Plug-in self-tapping threaded connecting device special for skirting type radiator field

A technology of self-tapping thread and connecting device, which is applied in the field of baseboard ring heating, can solve the problems of affecting market competitiveness, increasing installation costs, and difficult to control precision, and achieves the problems of difficult control of precision, saving processing costs, and avoiding corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

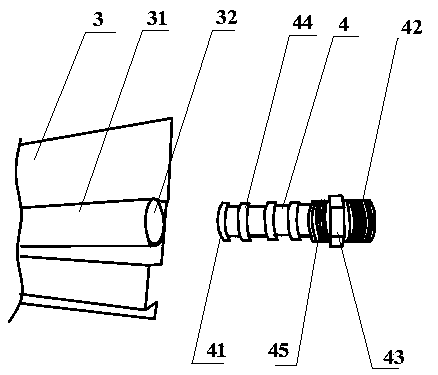

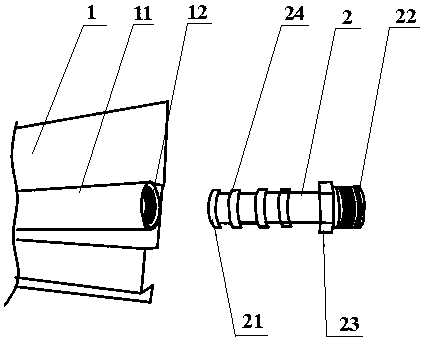

[0016] Such as figure 1 As shown, a special plug-in self-tapping thread connection device in the field of baseboard radiators includes a self-tapping thread joint 4, and the self-tapping thread joint 4 is composed of a plug-in joint 41, a threaded joint 42, a tight fixed point 43 and self-tapping thread 45, the self-tapping thread 45 is set on the side of the fastening point 43 close to the plug-in joint 41, the self-tapping thread joint 4 is rotated by rotating the self-tapping thread 45 during installation The pipes 31 fixed on the heat dissipation panel 3 are connected, and the outer wall of the self-tapping thread joint 4 is provided with a plurality of sealing grooves, and the sealing ring 44 is wrapped in the sealing grooves. The outer diameter of the above-mentioned self-tapping thread 45 is larger than the outer diameter of the joint 4 body, and larger than the inner diameter of the pipe 31 installed on the heat dissipation panel 3 .

[0017] The pipeline connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com