Anesthesia waste gas extraction and purification equipment for anesthesia room

A technology for purification equipment and anesthesia room, which is applied in the field of anesthesia waste gas extraction and purification equipment for anesthesia room, can solve problems such as inability to achieve effect, ozone depletion, bacterial pollution and the like, and achieve the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following text, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments, however, it will be apparent to those skilled in the art that the described embodiments can be used without these specific details. Some or all instances were practiced, and in other instances well-known process steps were not described in detail.

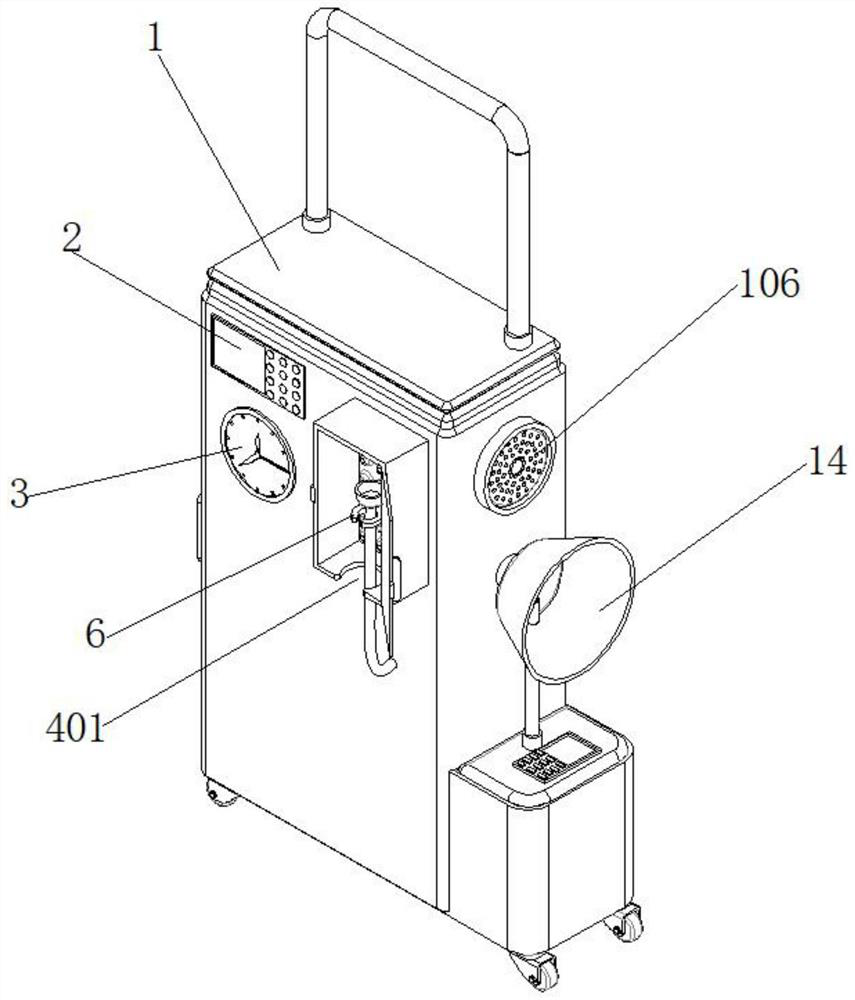

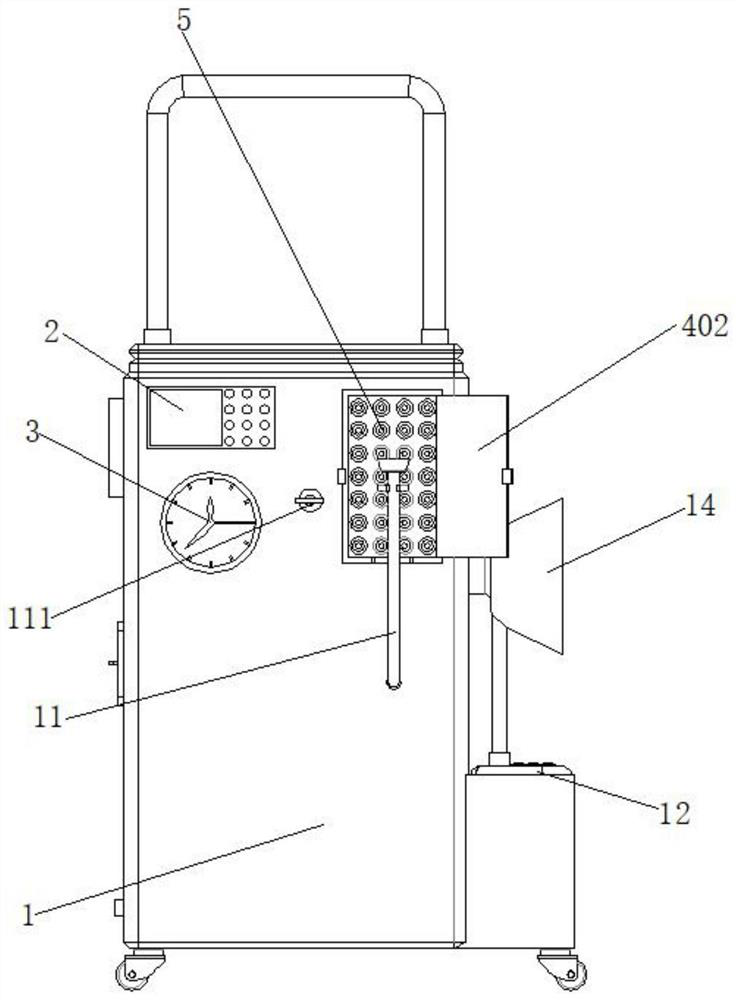

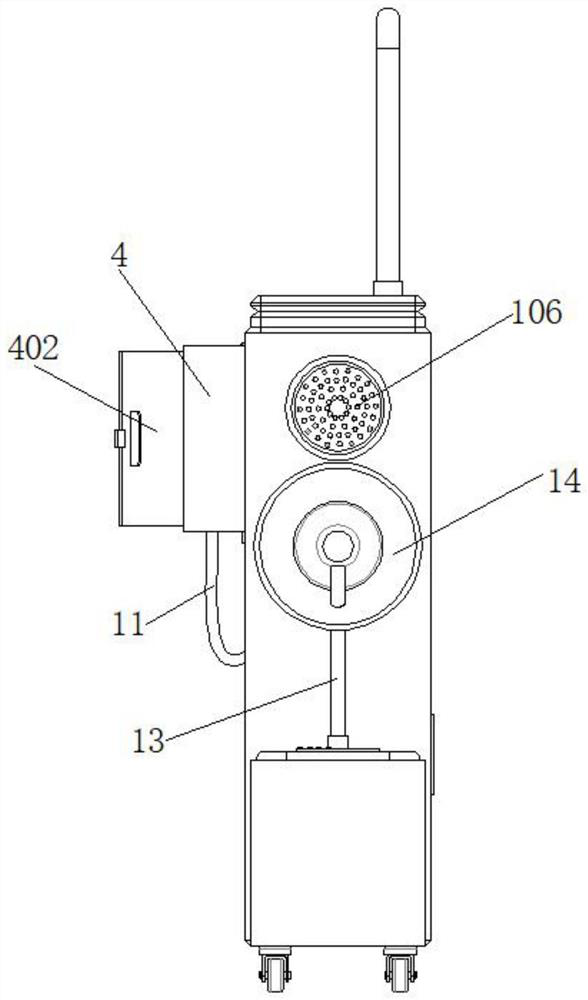

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, it includes housing 1, control panel 2, timer 3, protective cover 4, ultraviolet germicidal lamp 5, card holder 6, placement slot 7, I filter element 8, suction pump 9, branch pipe 10, telescopic bellows 11 , oxygen generator 12, exhaust pipe 13, shroud 14, drawer box 15, II filter element 16, the control panel 2 is fixed on the upper left side of the outer wall of the housing 1, the control panel 2 and the housing The body 1 is connected by bolts, the tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com