Closed steel bar framework of thick-roof arch structure and optimization method

An arched structure and steel frame technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of unfavorable pouring of concrete and binding of stirrups, and small density, so as to facilitate the construction of steel binding and increase the Bearing performance and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

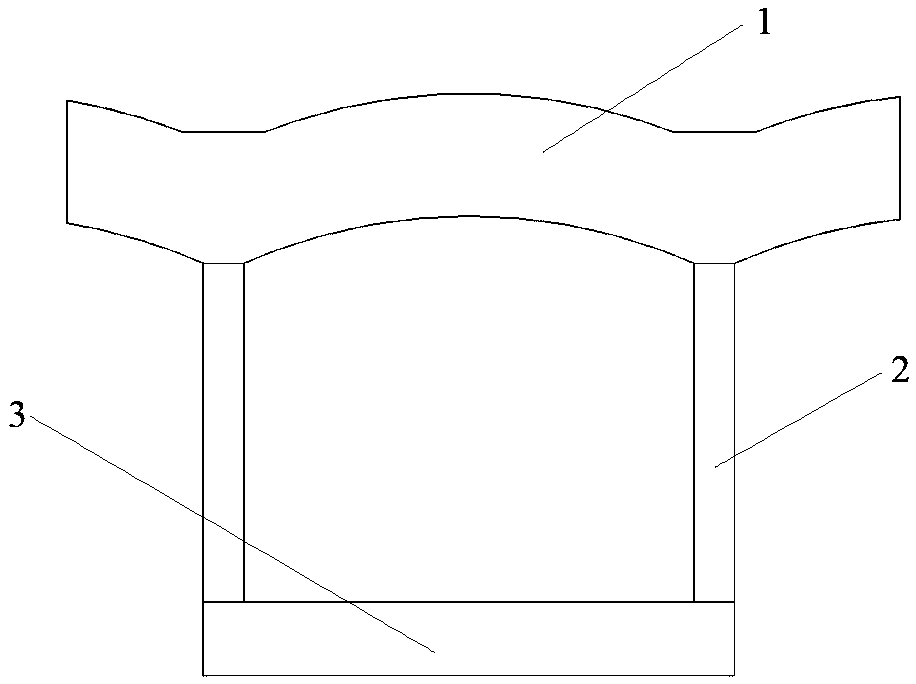

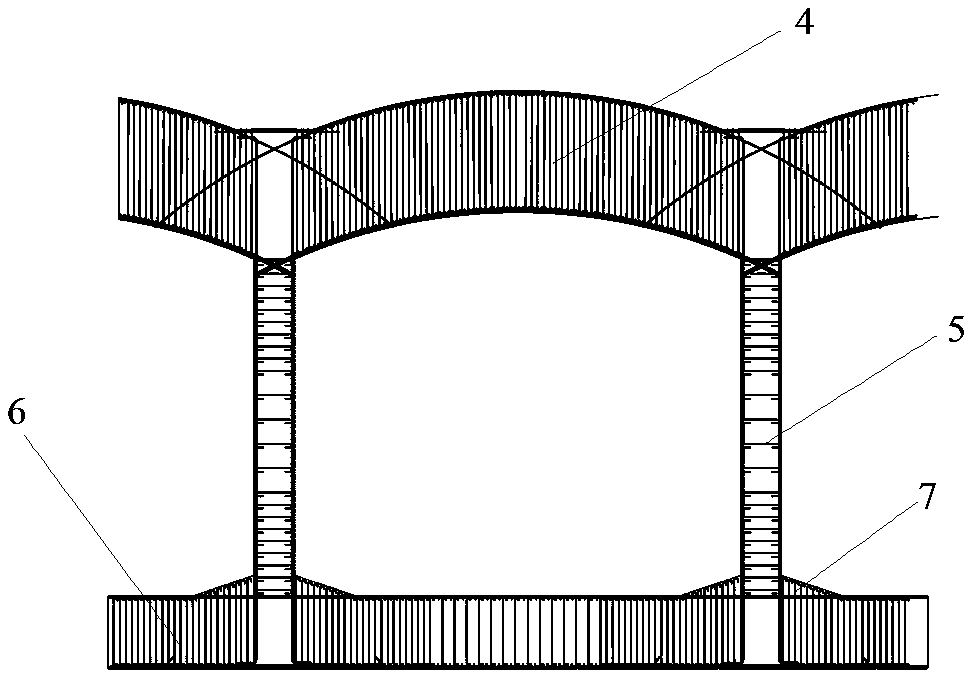

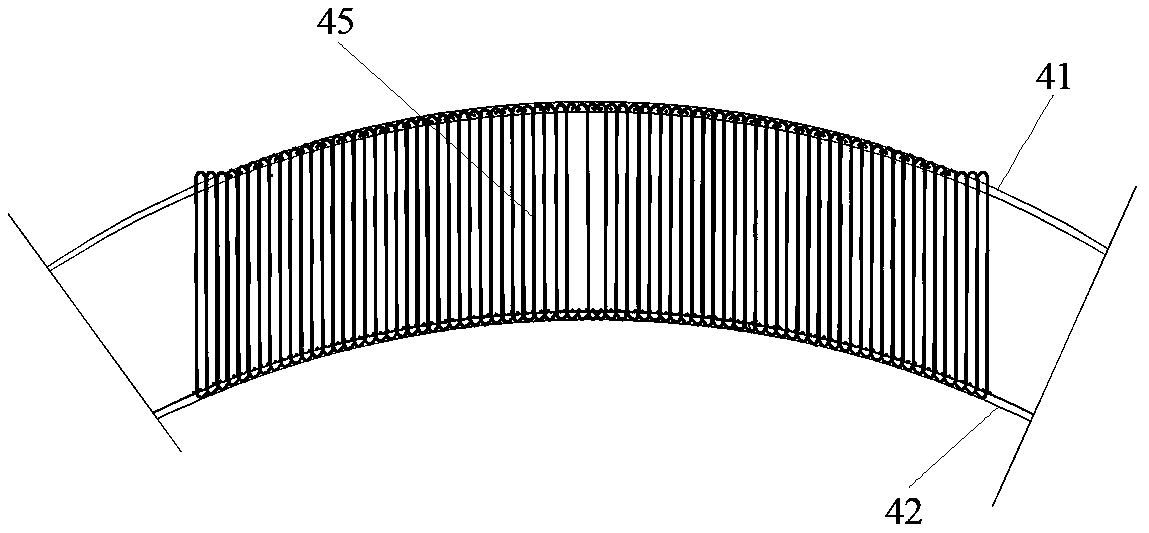

[0051] Such as figure 1 As shown, taking the arched structure of the thick roof as an example, it is made of reinforced concrete, including the roof 1, the partition wall 2 connected to the two ends of the roof 1, and the bottom plate 3 connected to the bottom ends of the two partition walls 2, wherein the thickness of the roof 1 is 2.0m-3.0m; if figure 2As shown, the closed reinforcement frame of the arched structure includes the roof reinforcement frame 4 located on the roof 1 of the arched structure, the partition wall reinforcement frame 5 connected to the two ends of the roof reinforcement frame 4, and the floor reinforcement frame connected to the bottom of the two partition wall reinforcement frames 5 Frame 6; the roof reinforcement frame 4 is arranged in layers, and each layer includes circumferential ribs along the arched structure and radial ribs along the long direction of the arched structure, and the circumferential ribs and radial ribs are staggered to form each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com