Low-pressure cantilever casting production line

A casting production line and low-pressure casting technology, which is applied in the field of low-pressure cantilever casting production line, can solve the problems of low production efficiency and difficulty in automatic production, and achieve the effects of improving production efficiency, solving relatively poor compactness, and realizing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

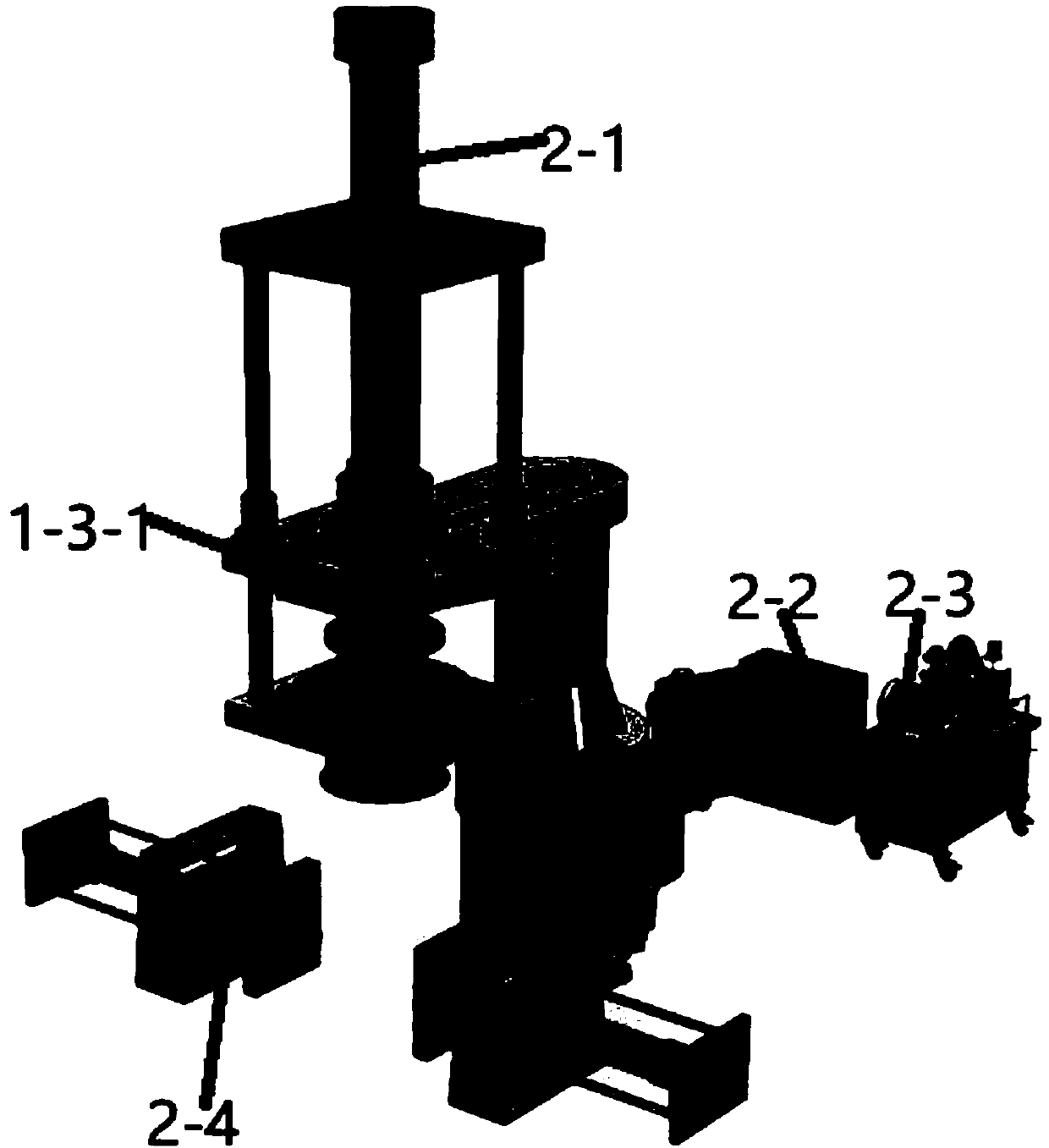

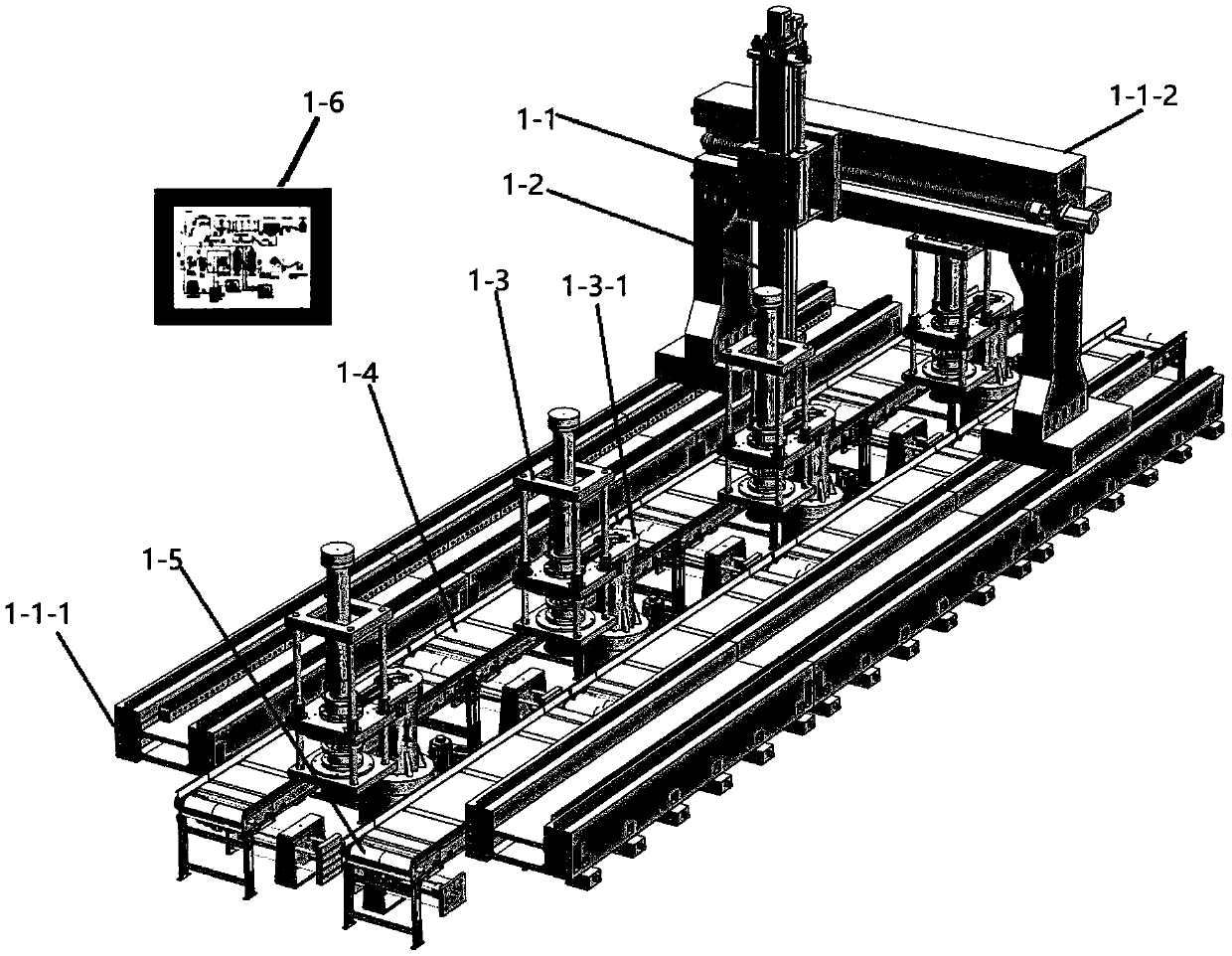

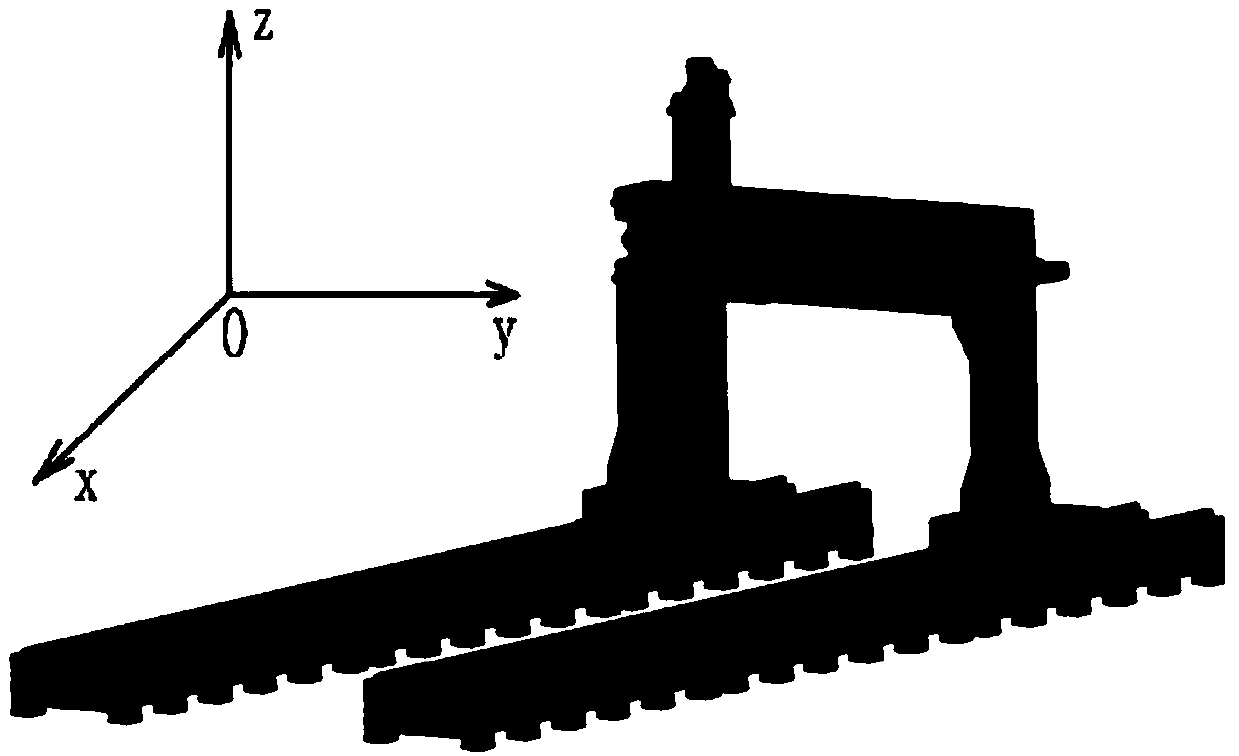

[0022] like figure 2 As shown, the low-pressure cantilever casting production line of the present invention includes a low-pressure casting gantry equipment (1-1), a sand core grabbing manipulator (1-2), a casting unit (1-3), a low-pressure cantilever casting machine (1-3- 1) The feeding conveyor belt (1-4), the finished product conveyor belt (1-5), and the low-pressure casting gantry foundation guide rail (1-1-1) is placed on the ground. The casting unit (1-3) is located at the inner central axis of the low-pressure casting gantry foundation guide rail (1-1-1), and the placement depth is 0.5m. The feeding conveyor belt (1-4) and the finished product conveyor belt (1-5) are located on both sides of the casting unit (1-3) with a placement depth of 0.5m. The low-pressure casting production line consists of a linear array of four castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com