A mounting structure for gas film and a fermentation tank and a mounting method thereof

A technology for installation structures and fermentation tanks, applied in biochemical equipment and methods, gas production bioreactors, biochemical instruments, etc., can solve the problems of easily damaged airbags and occupying the internal space of fermentation tanks, so as to reduce the possibility and increase the installation Stability, the effect of reducing the possibility of gas film damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

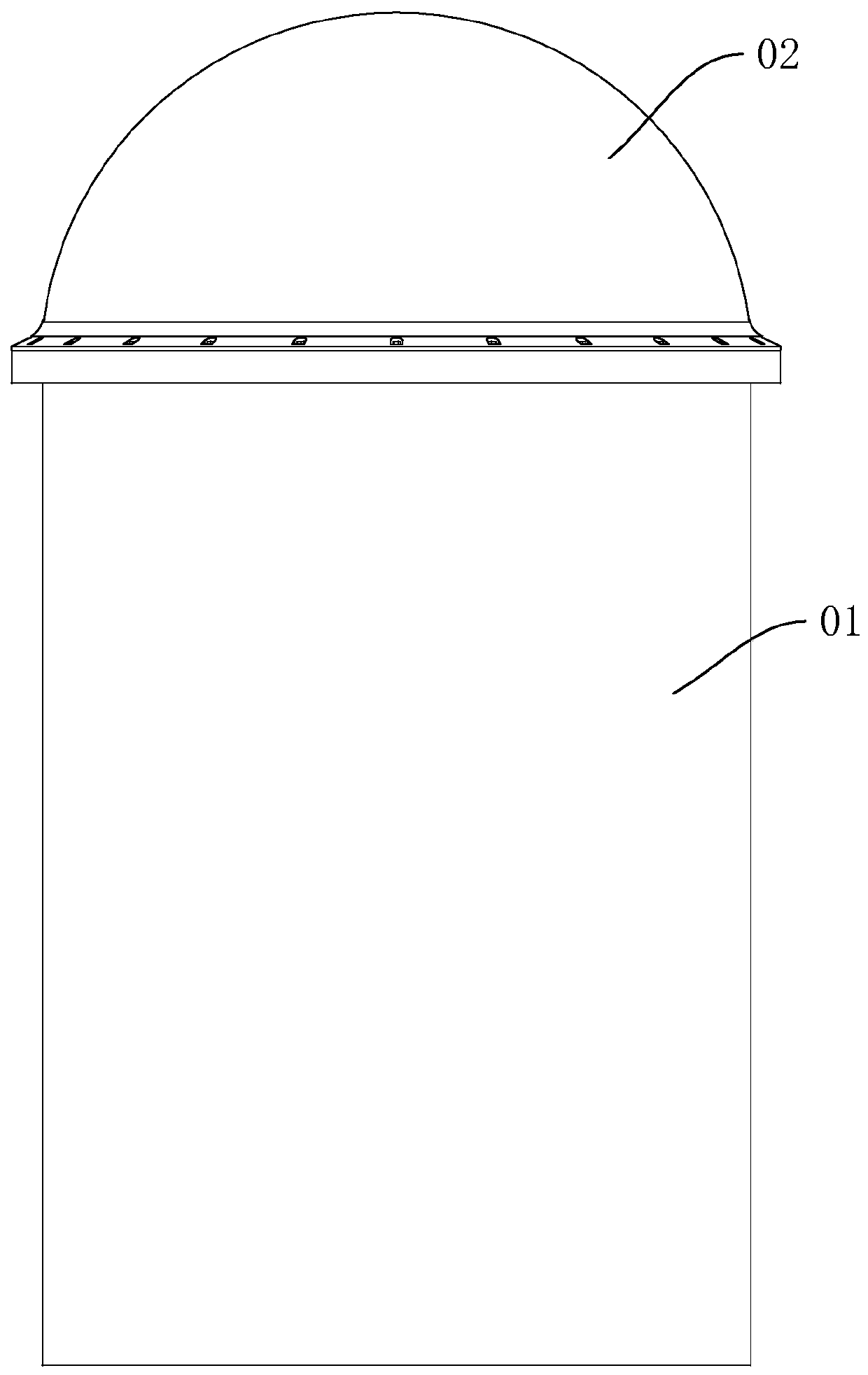

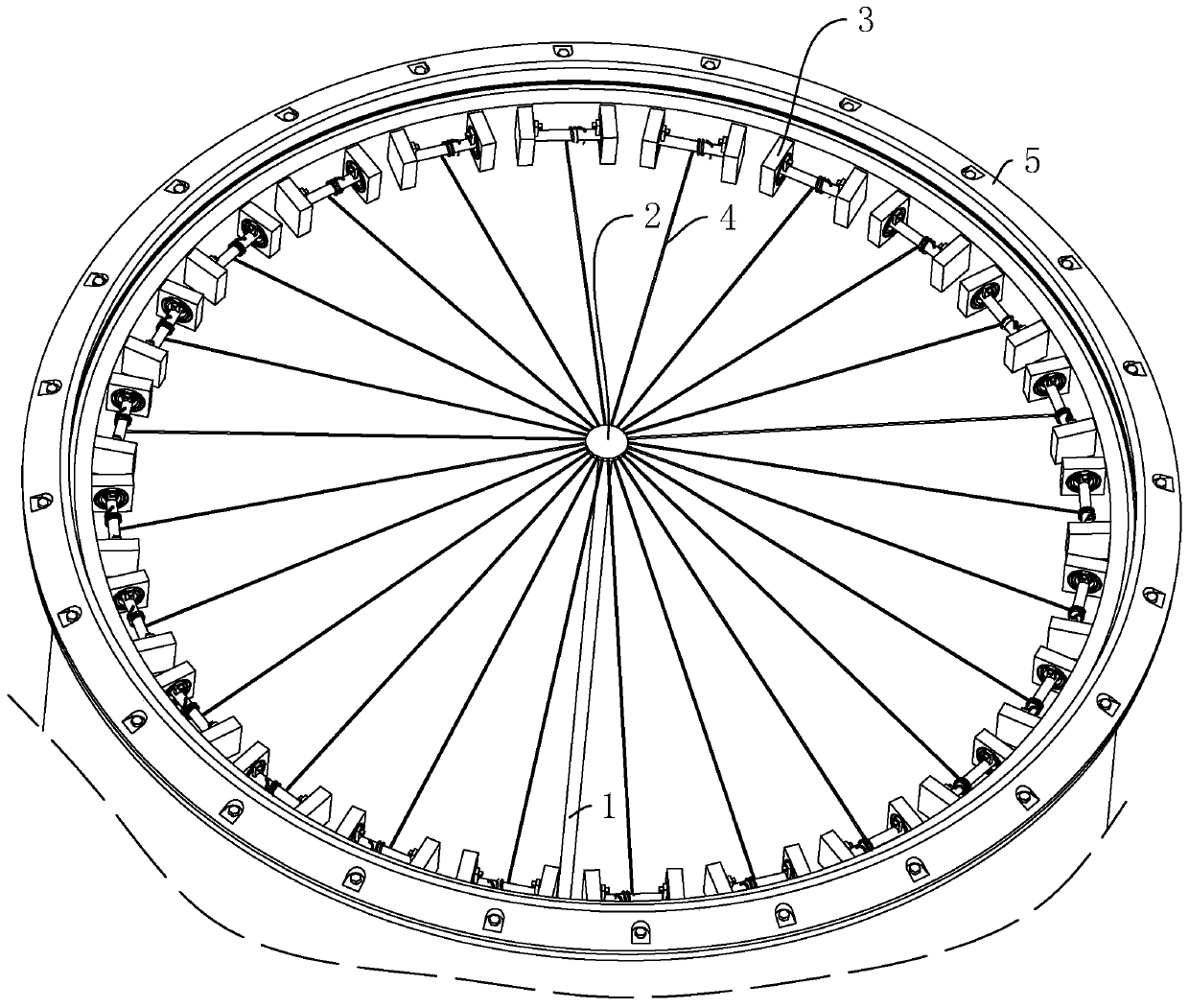

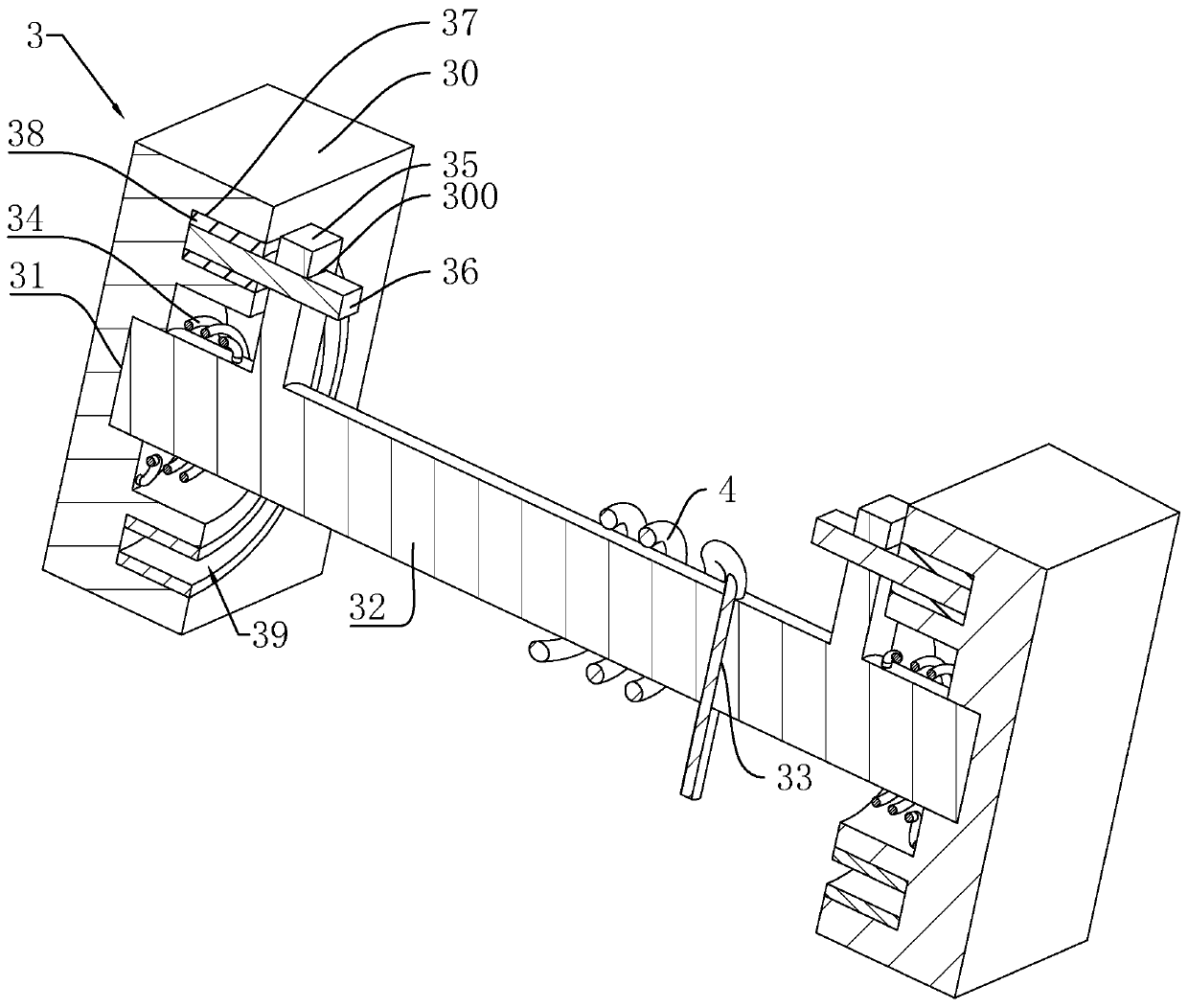

[0039] refer to figure 1 and figure 2, an installation structure of an air film and a fermenter, which includes a vertical bar 1 arranged on the inner bottom wall of the fermenter 01, a ring frame 2 arranged on the top wall of the vertical bar 1, arranged on the inner wall of the fermenter 01, and Several connecting frames 3 evenly distributed along the circumference of the fermenter 01, preferably twenty-four connecting frames 3, the connecting frames 3 are located on the top of the fermenting tank 01, and a rope 4 is connected between the ring frame 2 and the connecting frame 3, preferably cotton rope , the outer wall of the fermenter 01 is provided with a ring frame 5 for fixing the air film 02, and the air film 02 adopts a double-layer film; when the air film 02 is installed, the vertical rod 1 is installed on the bottom wall of the fermenter 01, and the ring The frame 2 is installed on the top wall of the vertical bar 1, the connecting frame 3 is installed on the inner ...

Embodiment 2

[0049] A method for installing an air film and a fermenter, the specific method is as follows:

[0050] (1) Weld the vertical bar on the bottom wall of the fermenter, then weld the ring frame on the top wall of the vertical bar, weld the support plate on the inner side wall of the fermenter, install the support bar in the positioning hole, and place the twist One end of the spring is installed on the support rod, and the other end is installed on the support plate;

[0051] (2) Expand the torsion spring to store force, fasten one end of the rope to the ring frame, pass the other end through the through hole and then fasten it to the support rod. After loosening the rope, the rope can be tightened to increase the rope support air Membrane stability, reducing the possibility of air film drooping into the fermenter and affecting the feeding of the fermenter;

[0052] (3) Weld the positioning ring plate on the outer wall of the fermentation tank, hoist the air film above the ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com