Method for producing dialkylaminosilane

A technology of alkylaminosilane and its manufacturing method, which is applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve problems such as volume efficiency reduction, and prevent runaway reactions and reduce halogen content Less, good yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

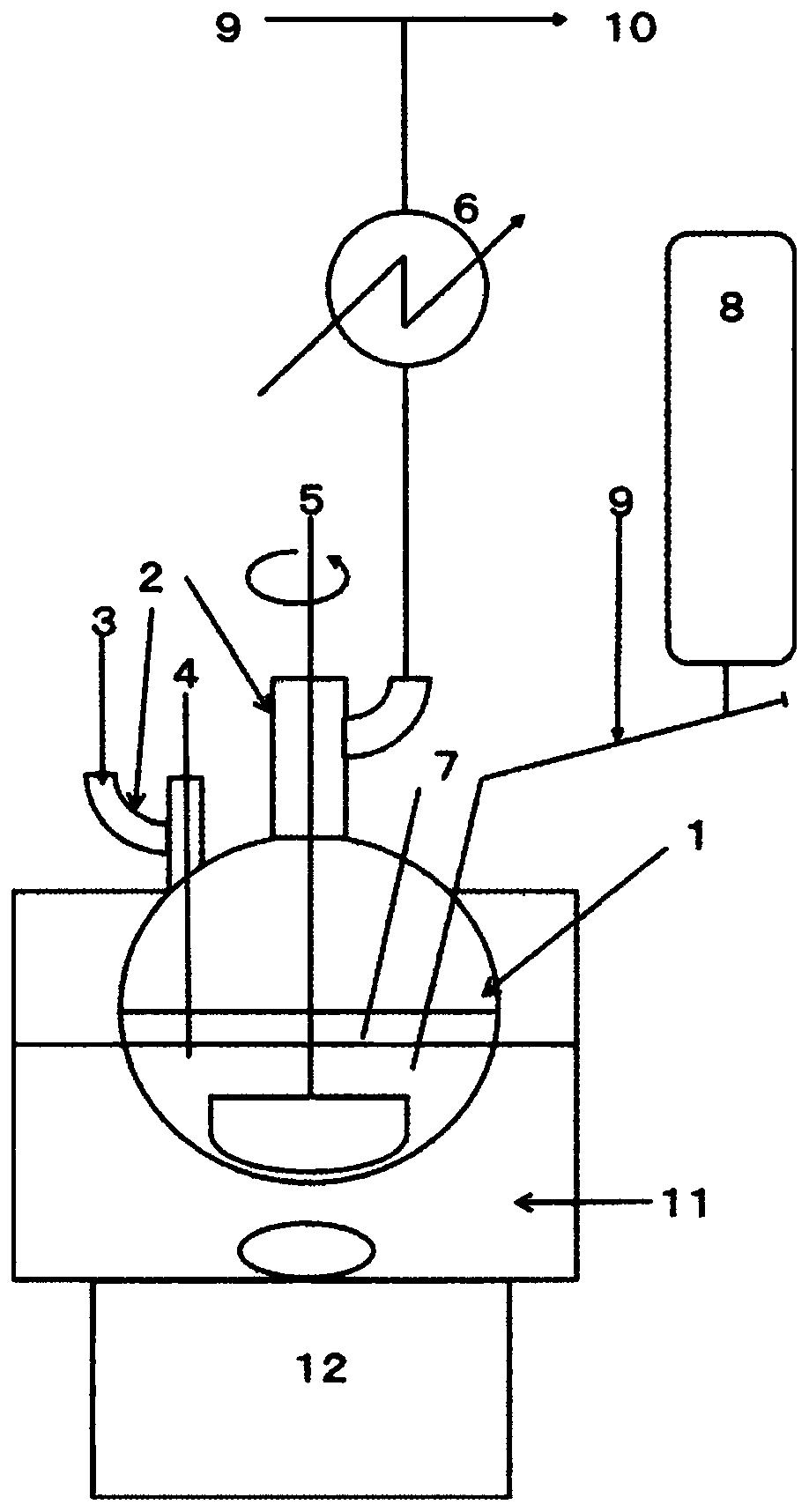

Image

Examples

Embodiment 1

[0068]

[0069]

[0070] 7.66 g (0.32 mol) of magnesium and 90 g of n-heptane were placed in a 300 mL four-necked flask. While stirring, the oil bath was heated to 115° C., kept in a reflux state for 1 hour, and the solvent and moisture in the apparatus were reacted with magnesium to perform dehydration. After that, the oil bath was left to cool with ice water. 40.8 g (30 mL, 0.30 mol) of trichlorosilane (TCS) was charged in a 50 mL supply tank, and when the internal temperature dropped to 5° C., 3 mL of TCS was charged into a 300 mL four-necked flask. Dimethylamine (DMA) was supplied from the gas phase portion of the flask at a rate of 16 mL per minute while maintaining 10° C. or lower for 1 hour.

[0071]

[0072] The cooling with ice water was stopped, and the 300 mL 4-necked flask was immersed in the oil bath again, the oil temperature was set to 90° C., and the temperature of the reaction solution was heated to 80° C. or higher. During the heating, the reaction be...

Embodiment 2

[0078]

[0079]

[0080] 7.64 g (0.31 mol) of magnesium, 60 g of n-heptane, and 30 g of 1,2-dimethoxyethane (DME) were placed in a 300 mL four-necked flask. While stirring, the oil bath was heated to 115° C. and kept under reflux for 1 hour to dehydrate the solvent and moisture in the apparatus by reacting with magnesium, and then cooled with ice water. 45.0 g (32 mL, 0.33 mol) of TCS was charged into a 50 mL supply tank, and when the internal temperature dropped to 5° C., 3 mL of TCS was charged into a 300 mL four-necked flask. DMA was supplied from the gas phase portion of the flask at a rate of 37 mL per minute while maintaining 10° C. or lower for 1 hour.

[0081]

[0082]The oil bath was set at 90°C, and the temperature of the reaction solution was heated to above 80°C. During the heating, the reaction between the hydrochloride salt of DMA and magnesium occurred, but a significant rapid rise in temperature was not observed. When the internal temperature exceeded ...

Embodiment 3

[0088]

[0089]

[0090] 5.10 g (0.21 mol) of magnesium, 60 g of n-heptane, and 15 g of THF were placed in a 300 mL four-necked flask. While stirring, the oil bath was heated to 115° C. and kept under reflux for 1 hour to dehydrate the solvent and moisture in the apparatus by reacting with magnesium, and then cooled with ice water. 28.0 g (20 mL, 0.21 mol) of TCS was charged into a 50 mL supply tank, and when the internal temperature dropped to 5° C., 3 mL of TCS was charged into a 300 mL four-necked flask. While maintaining 10° C. or lower, DMA was supplied from the gas phase portion of the flask at a rate of 16 mL per minute for 1 hour.

[0091]

[0092] The oil bath was set at 90°C, and the temperature of the reaction solution was heated to above 80°C. During the heating, the reaction between the hydrochloride salt of DMA and magnesium occurred, but a significant rapid rise in temperature was not observed. When the internal temperature exceeded 80° C., TCS was adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com