Gold mold casting mold of runner/riser cutting mechanism

A technology of cutting mechanism and casting mold, applied in casting molding equipment, casting mold, core and other directions, can solve problems such as increasing production cost and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

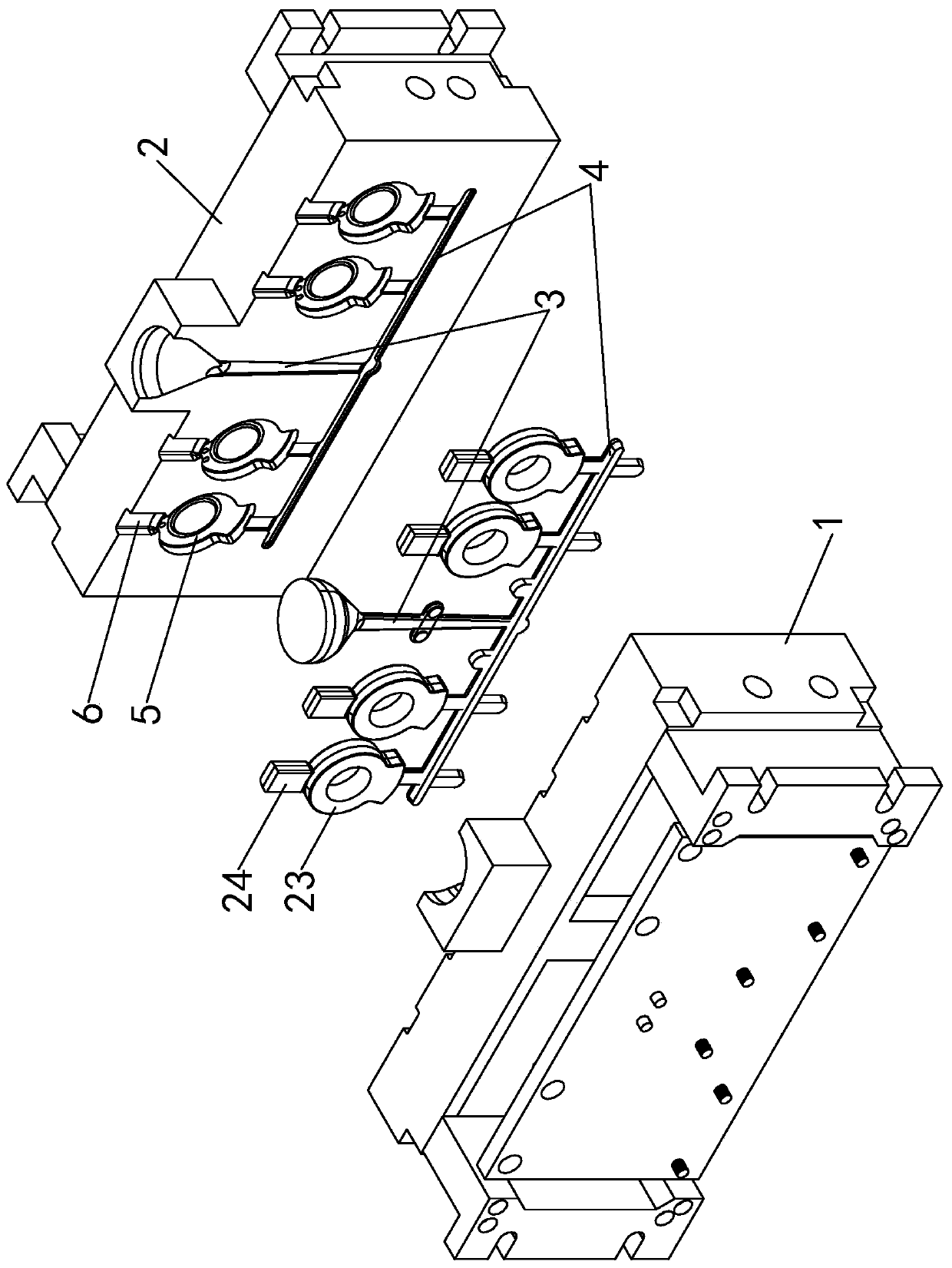

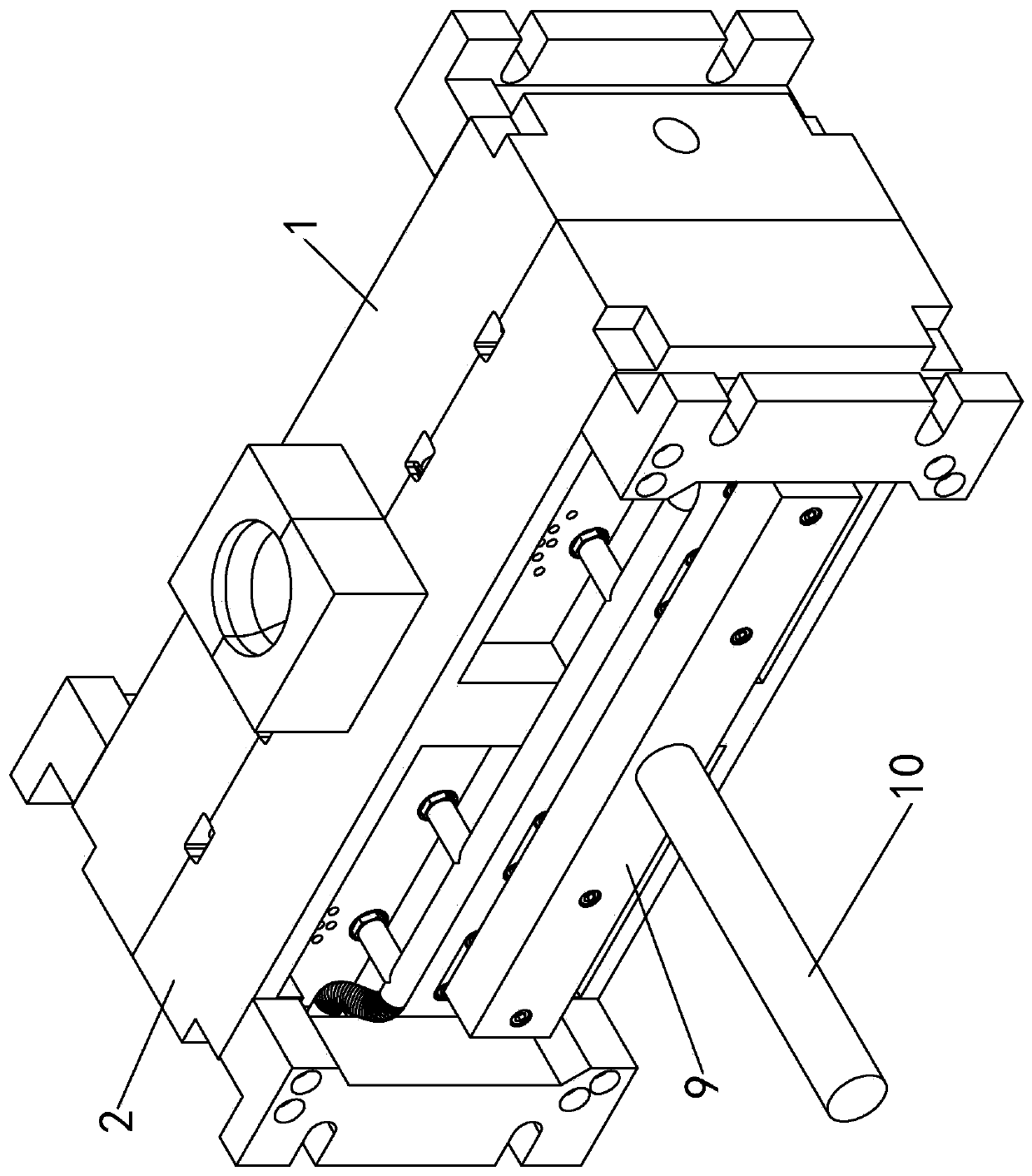

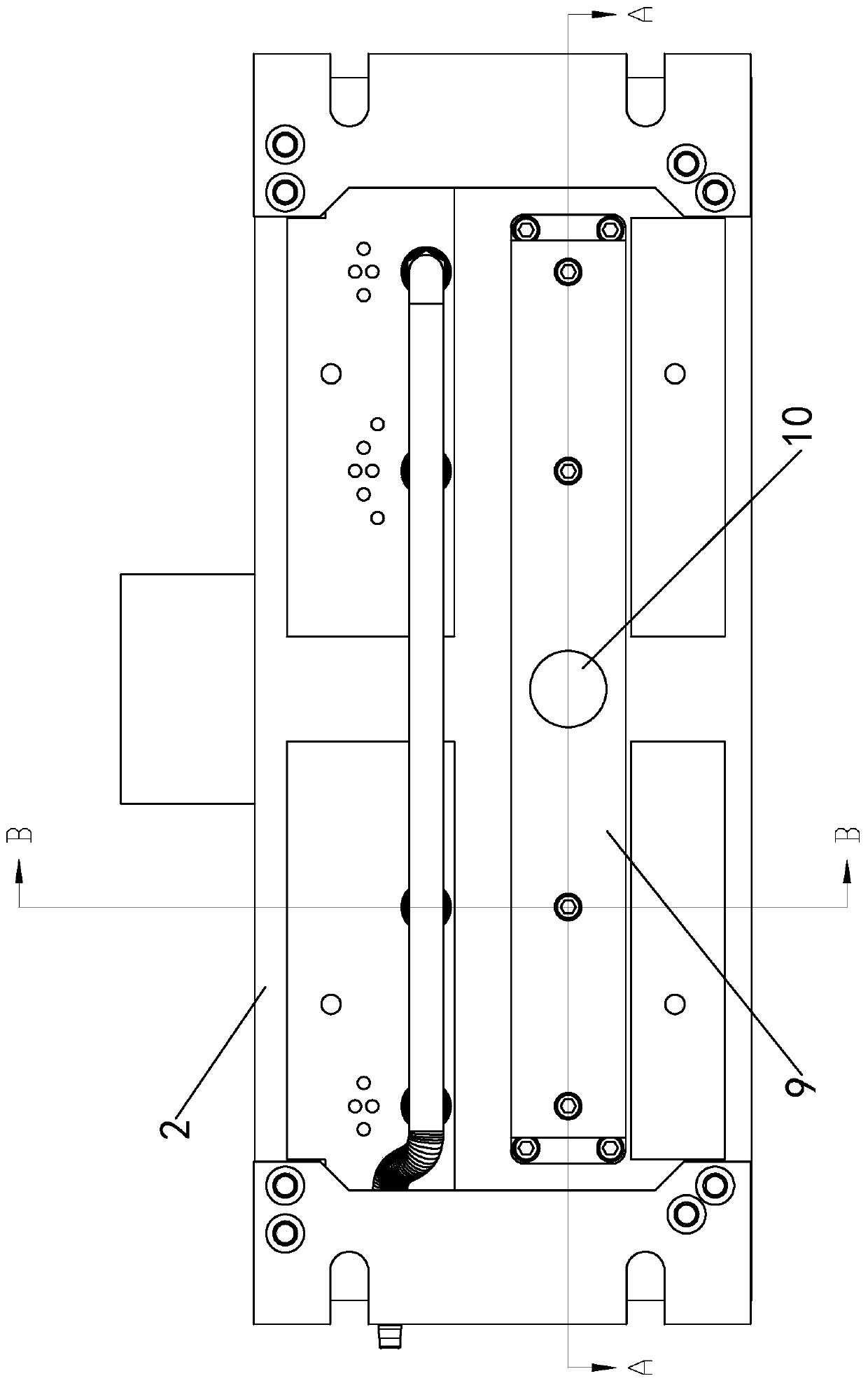

[0024] refer to Figure 2 to Figure 5 , the present invention is a gold casting mold with a runner / riser cutting mechanism, including a movable mold 1 and a fixed mold 2 arranged oppositely, and a vertical runner 3, a horizontal pouring channel 3 is formed between the movable mold 1 and the fixed mold 2 Channel 4 and several product cavities 5 and riser cavities 6, the upper end of each product cavity 5 is communicated with the corresponding riser cavities 6, the lower ends are respectively communicated with the runner 4, and the upper end of the vertical runner 3 is communicated with The sprue cup is connected with the runner 4 at the lower end. The sprue cup is formed by the sprue block arranged on the top of the movable mold 1 and the top of the fixed mold 2. There is a breakable between the product cavity 5 and the riser cavity 6. In the groove forming part 7, there is a breakable gate 8 between the product cavity 5 and the runner 4, and two cutting mechanisms are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com