Sludge drying carbonization drying furnace heating control system

A sludge drying and control system technology, applied in fixed carbonization furnaces, dehydration/drying/thickened sludge treatment, chemical instruments and methods, etc. The problem of heat loss in the furnace and carbonization furnace can be solved to achieve the effect of controlling pollution, reducing production costs and reducing exhaust gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

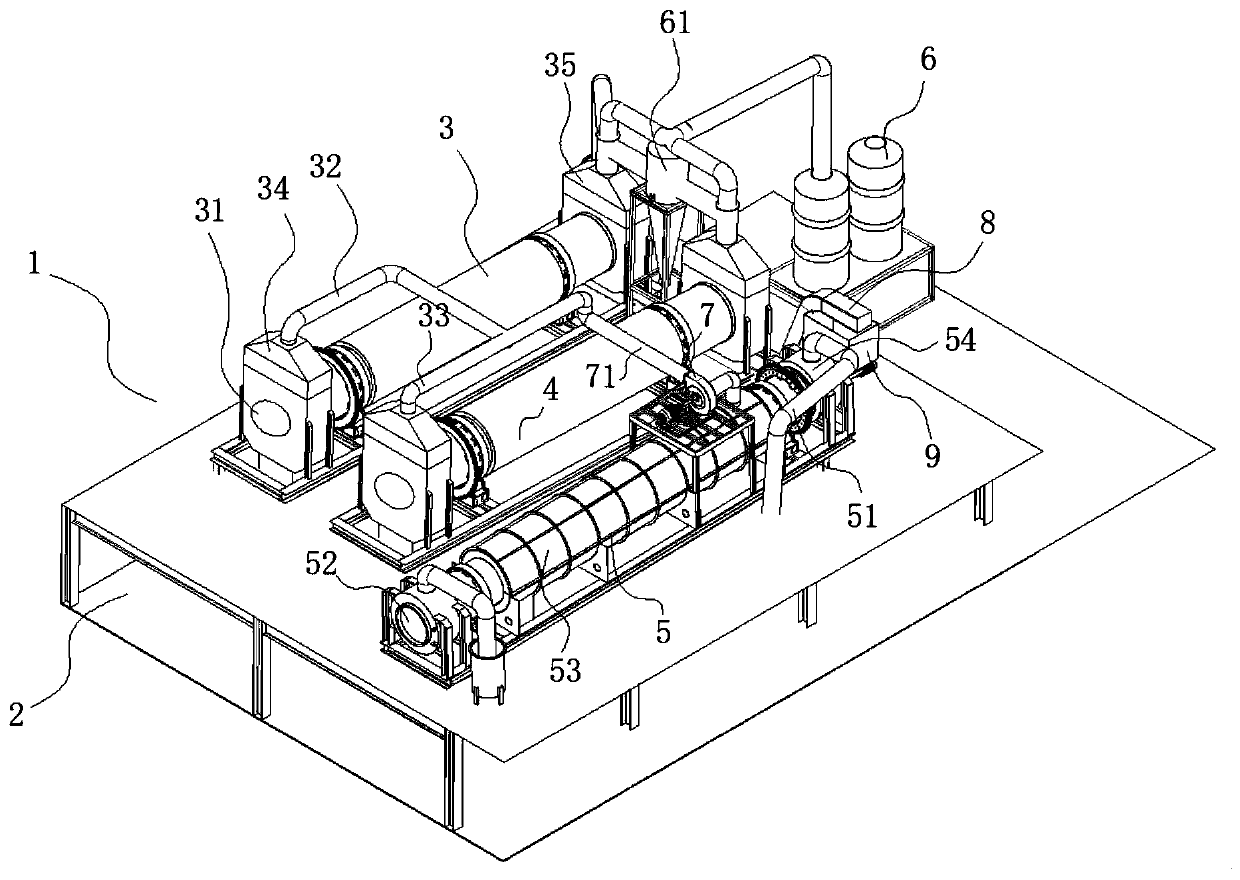

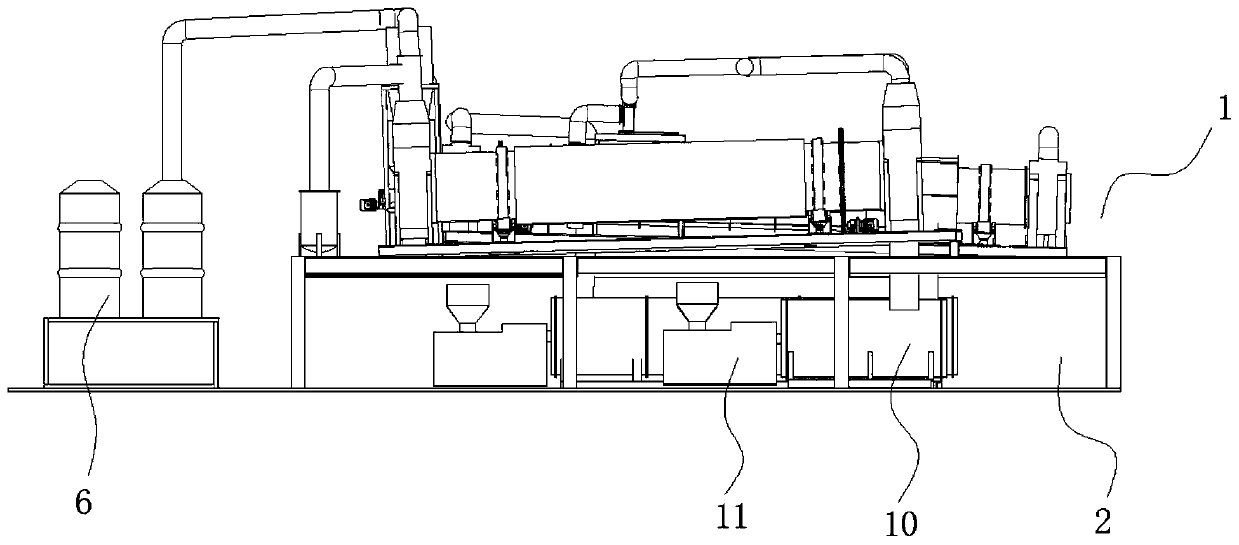

[0025] Such as Figure 1-2 The heat supply control system for sludge drying and carbonization drying furnace shown in the figure includes a treatment system 1 and a heating system 2 arranged in upper and lower layers. Through layered settings, the space utilization rate can be effectively improved and land resources can be saved. The treatment system 1 includes a first drying furnace 3 , a second drying furnace 4 and a carbonization furnace 5 , and the heating system 2 includes a second combustion chamber 10 and a biomass burner 11 .

[0026] The first drying furnace 3 and the second drying furnace 4 are arranged side by side, and are communicated with a pipeline for internal circulation of hot gas at their respective feeding bins 34 ports. The pipeline branch line 1 32 on the carbonization furnace 5 is connected to the pipeline branch line 2 33 on the drying furnace 2 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com