A light-curing environment-friendly flexible PVC stain-resistant matte finish and preparation method thereof

A stain-resistant matte finish paint, an environmentally friendly technology, applied in the field of coatings, can solve the problems that the toughness cannot meet the requirements of soft PVC, the matte paint cannot meet the stain resistance and easy to clean, and the physical and chemical properties of the paint film are poor. Achieve long-lasting stain resistance, good stain resistance, and improved matting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A preparation method for light-curing environment-friendly flexible PVC stain-resistant matte finish, comprising the following steps:

[0047] (1) Weigh each component by weight, add silicone modified resin, urethane acrylate and acrylate monomer into the dispersion tank, first stir evenly at 400-600r / min, then stir at 1200-1500r / min Disperse for 10-15 minutes;

[0048] (2) Add photoinitiator and dispersant, and disperse at 800-1000r / min for 10-15min;

[0049] (3) Add matting agent under stirring, stir evenly, and disperse at 1200-1500r / min for 10-15min;

[0050] (4) Add anti-settling agent, leveling agent and defoamer, stir evenly, and disperse at 1200-1500r / min for 10-15min;

[0051] (5) Filter through a 300-mesh filter cloth and pack.

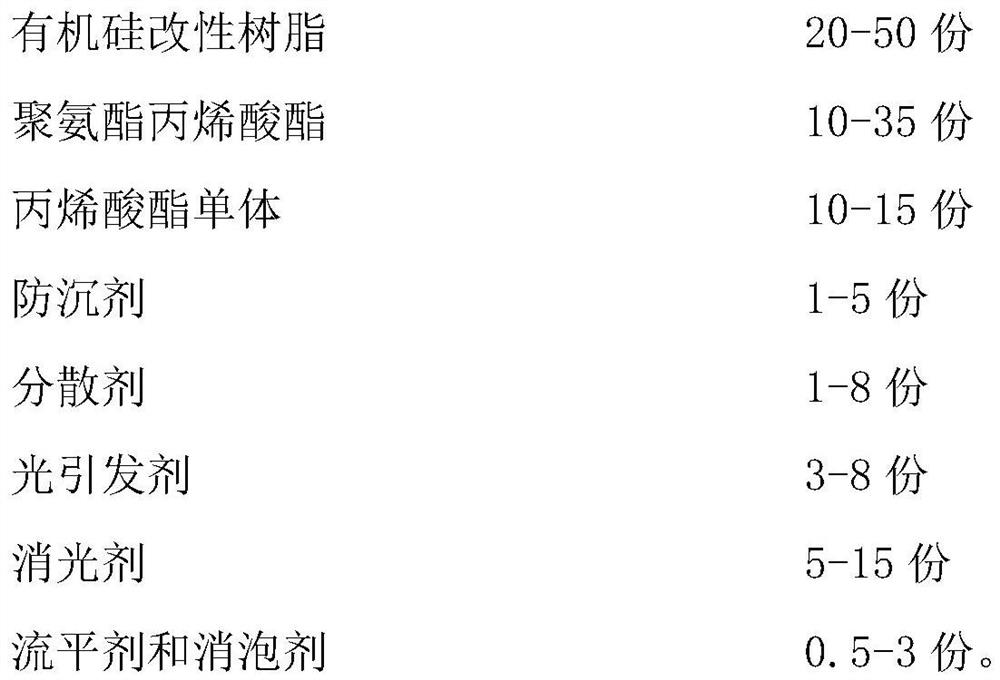

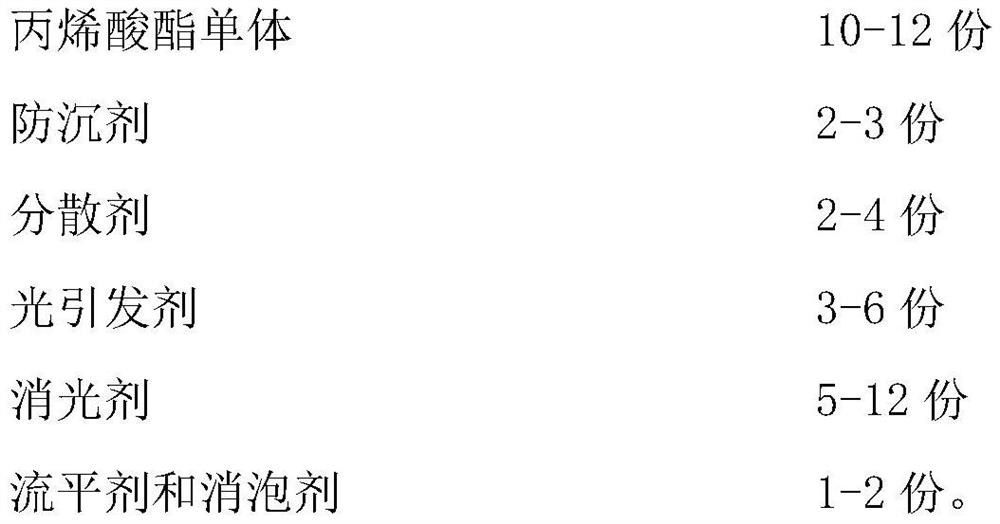

[0052] See Table 1 for details of the components and their weight percentages in Examples 1-4 and Comparative Examples 1-5.

[0053] Table 1

[0054]

[0055]

[0056] The preparation method of the unmodified polyurethane res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com