A kind of preparation method of ZSM-48 molecular sieve with low silicon aluminum ratio

A low-silicon-aluminum ratio, molecular sieve technology, applied in the direction of molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of expensive template agents, long crystallization time, etc., to shorten the crystallization time, improve Effects of heterogeneous selectivity, high application value and prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

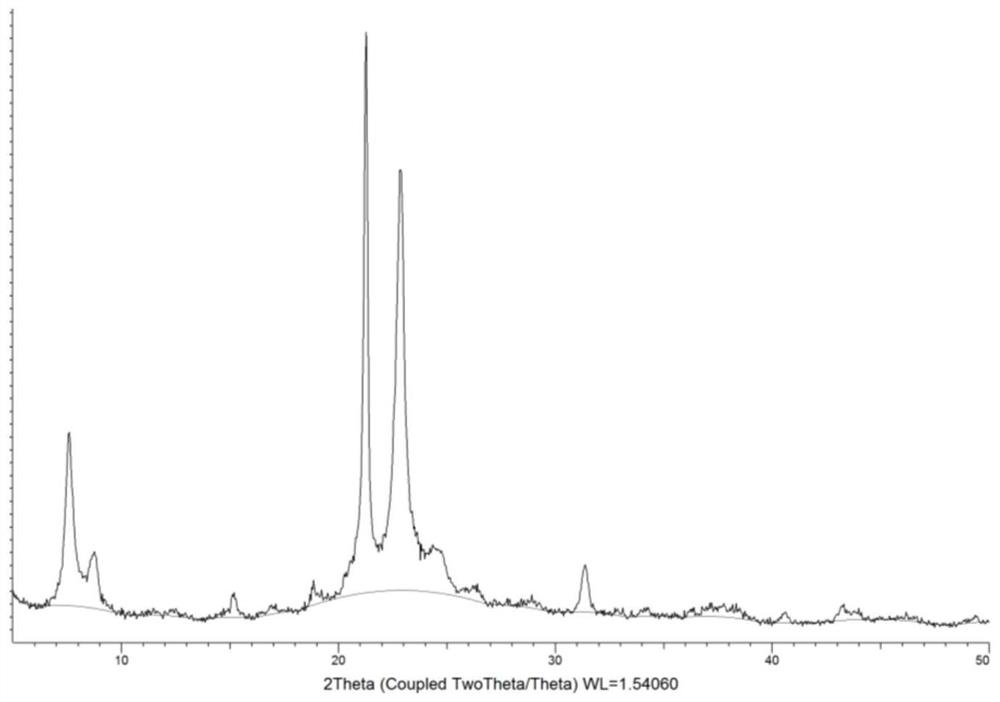

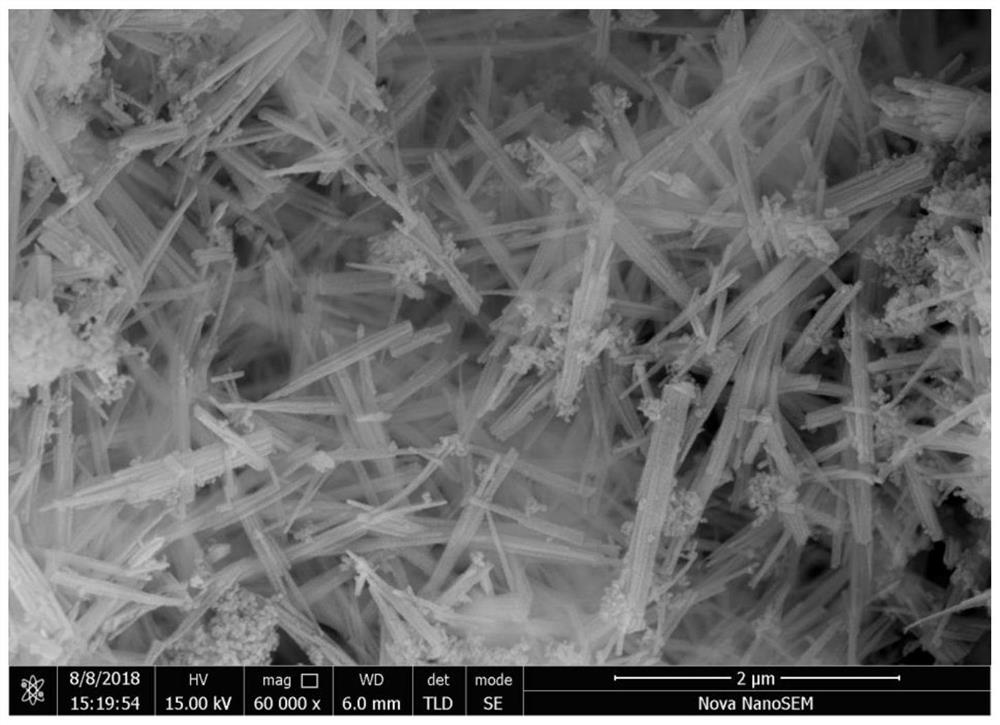

Embodiment 1

[0063] Weigh 2.72g of aluminum sulfate and 0.1g of sodium hydroxide, add to 30g of deionized water, stir well, add dropwise a solution of 2.1g of tetraethylammonium hydroxide, 1.3g of cyclohexylamine and 3.6g of deionized water, Stir for 1 hour, add 18 g of silica sol (solid content 41%) dropwise, stir for 2 hours to obtain a sol, transfer the mixed sol to a pressure melting bomb with a polytetrafluoroethylene liner, rotate at a speed of 10 rpm, and crystallize for 48 hours, the crystallization temperature was 140°C, and it was roasted at 550°C for 8 hours. The obtained crystallized product was analyzed by XDR to be ZSM-48 molecular sieve with a relative crystallinity of 98%.

[0064] SiO 2 / Al 2 o 3 = 30;

[0065] Templating agent / SiO 2 = 0.2;

[0066] Na 2 O / SiO 2 =0.01;

[0067] h 2 O / SiO 2 =20;

Embodiment 2

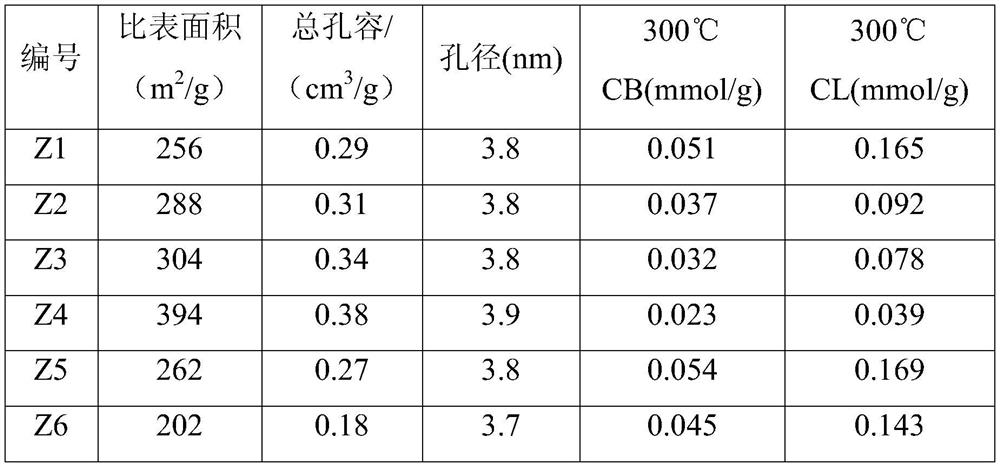

[0069] Weigh 0.49g of sodium aluminate and 0.48g of sodium hydroxide, add them to 150g of deionized water, stir evenly, add dropwise a solution of 0.25g of hexamethylammonium chloride, 5.4g of dimethylamine and 12g of deionized water, and stir for 1 hour , add 18g of white carbon black drop by drop, stir for 2 hours to obtain a sol, transfer the mixed sol to a PTFE-lined pressure melting bomb, rotate at a speed of 20 rpm, crystallize for 60 hours, and the crystallization temperature is 150°C , roasted at 560°C for 8 hours, and the obtained crystallized product was analyzed by XDR to be ZSM-48 molecular sieve, with a relative crystallinity of 99%, code Z2, and the properties of the product are shown in Table 1.

[0070] SiO 2 / Al 2 o 3 = 50;

[0071] Templating agent / SiO 2 =0.4;

[0072] Na 2 O / SiO 2 =0.02;

[0073] h 2 O / SiO 2 = 30;

Embodiment 3

[0075] Weigh 0.32g of aluminum nitrate and 1.0g of potassium hydroxide, add to 50g of deionized water, stir evenly, add dropwise a solution of 0.2g of hexamethylammonium bromide, 77.5g of di-n-propylamine and 12.3g of deionized water, and stir for 1 hour , add 18g tetraethyl orthosilicate dropwise, stir for 2h to get the sol, transfer the mixed sol to the pressure melting bomb lined with polytetrafluoroethylene, rotate at a speed of 30 rpm, crystallize for 60 hours, and the crystallization temperature is Calcined at 160°C and 570°C for 8 hours, the obtained crystallized product was analyzed by XDR to be ZSM-48 molecular sieve, with a relative crystallinity of 100%, code number Z3, and the properties of the product are shown in Table 1.

[0076] SiO 2 / Al 2 o 3 = 101;

[0077] Templating agent / SiO 2 = 2.5;

[0078] Na 2 O / SiO 2 = 0.1;

[0079] h 2 O / SiO 2 =40

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com