Truck loading pose adjusting device and adjusting method thereof

A technology for adjusting the position and posture of a truck, which is applied to a truck loading posture adjustment device and its adjustment field, can solve the problems of difficulty in accurately parking the truck on the loading space, and saves labor costs, improves loading efficiency and maintenance costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

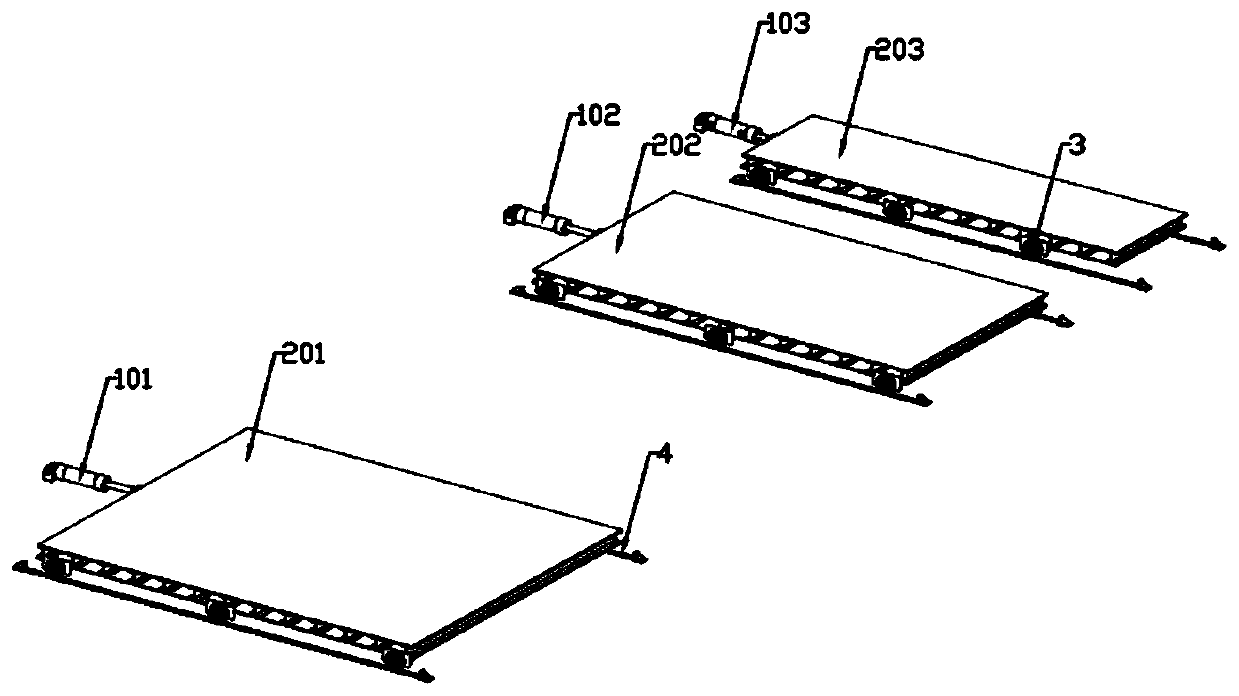

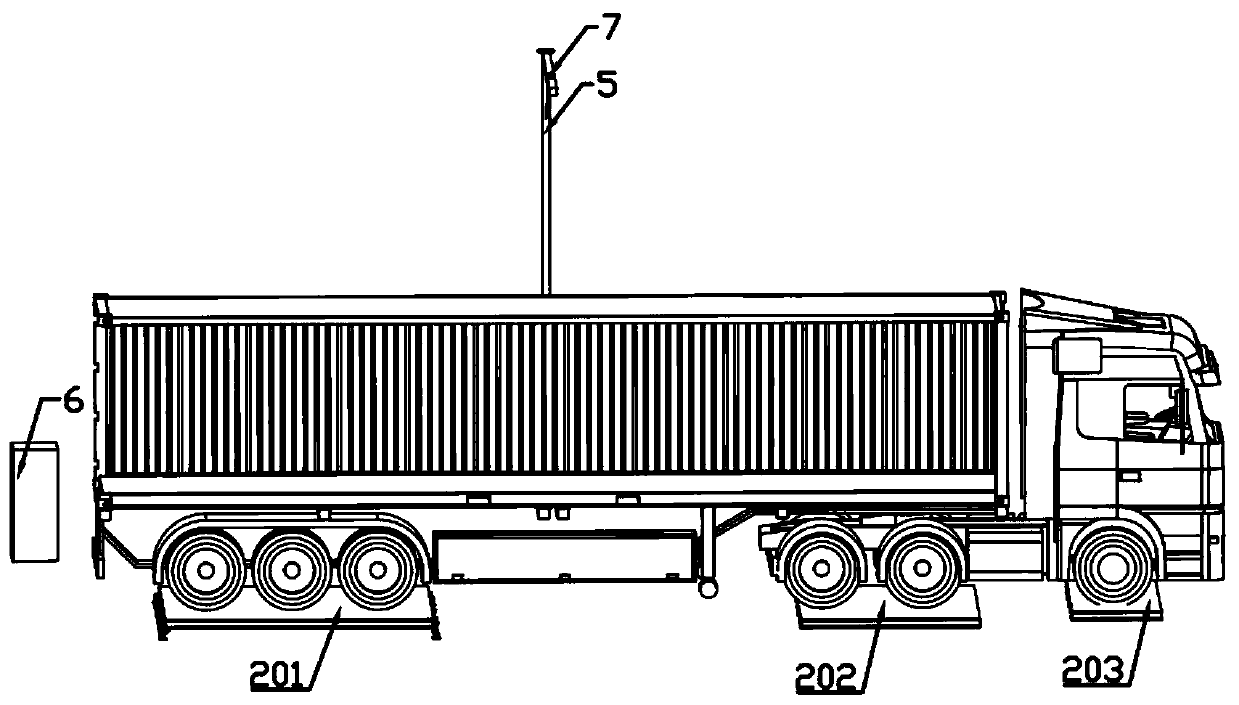

[0040] A truck loading posture adjustment device, such as Figure 1~3 As shown, it includes mobile platforms 201, 202 and 203, steel wheels 3 located under both sides of the mobile platform and hydraulic cylinders 101, 102 and 103 for driving the mobile platforms 201, 202 and 203 respectively;

[0041] There are three sets of mobile platforms, which are respectively located in three pits on the ground, and the distances between the three sets of mobile platforms correspond to the intervals between the three sets of wheels of the truck. Guide rails 4 are arranged under the steel wheels 3 in the pits, and the guide rails 4 is arranged along the width direction of the standard truck, the length of the guide rail is greater than the width of the truck, and the steel wheel 3 slides along the guide rail 4 to realize the movement of the mobile platform along the width direction. The guide rail 4 is a straight guide rail, which is laid on the corresponding position of the pit on the g...

Embodiment 2

[0043] A truck loading posture adjustment device, the structure is as shown in Embodiment 1, the difference is that three pits are provided on the ground, and the mobile platforms 201, 202, and 203 are respectively located in the three pits, and the upper part of the mobile platform is The height of the surface is consistent with the ground, and the truck can be parked directly by the driver to prevent bumps and facilitate the transportation of fragile goods.

Embodiment 3

[0045] A truck loading posture adjustment device, the structure is as shown in Embodiment 1, the difference is that the number of hydraulic cylinders is three groups, and the three groups of hydraulic cylinders are located on the same side of the mobile platform, and are used to drive the three groups of mobile platforms respectively exercise. When adjusting the posture, the hydraulic cylinder will drive the mobile platform to move along the guide rail, so as to adjust the relative position and angle of the truck relative to the loading equipment through the movement of the mobile platform, quickly adjust the posture of the truck, save the time of manual adjustment, and Realize high-efficiency automated loading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com