Turbine drilling type multi-branch slim hole well completion tool and operation method

A turbo-drilling and multi-branch technology, which is applied in wellbore/well components, drilling equipment and methods, and driving devices for drilling in wellbore, etc. problems, to achieve the effects of simple and reliable construction operations, increased oil well production, and large processing radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are provided in conjunction with the accompanying drawings.

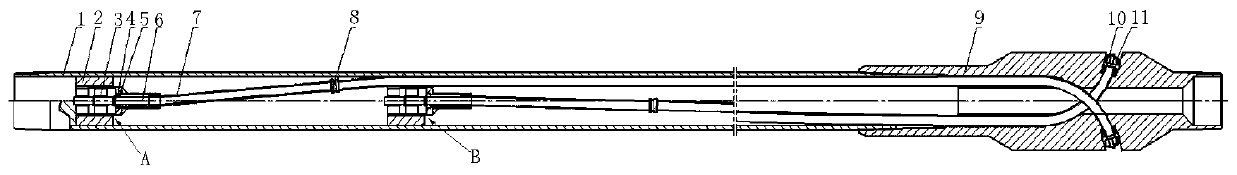

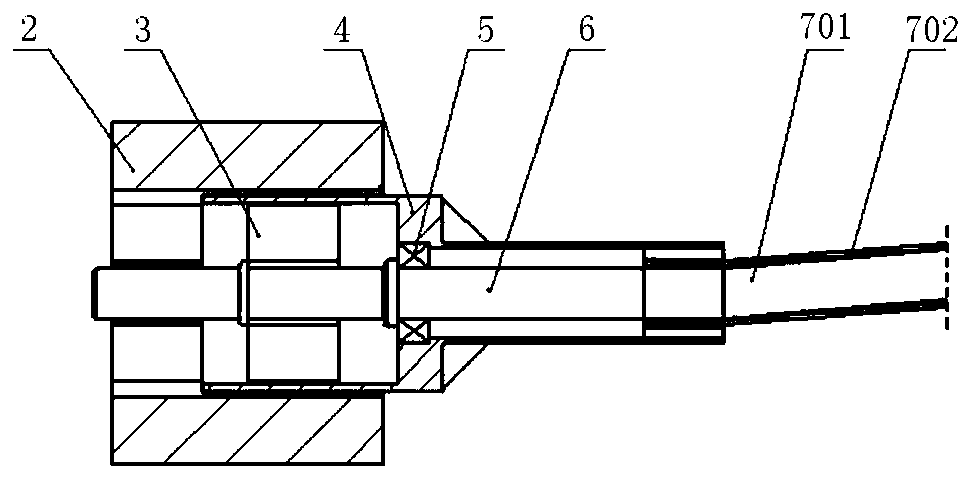

[0026] Such as figure 1 and figure 2 As shown, the turbodrilling multi-branch slimhole completion tool of the present invention includes an outer casing 1, a diverter 9 is connected to the lower part of the outer casing 1, and two pipeline outlets are symmetrically arranged on the side wall of the diverter 9. The outer casing 1 is provided with an upper turbine A and a lower turbine B, and the upper turbine A and the lower turbine B both include a turbine stator 2, a turbine support seat 4, a turbine rotor 3 and a rotating mandrel that are sequentially arranged from outside to inside 6. The lower ends of the upper turbine A and the lower turbine B are connected to pipelines 7, and the lower ends of each pipeline 7 are connected to branch dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com