Comprehensive stern pipe sealing lubricating oil system

A lubricating oil system, a comprehensive technology, applied in engine sealing, propulsion components, ship construction, etc., can solve the problems that sealing rings cannot withstand seawater pressure, seawater backflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

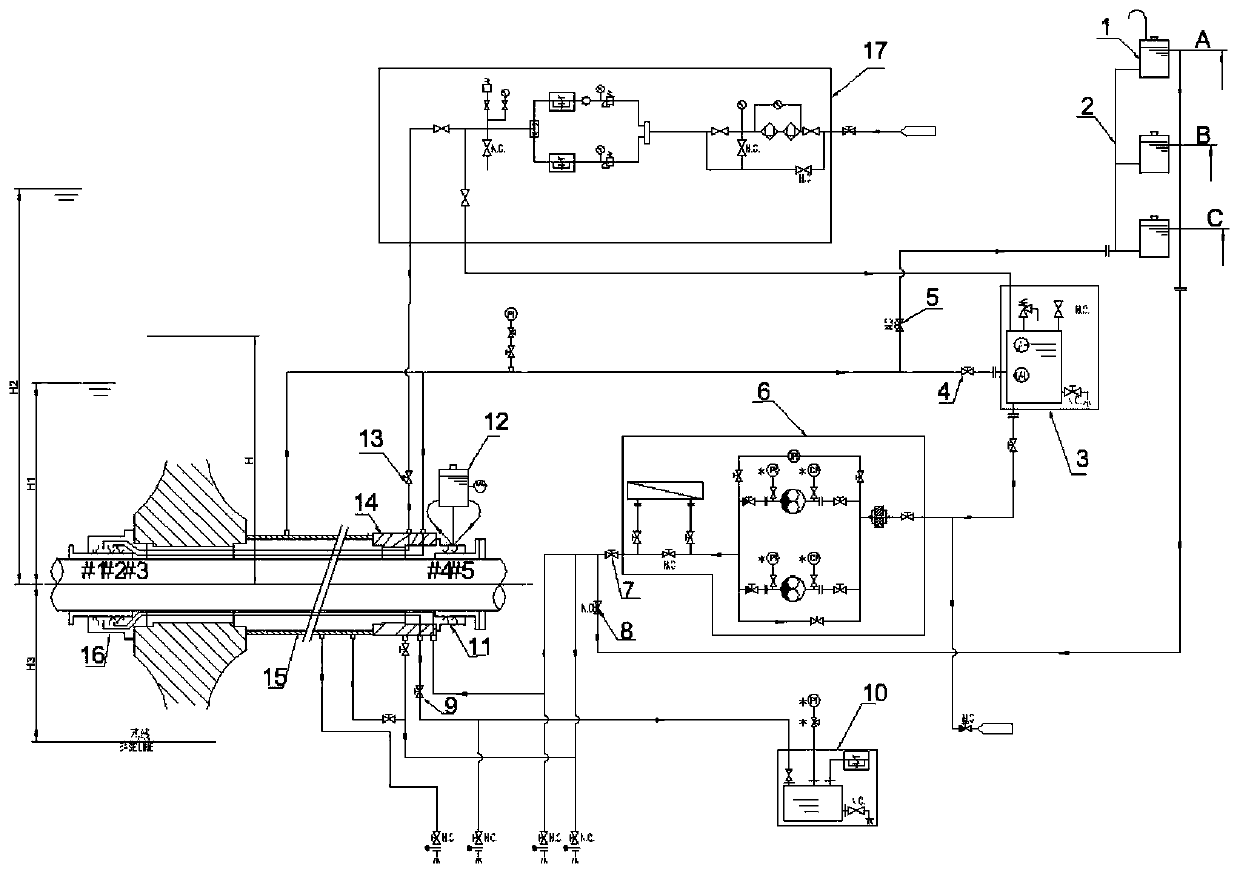

[0036] Such as figure 1 As shown, for a 308,000-ton crude oil carrier, the height of the centerline of the stern shaft from the hull baseline is H3=5.5 meters, the height of the full load from the center line of the stern shaft is H2=16.95 meters, and the height of the ship’s ballast water from the center line of the stern shaft is H1= 5.2 meters, H2-H1≥8m. The stern tube 15 is connected with an air supply unit 17, a lubricating oil circulation tank 3, a forced circulation pump unit 6, a stern sealing oil tank 12, and a discharge collection unit 10 through a hose 2, forming a complete stern tube air-sealed lubricating oil system. The stern pipe, the lubricating oil circulation cabinet and the forced circulation pump set form the first circulation network, the outlet of the first circulation network is provided with a fourth normally open stop valve 4, and the loop of the first circulation network is provided with a third normally open stop valve 7. The stern tube has a front ...

Embodiment 2

[0040] Such as figure 1 As shown, for a 308,000-ton crude oil carrier, the height of the centerline of the stern shaft from the hull baseline is H3=4.5 meters, the height of the full load from the center line of the stern shaft is H2=12.8 meters, and the height of the ship’s ballast water from the center line of the stern shaft is H1= 5.2 meters, H2-H1<8m. The stern tube 15 is connected with an air supply unit 17, a lubricating oil circulation tank 3, a forced circulation pump unit 6, a stern sealing oil tank 12, and a discharge collection unit 10 through a hose 2, forming a complete stern tube air-sealed lubricating oil system. The stern pipe, the lubricating oil circulation cabinet and the forced circulation pump set form the first circulation network, the outlet of the first circulation network is provided with a fourth normally open stop valve 4, and the loop of the first circulation network is provided with a third normally open stop valve 7. The stern tube has a front c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com