A kind of solid tire and its production method

A technology of solid tires and water tanks, applied in tire measurement, tire parts, tires, etc., can solve the problems of not being able to adjust the temperature of tires and road surface in time, large tire wear, and reduced heat dissipation effect, so as to avoid temperature rise and wear and increase flow properties, water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

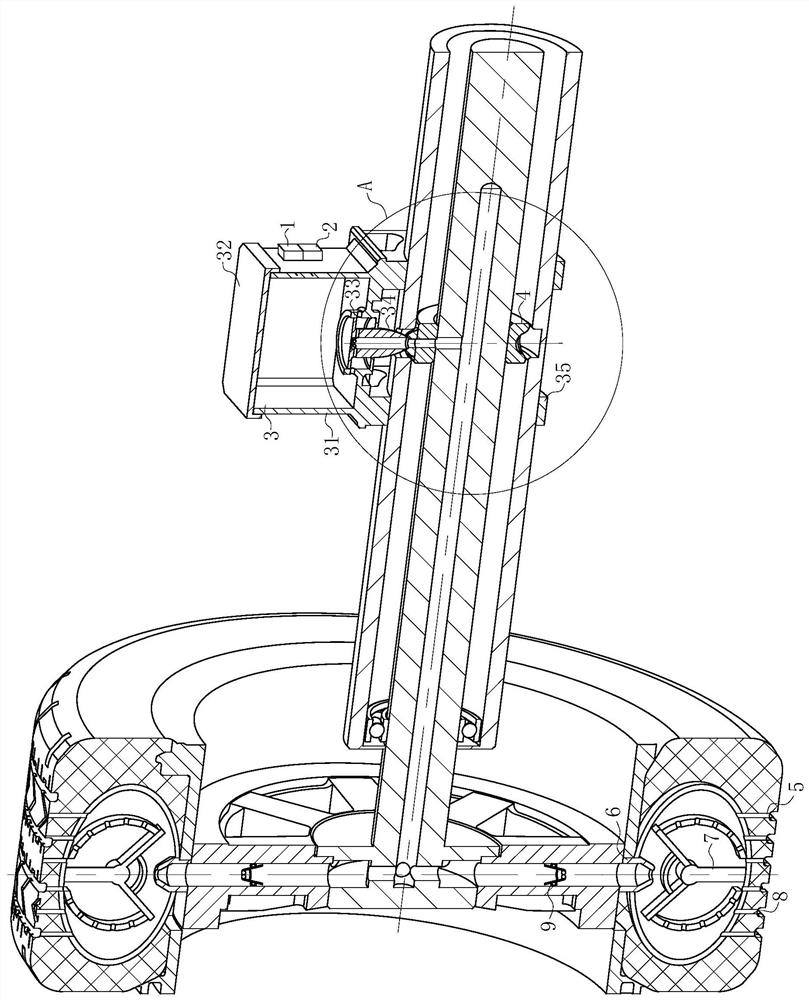

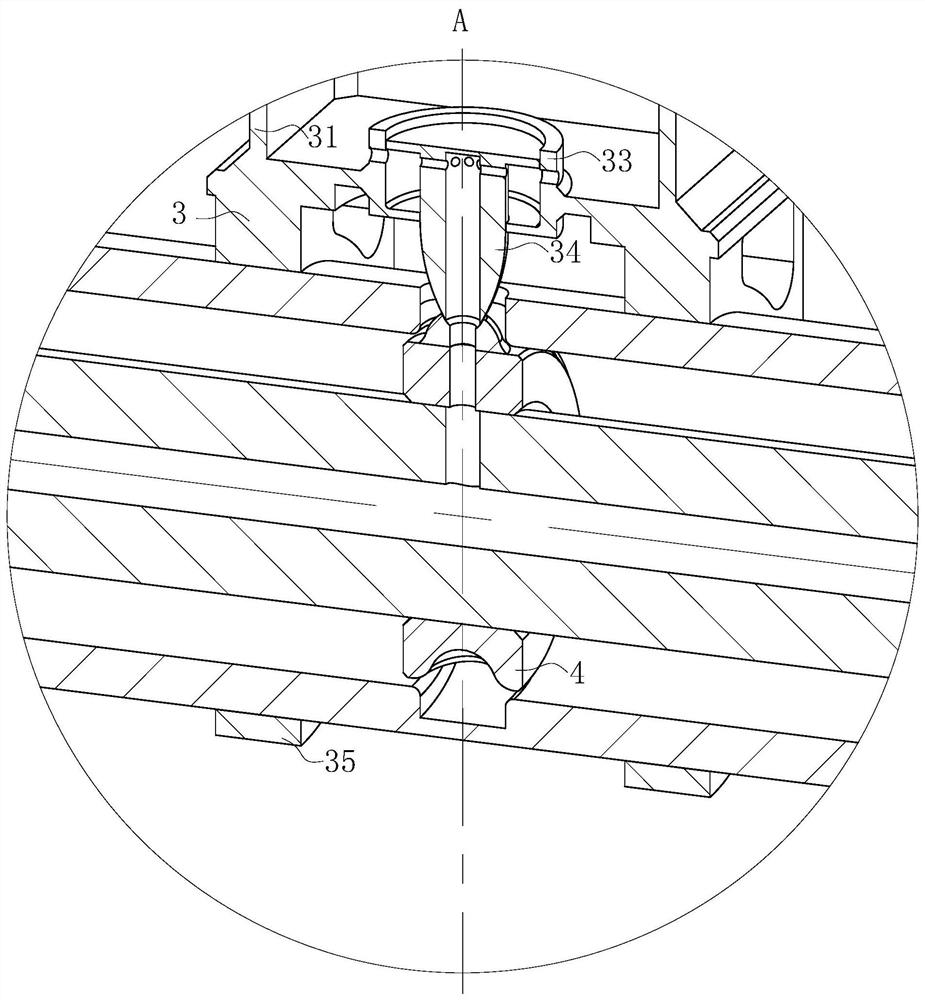

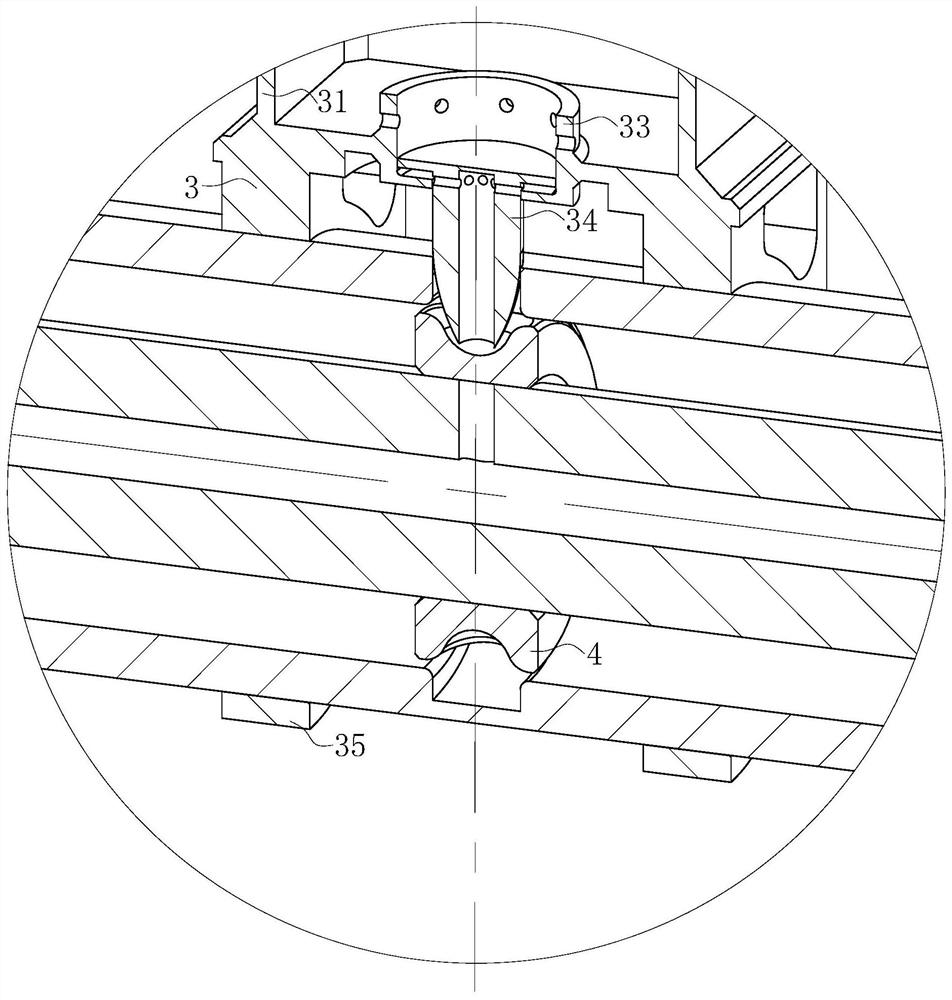

[0031] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with the specific embodiments. figure 1 as the benchmark.

[0032] like Figure 1 to Figure 8 As shown, a solid tire according to the present invention includes a controller 1, a temperature control switch 2, a water tank 3, a collar 4, a water outlet 5, a conical port 6, a cooling unit 7, a spring sheet 8, a one-way inlet The water unit 9, the controller 1 is used to control the operation of the temperature control switch 2; the water tank 3 is fixedly connected to the rear axle of the automobile; the collar 4 is fixed on the drive shaft inside the rear axle of the automobile, the collar 4 Located below the water tank 3; one end of the water outlet hole 5 is located in the pattern groove of the solid tire, and the other end of the water outlet hole 5 is located in the ellip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com