Horizontal roof photovoltaic power station or heat collector mounting structure

A technology for installing structures and photovoltaic power stations, applied in the field of solar energy, can solve problems such as increasing construction costs, increasing heavy procedures, and damaging roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

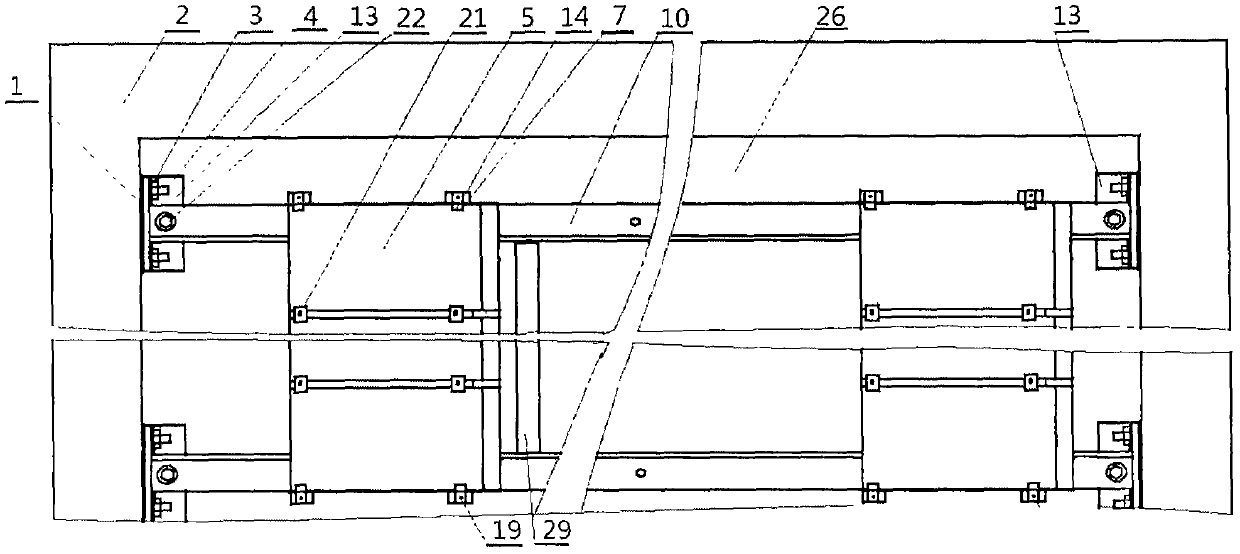

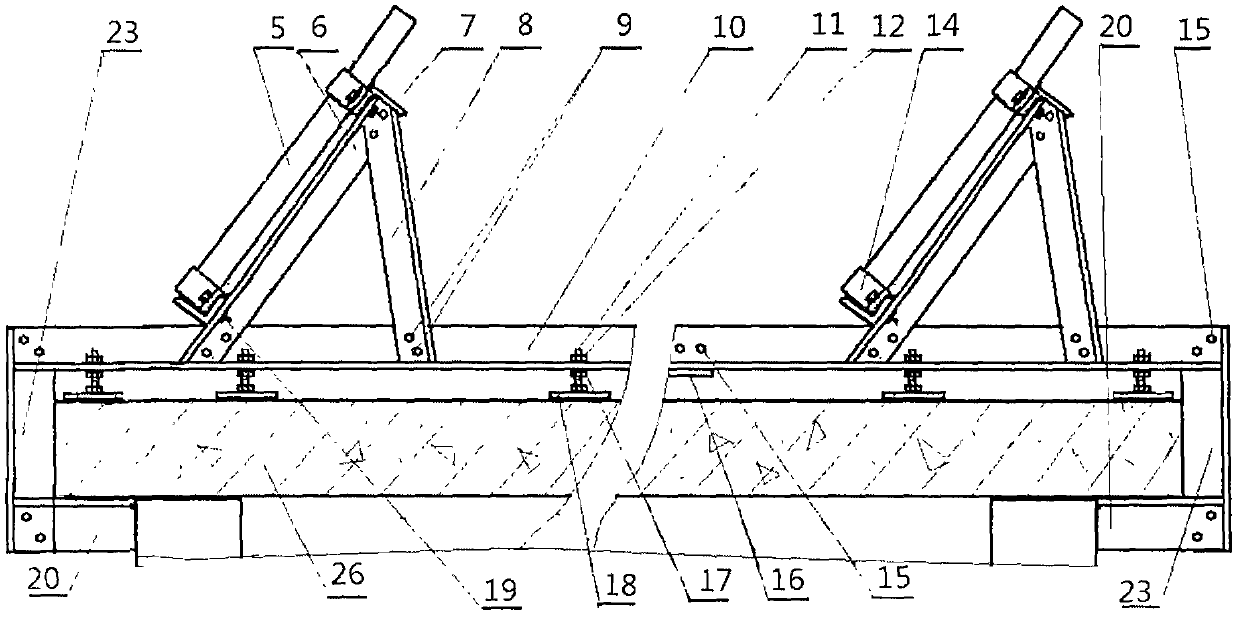

[0014] Photovoltaic panels (5) heat collectors are custom-made by professional enterprises according to given installation dimensions.

[0015] Steel structure parts such as bottom bracket (10), front support rod (6) and rear support rod (8), adjustment foot (18), lower cross bar (20), cross bar (7) are provided by a professional steel structure manufacturer Manufactured to order.

[0016] All bolts, nuts and washers are standard parts.

[0017] Transport all the above-mentioned components and other required devices, such as inverters, meters, wires, water pipes, etc. to the installation site, and install them step by step by professionals according to the design and installation drawings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com