A quick-detachable self-sealing jumper hose connection device for offshore floating devices

A floating device and hose connection technology, which is applied in the direction of hose connection devices, connections with fluid cut-off devices, pipes/pipe joints/pipe fittings, etc., and can solve the problem of inability to connect multiple jumper hoses 1 and two Solve problems such as body separation, save manpower, avoid liquid corrosion, and prolong the life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

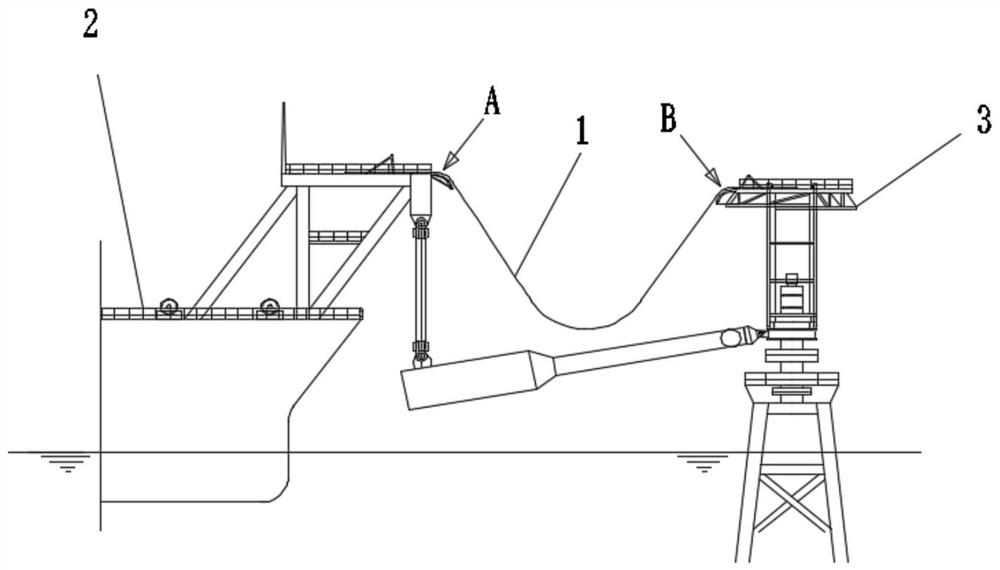

[0029] like Figure 1 to Figure 6 As shown, the present invention is a quick-separating and self-sealing offshore floating device bridging hose connection device, comprising a first separation body and a second separation body;

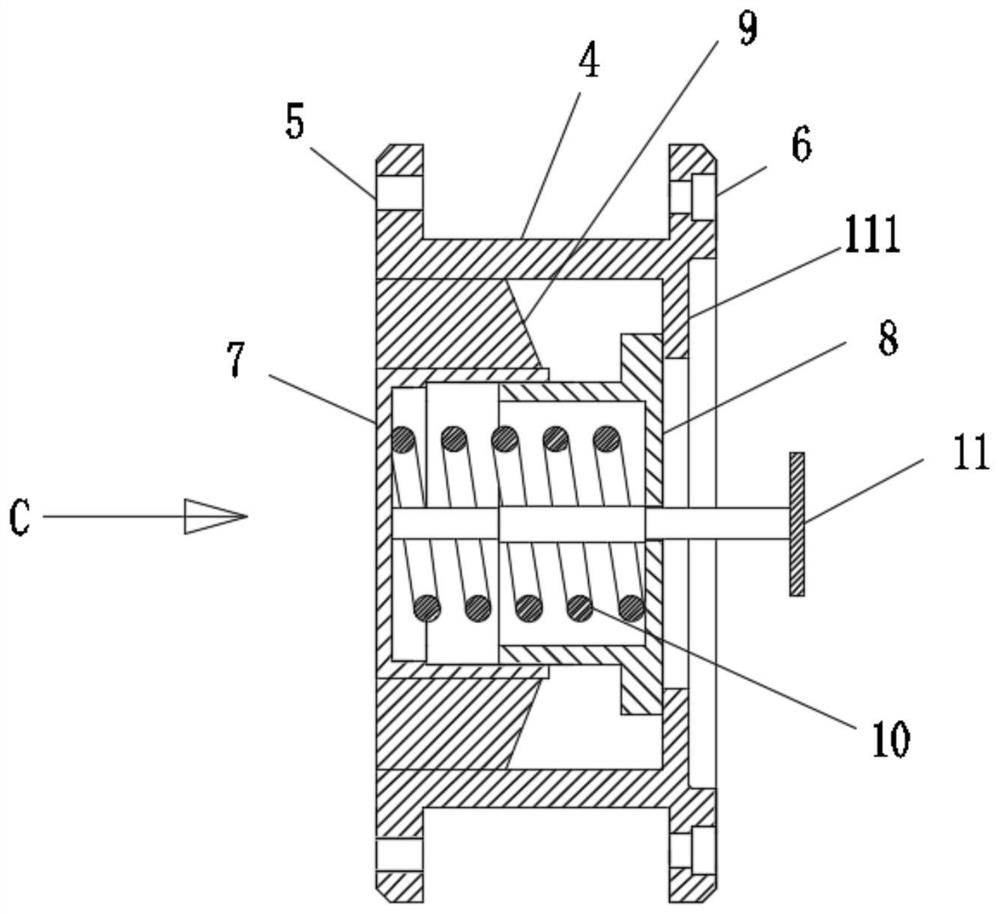

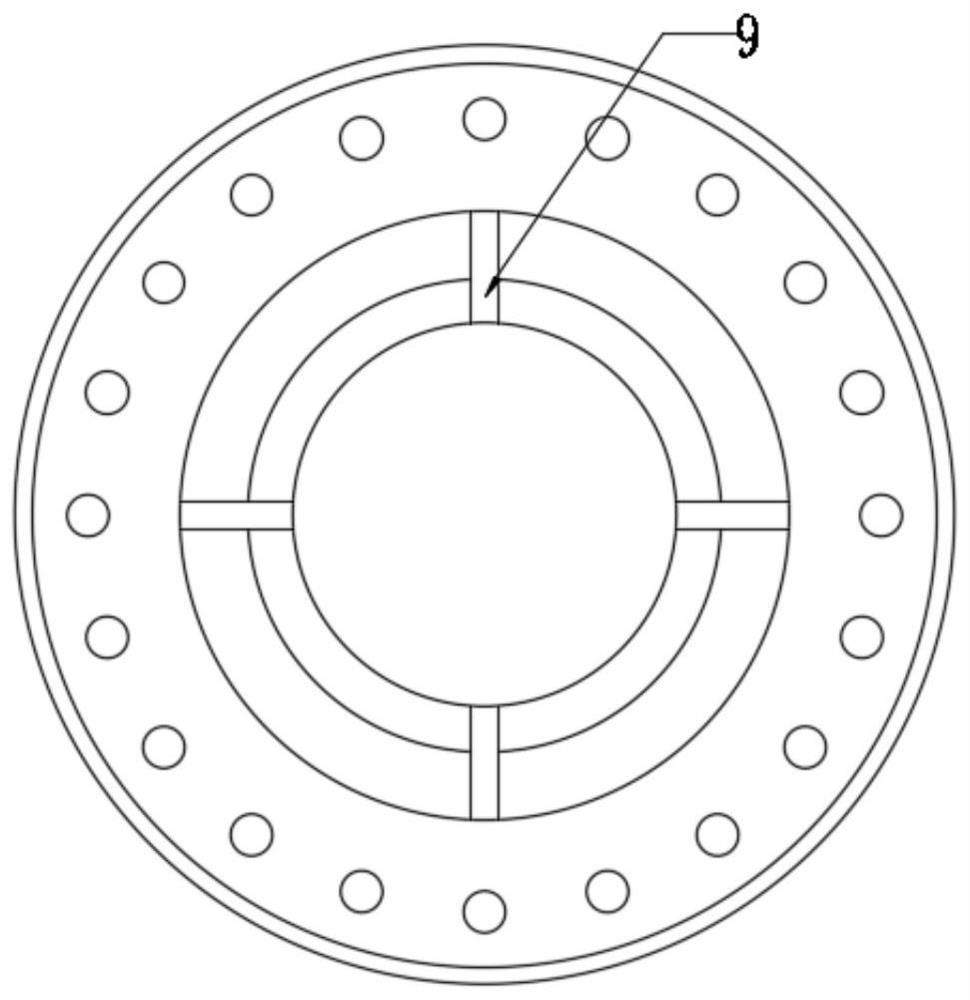

[0030] The first separation body includes a first pipeline 4 with a first flange bolt opening 5 at one end and a first explosion bolt opening 6 at the other end. The first pipeline 4 is perpendicular to one end of the first flange bolt opening 5 . A first rib 9 is connected inside, and the first rib 9 is connected to a first sleeve base 7 arranged in the first pipeline 4;

[0031] A first blocking plate 111 is vertically connected inward at one end of the first explosion bolt port 6 of the first pipeline 4; a first sleeve 8 is arranged between the first sleeve base 7 and the first blocking plate 111; The sleeve 8 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com