A kind of composite polyamide membrane with salt concentration responsiveness and preparation method and use thereof

A composite polyamide membrane and polyamide membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve high-efficiency separation and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Composite polyamide membranes were prepared as follows:

[0029] 1. Fix the asymmetric polysulfone ultrafiltration membrane (used as a support layer) on a glass plate and a Teflon frame, then pour the aqueous phase monomer solution into the Teflon frame, and soak the support layer for 1-10 minutes;

[0030] 2. Pour off the aqueous monomer solution, and use high-pressure gas to dry the surface moisture of the support layer (or use a rubber roller to remove moisture). Then pour the oil phase monomer solution into the surface of the support layer, and the interfacial polymerization reaction takes 30-600s;

[0031] 3. Pour off the oil phase monomer solution, and store the prepared composite polyamide membrane in distilled water at 4°C.

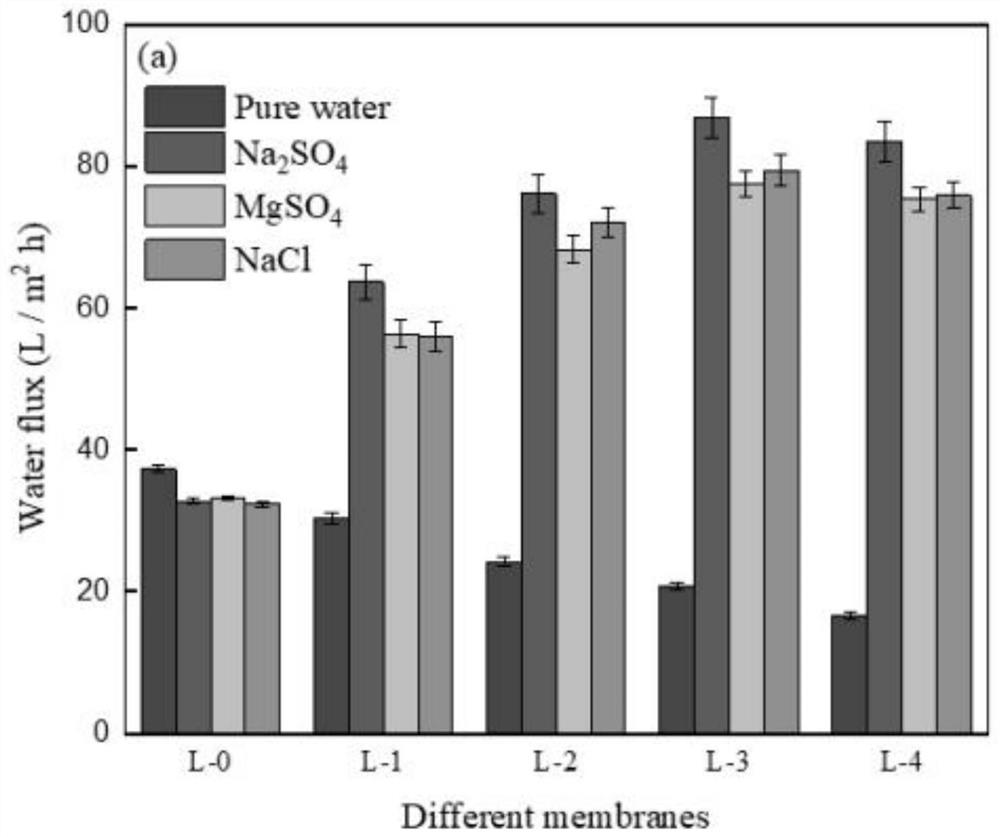

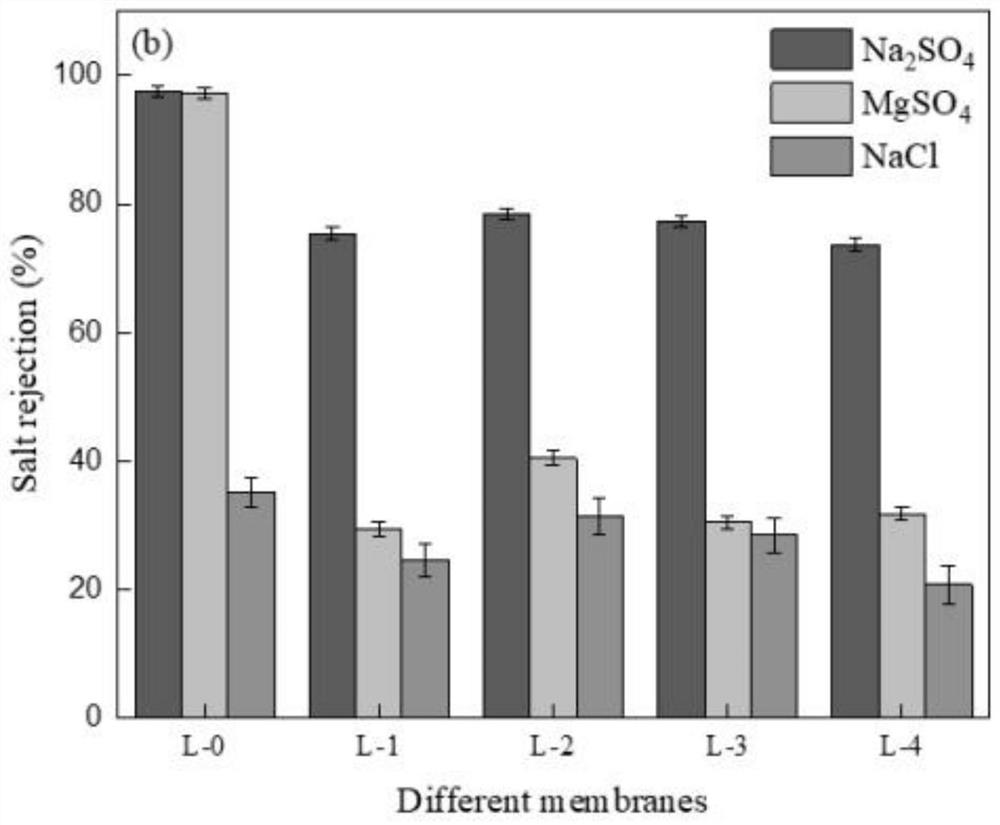

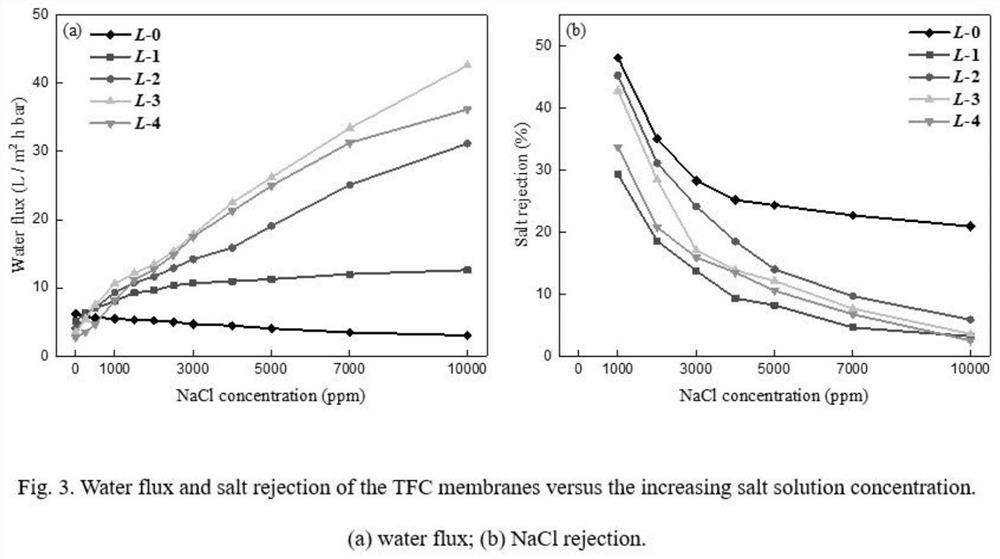

[0032] Wherein, the aqueous phase monomer solution may be an aqueous solution of L-lysine; the oil phase monomer solution may be an n-hexane solution (0.1 wt%) of trimesoyl chloride. All samples are represented by L-x in this example, whe...

Embodiment 2

[0037] Composite polyamide membranes were prepared as follows:

[0038] 1. Fix the asymmetric polysulfone ultrafiltration membrane (used as a support layer) on a glass plate and a Teflon frame, then pour the aqueous phase monomer solution into the Teflon frame, and soak the support layer for 1-10 minutes;

[0039] 2. Pour off the aqueous monomer solution, and use high-pressure gas to dry the surface moisture of the support layer (or use a rubber roller to remove moisture). Then pour the oil phase monomer solution into the surface of the support layer, and the interfacial polymerization reaction takes 30-600s;

[0040] 3. Pour off the oil phase monomer solution, rinse the surface with n-hexane and dry it, then immediately add the surface grafting aqueous solution to react for 1-10min. The prepared composite polyamide membrane was stored in distilled water at 4°C.

[0041] Wherein, the water phase monomer solution can be the aqueous solution (2wt%) of MPD or PIP; The oil phase m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com