Micro semi-automatic ball valve

A semi-automatic, ball valve technology, used in valve details, valve devices, engine components, etc., can solve problems such as dependence and short service life, and achieve the effects of sensitive response, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

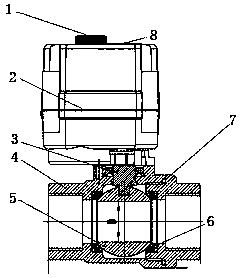

[0008] A miniature semi-automatic ball valve, the ball valve includes a handwheel 1, an actuator 2, a valve stem 3, a valve body 4, a ball core 5, a valve seat 6, a sealing ring 7 and an observation window 8, and the valve body 4 is set On the top of the ball valve, the valve body 4 includes symmetrical inlets and outlets, the valve seat 6 is arranged in the middle of the valve body 4, the ball core is installed on the valve seat 6, and the valve stem 3 is vertically arranged in the valve body 4, one end of the valve stem 3 is connected to the ball core 5, and the other end is connected to the output shaft of the actuator 2, and the actuator 2 is arranged on the upper part of the valve body 4. The hand wheel 1 is connected to the upper part of the actuator 2, the top of the actuator 2 is provided with a plurality of observation windows 8, and the valve body 4 is provided with a sealing ring 7.

[0009] The above embodiments are only used to illustrate the present invention rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com