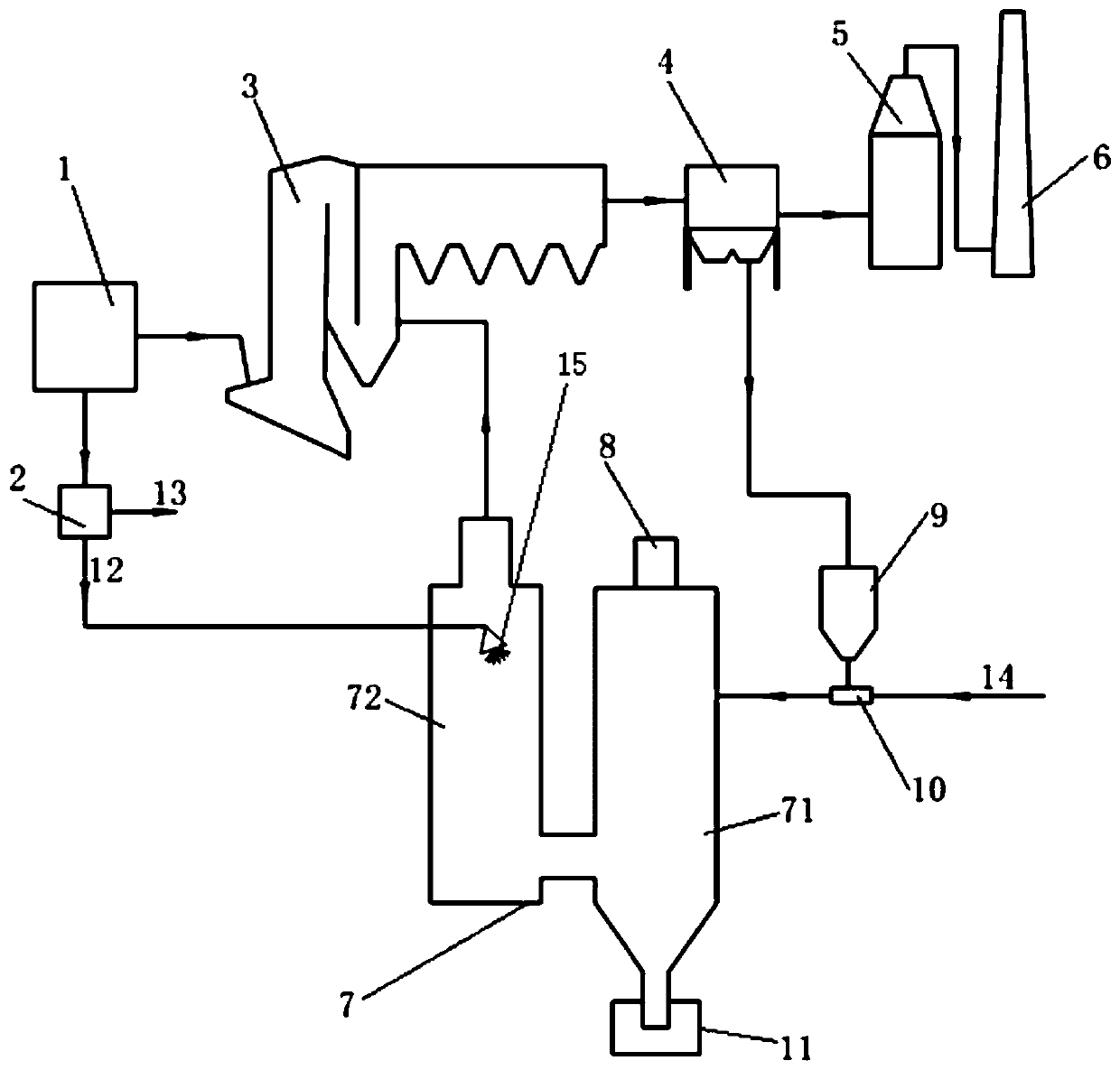

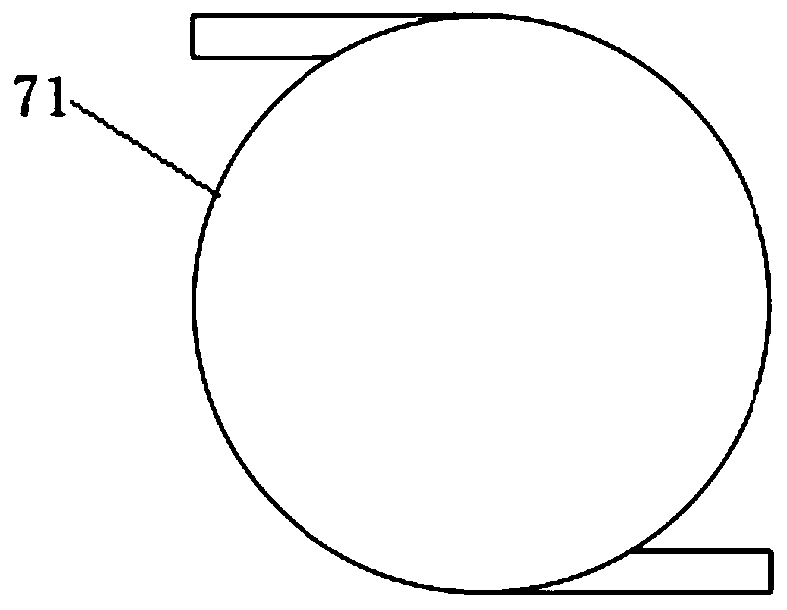

[0021] The present invention is a system for co-processing garbage fly ash and leachate, as attached figure 2 As shown, it includes garbage storage bin 1, leachate purification device 2, garbage incineration boiler 3, dust collector 4, flue gas purification device 5, chimney 6, fly ash melting furnace 7, burner 8, fly ash storage bin 9, wind Powder mixer 10 and slag pool 11. The fly ash melting furnace 7 is composed of two heat-insulating cylindrical containers, one is a melting chamber 71 and the other is an evaporation chamber 72, and the bottoms of the melting chamber 71 and the evaporation chamber 72 are connected by a flue. The outlet of the garbage storage bin 1 is respectively connected to the inlet of the leachate purification device 2 and the inlet of the garbage incineration boiler 3, the outlet of the garbage incinera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com