Steel frame based on mechanical full-face excavation of tunnel, and construction method thereof

A full-section, steel frame technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of long single-process time, high precision requirements, and low construction efficiency, so as to reduce the number of construction workers and ensure the steel frame The effect of low support strength and low positioning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

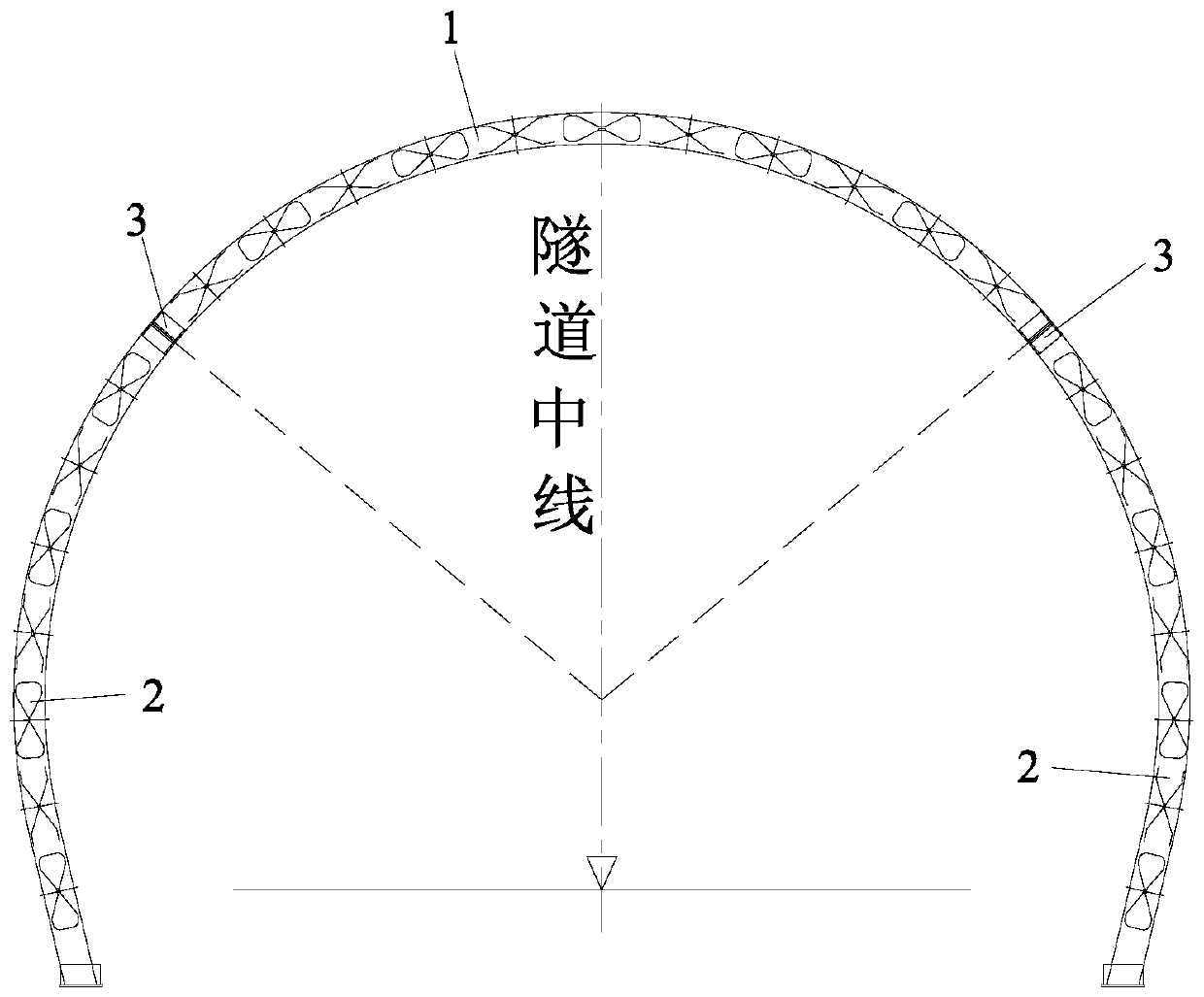

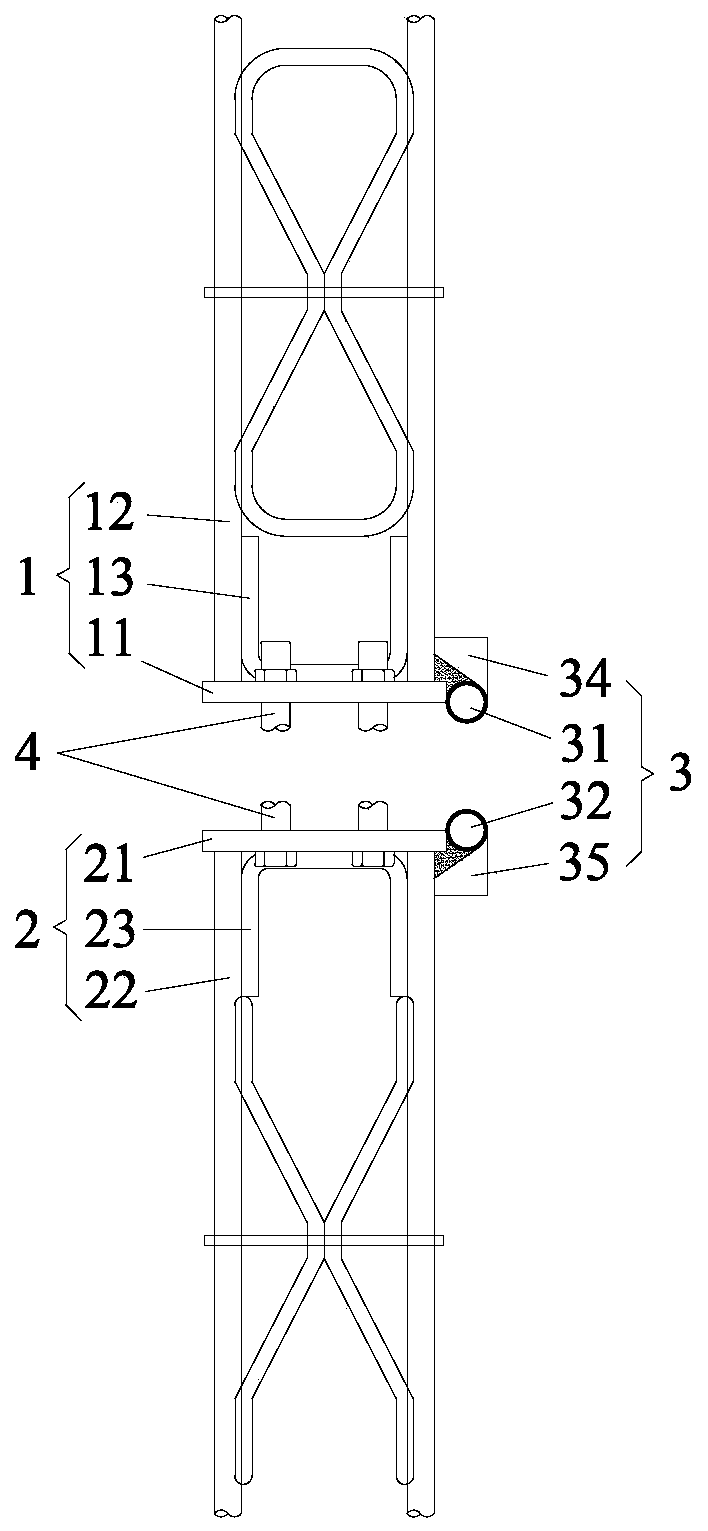

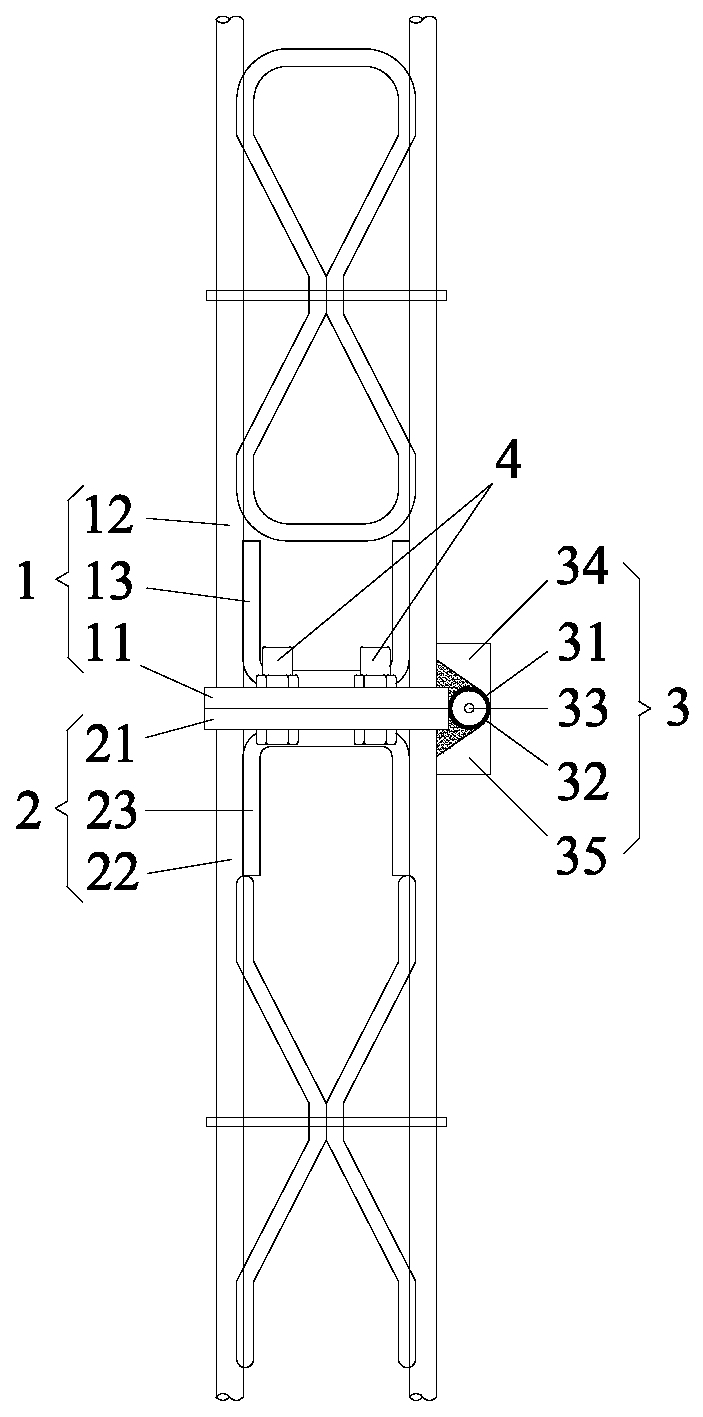

[0100] Such as Figure 1-8 As shown, a steel frame based on tunnel mechanized full-section excavation according to the present invention includes an arch grid steel frame unit 1 and side grid steel frame units 2 located at both ends thereof, as well as hinged parts 3 and locking Part 4, the arch grid steel frame unit 1 and the side grid steel frame unit 2 are prefabricated into an integral structure, and the length of the arch grid steel frame unit 1 is equal to that of the side grid The length of steel frame unit 2;

[0101] Such as Figure 2-4 As shown, the end of the arch grid steel frame unit 1 is provided with a first connecting steel plate 11, such as Figure 5 As shown, the first connecting steel plate 11 is welded with four first grid main ribs 12, and a first U-shaped rib 13 is welded between two adjacent first grid main ribs 12, each of the first The bottom of the U-shaped rib 13 is welded to the first connecting steel plate 11, specifically, the thickness of the ...

Embodiment 2

[0107] Such as Figure 9-16 As shown, a steel frame based on tunnel mechanized full-section excavation according to the present invention includes an arch section steel frame unit 5 and side section steel frame units 6 located at both ends thereof, as well as hinge parts 3 and locking parts 4 , the arch section steel frame unit 5 and the side section steel frame unit 6 are prefabricated into an integral structure, the length of the arch section steel frame unit 5 is equal to the side section steel frame unit 6;

[0108] Such as Figure 10-12 As shown, the end of the arch section steel frame unit 5 is provided with a third connecting steel plate 51, and the third connecting steel plate 51 is welded with a first section steel 52, and the two sides in the length direction of the first section steel 52 are respectively welded with a second A stiffener 53, the bottom of each first stiffener 53 is welded to the third connecting steel plate 51, the first stiffening rib 53 is an angl...

Embodiment 3

[0114] Such as Figure 17-19 As shown, a kind of steel frame construction method based on tunnel mechanized full-section excavation according to the present invention comprises the following steps:

[0115] A, the factory prefabricated arch steel frame unit 7 and the side steel frame units 8 at its two ends, wherein, the arch steel frame unit 7 adopts the arch grid steel frame unit 1 as described in embodiment 1, the The side steel frame unit 8 adopts the side grid steel frame unit 2 as described in Embodiment 1;

[0116] The inner side of the arch at the end of the arch steel frame unit 7 is provided with a hinged part 3, and the hinged part 3 is connected to one end of the side steel frame unit 8, and the side steel frame unit 8 can be opposite to the arch. The steel frame unit 7 rotates 0° to 150° towards the inner side of the arch, wherein at 0°, the ends of the arch steel frame unit 7 and the side steel frame unit 8 are aligned and abutted, and the arch steel frame unit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com