High-efficiency anti-depressurization rotating impact screw drilling tool

A screw drilling tool and anti-separation technology, which is applied in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc. phenomenon, increase the ROP, and eliminate the effect of stick-slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

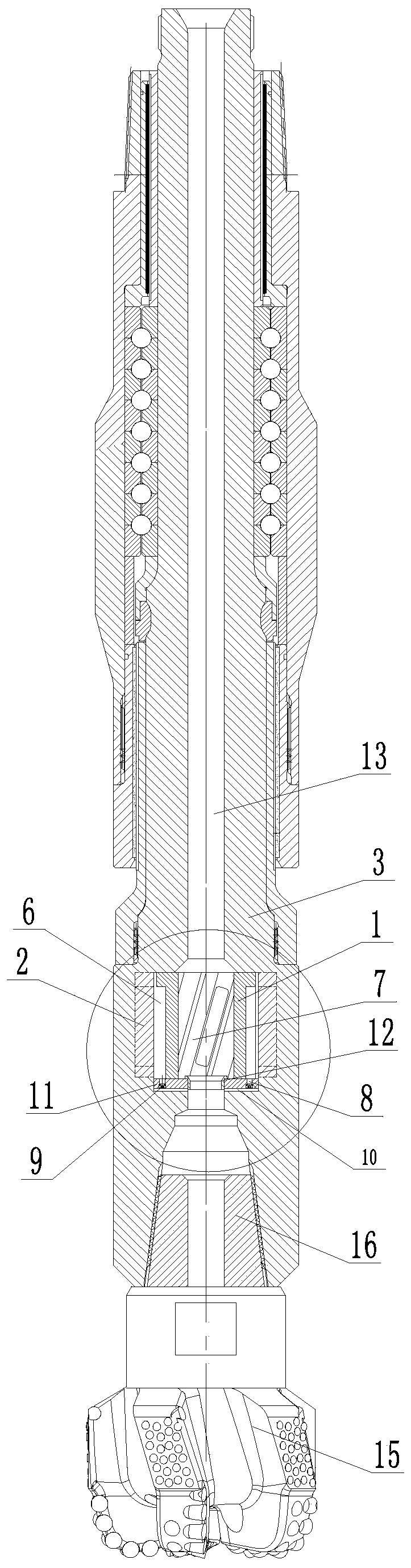

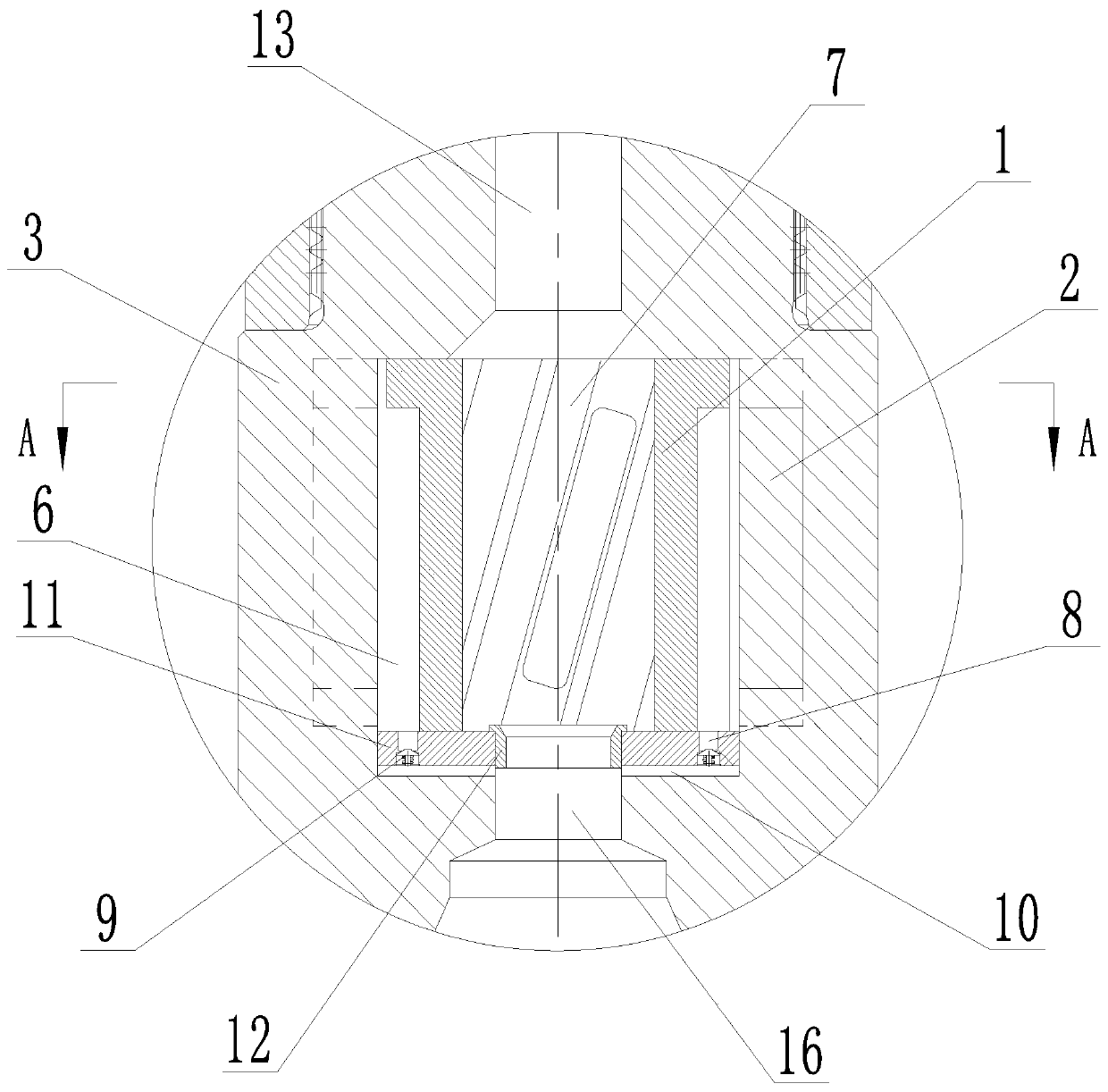

[0013] refer to Figure 1-Figure 3 , the high-efficiency anti-depressurization rotary impact screw drilling tool described in this embodiment includes a drill pipe with a transmission shaft 3 inside and a drill bit 15, and the tail end of the drill bit 15 is assembled on the bottom end of the transmission shaft 3 through the drill bit connector 16; The transmission shaft 3 is provided with an axial transmission shaft inner hole 13 .

[0014] The lower end of the transmission shaft 3 is equipped with a rotary hammering device, and the rotary hammering device is located between the bottom port of the transmission shaft inner hole 13 and the tail port of the drill bit connecting body 16 .

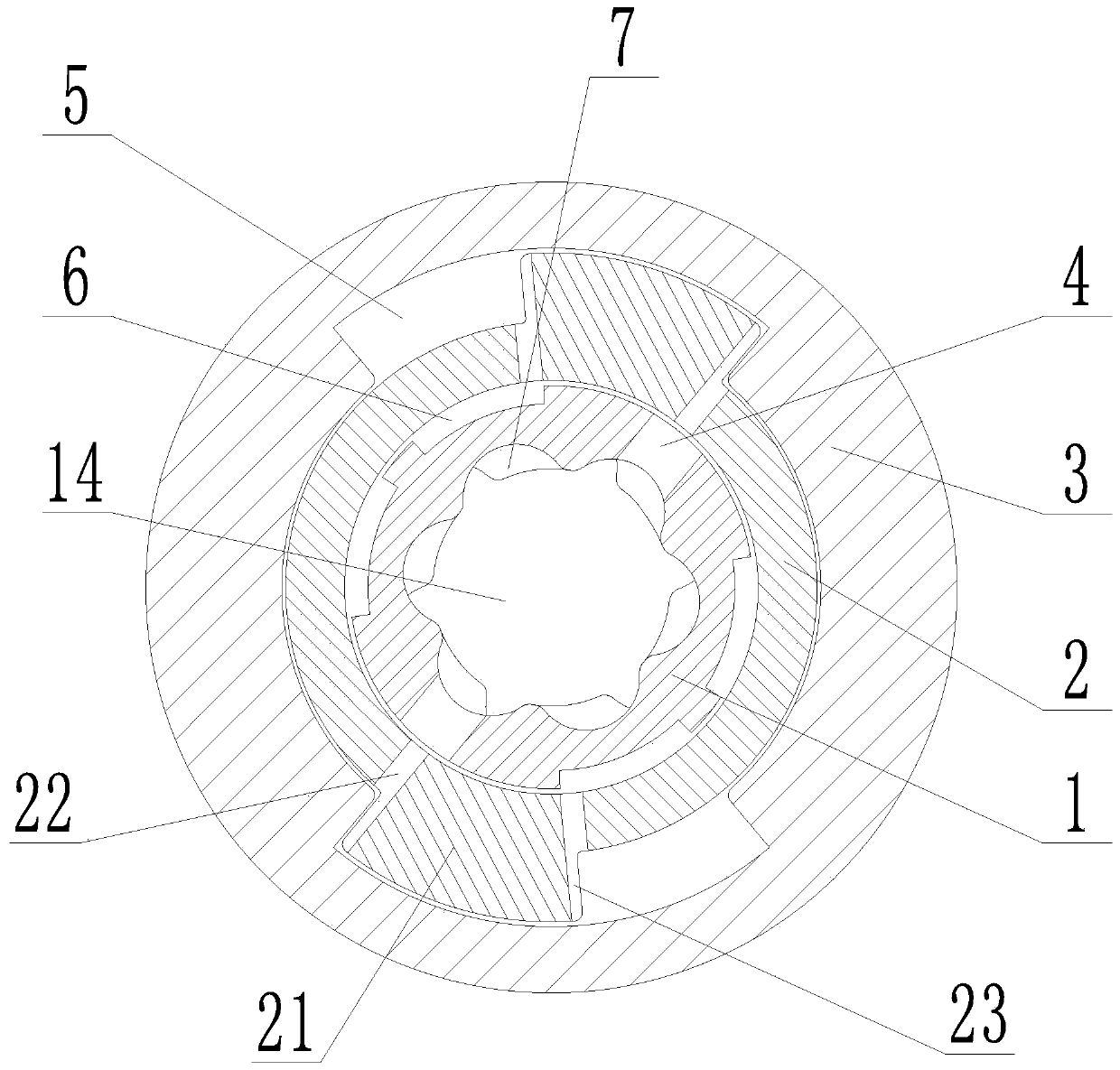

[0015] The rotary hammering device includes a hammer body and a rotary sleeve body. The hammer body includes a hollow and cylindrical hammer sleeve 2 and two impact hammers 21 axially arranged on the outer wall of the hammer sleeve 2. The two impact hammers 21 Symmetrical to each other, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com