Clarifying method for removing starch in sugar making process

A starch and amylase technology, which is applied in sugar production, sugar juice purification, sucrose production, etc., can solve problems such as amylase residues and affecting the stability of downstream products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

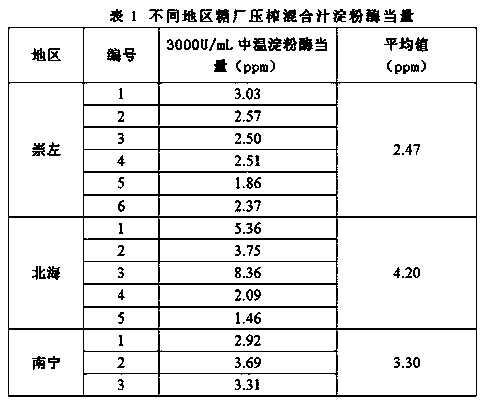

Embodiment 1

[0016] Example 1, the clarification method for removing starch in the sugar making process is carried out according to the following steps: the first step, pre-ashing, adding phosphoric acid and milk of lime to the squeezed mixed juice for pre-ashing, to obtain primary cane juice; the second step , primary heating, heating the primary sugarcane juice to gelatinize the starch in the primary sugarcane juice to obtain the secondary sugarcane juice; the third step, the main ash, further ash the secondary sugarcane juice to obtain the third sugarcane juice; the fourth step , amylase degrades starch, and stays three times of cane juice in a reaction box with a temperature of 60°C to 75°C for 20min to 60min to obtain four times of sugarcane juice; the fifth step, second heating, heats four times of sugarcane juice to inactivate Amylase. The squeezed mixed juice is the existing known and common sugarcane squeezed mixed juice. In the fourth step, the third sugarcane juice stays in a r...

Embodiment 2

[0017] Example 2, the clarification method for removing starch in the sugar making process is carried out according to the following steps: the first step, pre-ashing, adding phosphoric acid and milk of lime to the squeezed mixed juice for pre-ashing, to obtain primary sugarcane juice; the second step , primary heating, heating the primary sugarcane juice to gelatinize the starch in the primary sugarcane juice to obtain the secondary sugarcane juice; the third step, the main ash, further ash the secondary sugarcane juice to obtain the third sugarcane juice; the fourth step , amylase degrades starch, and stays three times of cane juice in a reaction box with a temperature of 60°C or 75°C for 20 minutes or 60 minutes to obtain four times of sugarcane juice; the fifth step, second heating, heats four times of sugarcane juice to inactivate Amylase.

Embodiment 3

[0018] Example 3, as an optimization of the above example, in the first step, the amount of phosphoric acid added is 150ppm to 600ppm of the total phosphoric acid value of the cane juice after phosphoric acid is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com