Scaffold movement platform base

A mobile platform and scaffolding technology, applied in the field of scaffolding, can solve the problems of excessive arrangement, high construction cost, and hidden dangers in erection volume inspection, and achieve the effects of small erection volume, improved construction efficiency, and convenient uncontrollable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in combination with specific embodiments.

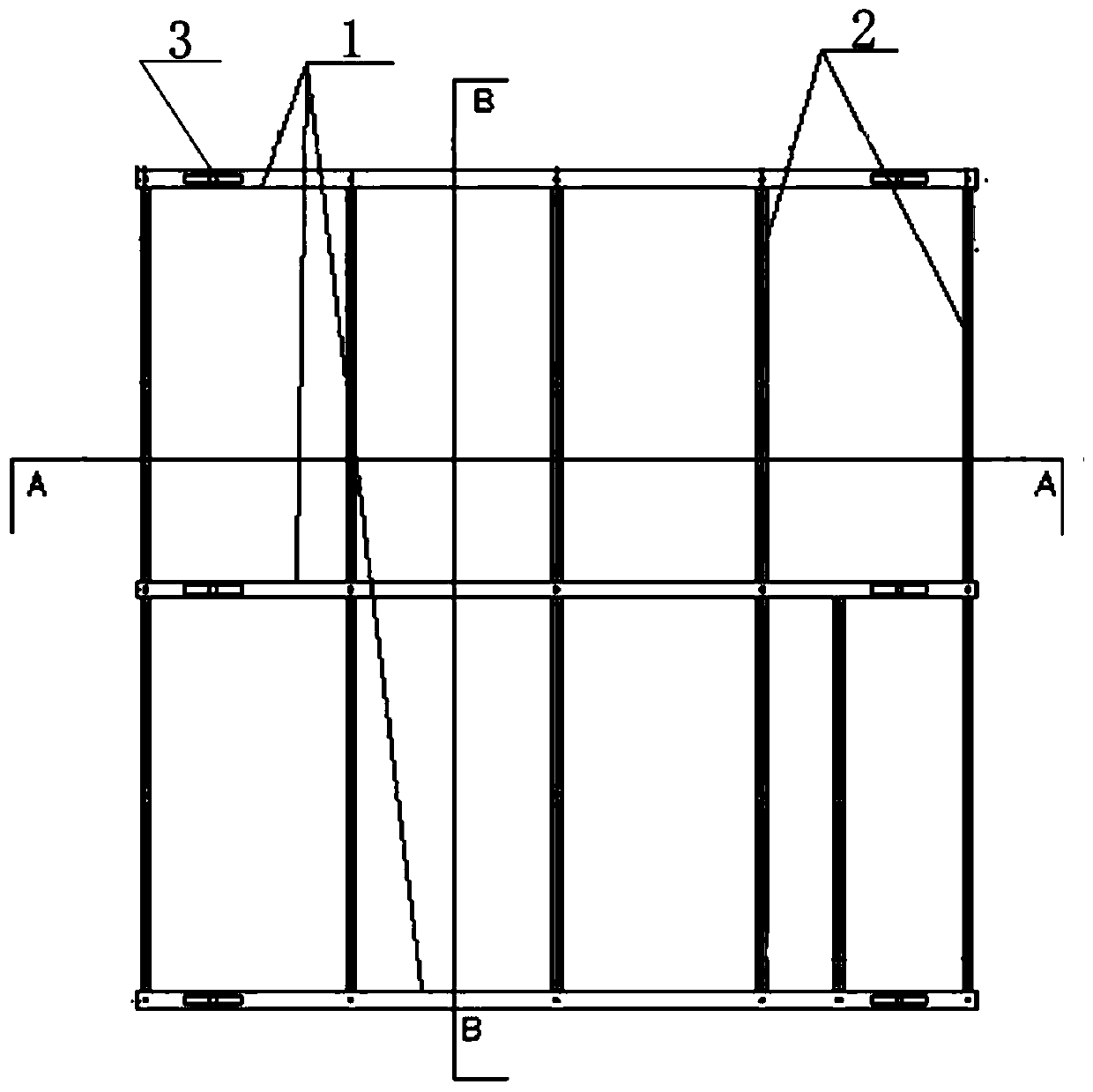

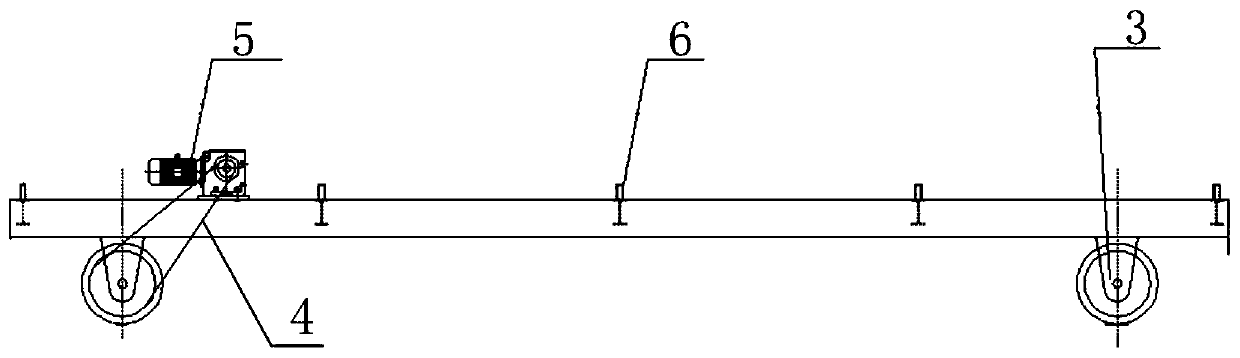

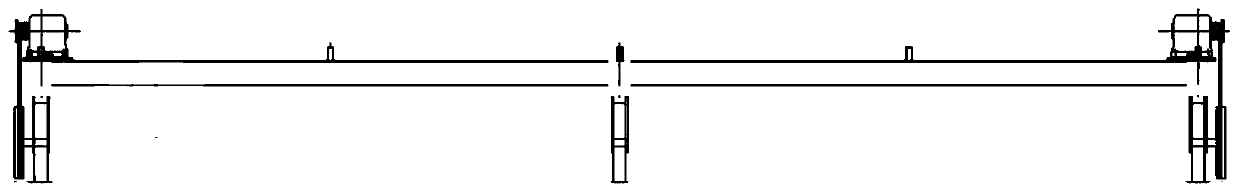

[0021] Such as Figure 1 to Figure 3 As shown, a scaffold mobile platform base of the present invention includes a main beam 1, a secondary beam 2 and a walking wheel 3, three main beams 1 are arranged in parallel and spaced apart, and five secondary beams 2 are welded on the main beam 1 at intervals, and the secondary beams 2 Set vertically with the main beam 1, the main beam 1 and the secondary beam 2 are combined to form a closed frame structure; the traveling wheel 3 is arranged at the bottom of the main beam 1, and the driving wheel of the traveling wheel 3 communicates with the drive motor through the transmission chain 4 5 are connected; the main beam 1 is a rectangular tube, and the secondary beam 2 is an I-beam; the traveling wheels 3 are located at the ends of the main beam; the traveling wheels 3 are solid rubber tires; the secondary beam 2. There are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com