Production method of new energy automobile motor aluminum shell

A new energy vehicle and production method technology, which is applied to the new energy vehicle motor housing manufacturing production method or production field, can solve problems such as energy consumption reduction, and achieve the effects of low production efficiency, significant energy saving effect, and no heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

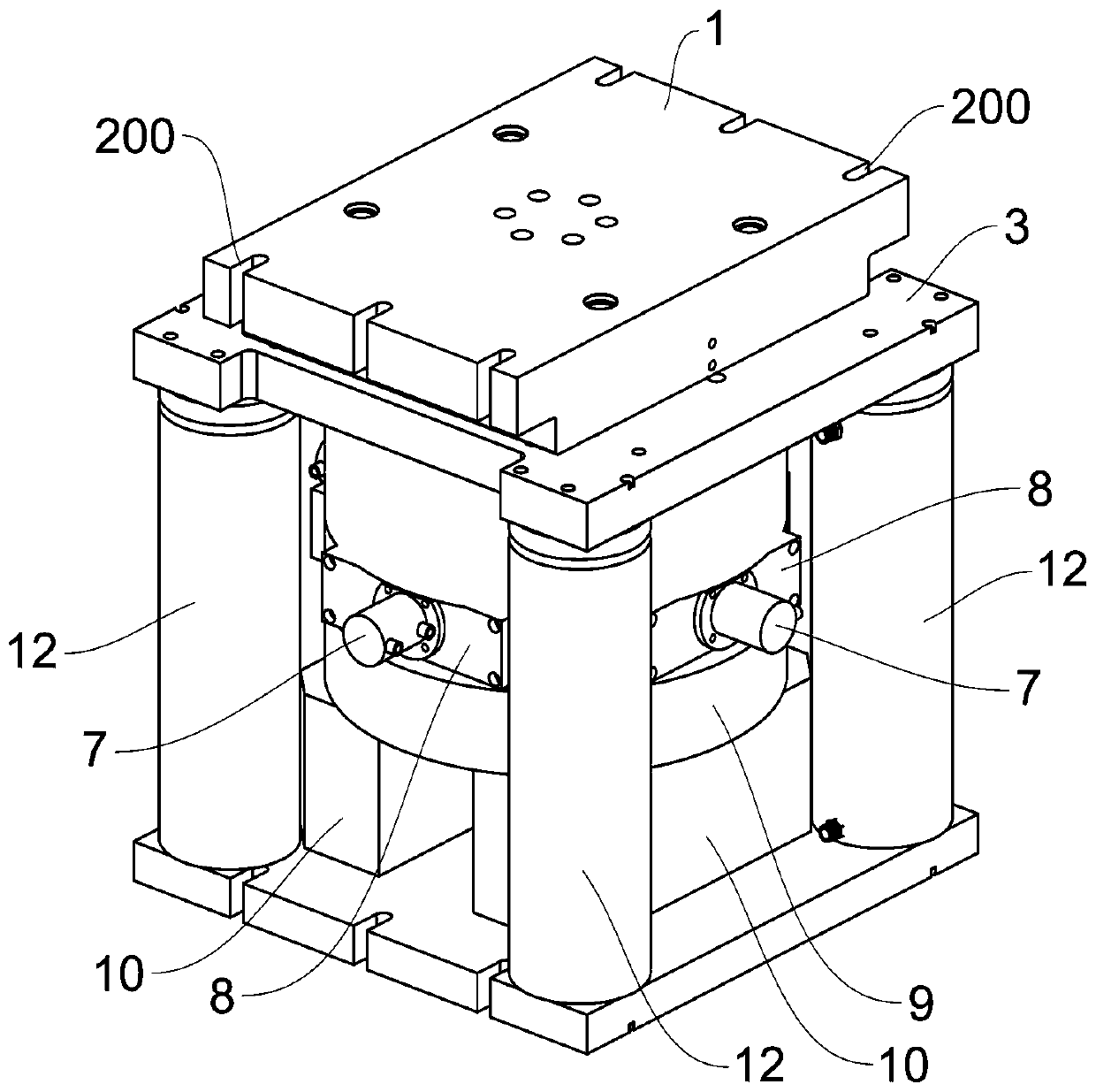

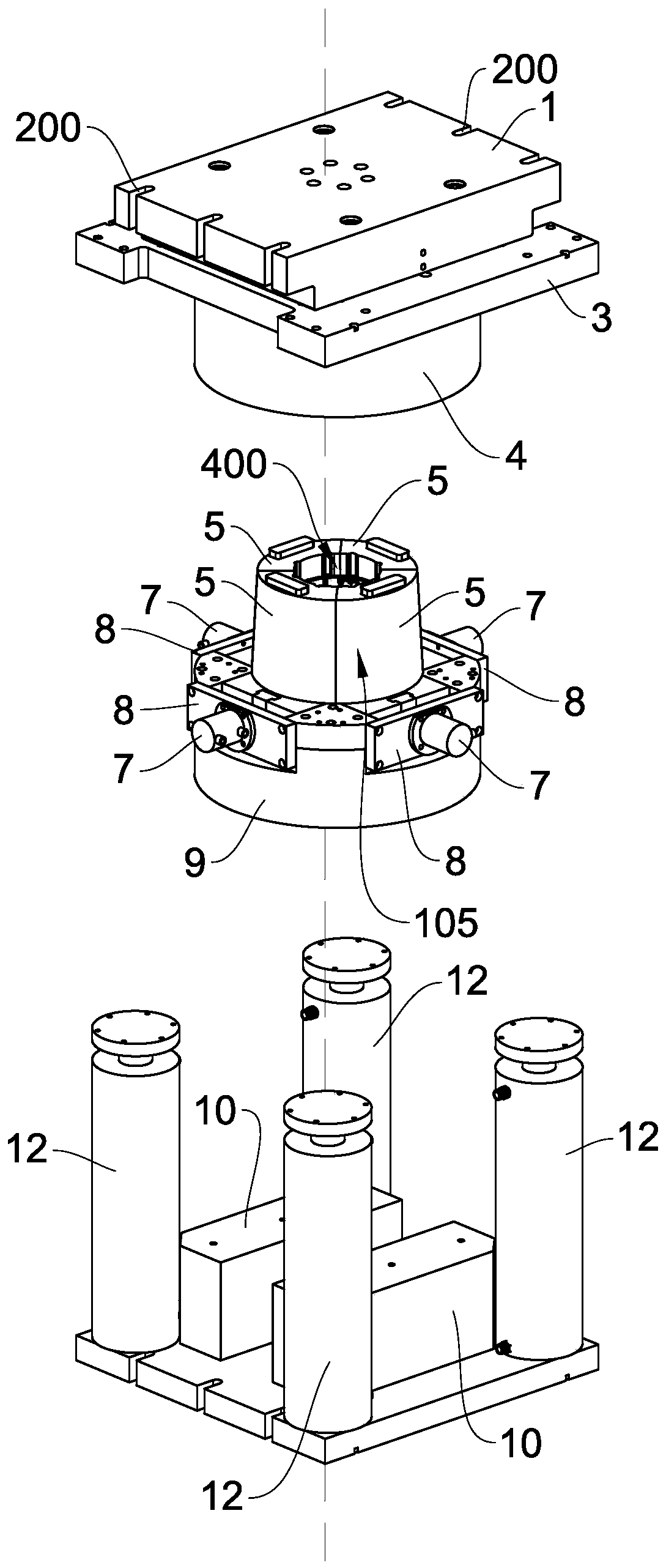

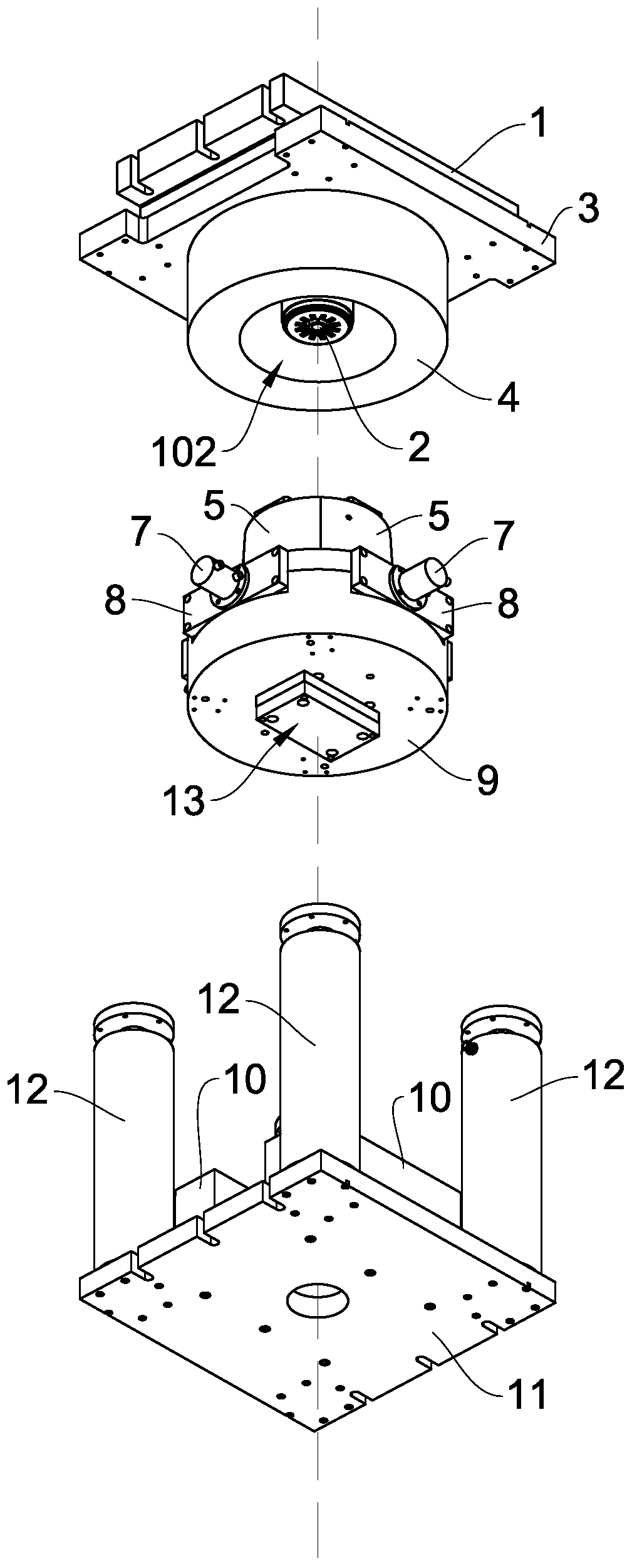

[0027] Such as Figure 1 to Figure 13 As shown, the production method of a new energy automobile motor aluminum housing described in the present invention uses the following hardware devices to implement the production method: an outer shell mold device, an inner shell mold device, and an end cover mold device.

[0028] Such as Figure 1 to Figure 6 As shown, the outer shell mold device and the inner shell mold device respectively include a punch fixing plate 1, a punch 2, an upper template 3, a locking block 4, a slider 5, a mold core 6, a core pulling cylinder 7, and a mold base 9 , Die foot 10, lower template 11, column oil cylinder 12, etc.

[0029] Such as Figure 1 to Figure 3 As shown, the punch fixing plate 1 is also provided with a U-shaped groove 200 to realize the installation of the mold on the upper machine table of the die-casting machine. The punch fixing plate 1 and the punch 2 are fixed together. Specifically, as Figure 4 As shown, the bottom surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com