Bacillus megaterium living bacteria agent, liquid fermentation process and application thereof

A technology of Bacillus megaterium and liquid fermentation, applied in application, bacteria, food processing, etc., to achieve green research and development, meet demand, and overcome the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Identification of Bacillus megaterium BM1259 of the present invention

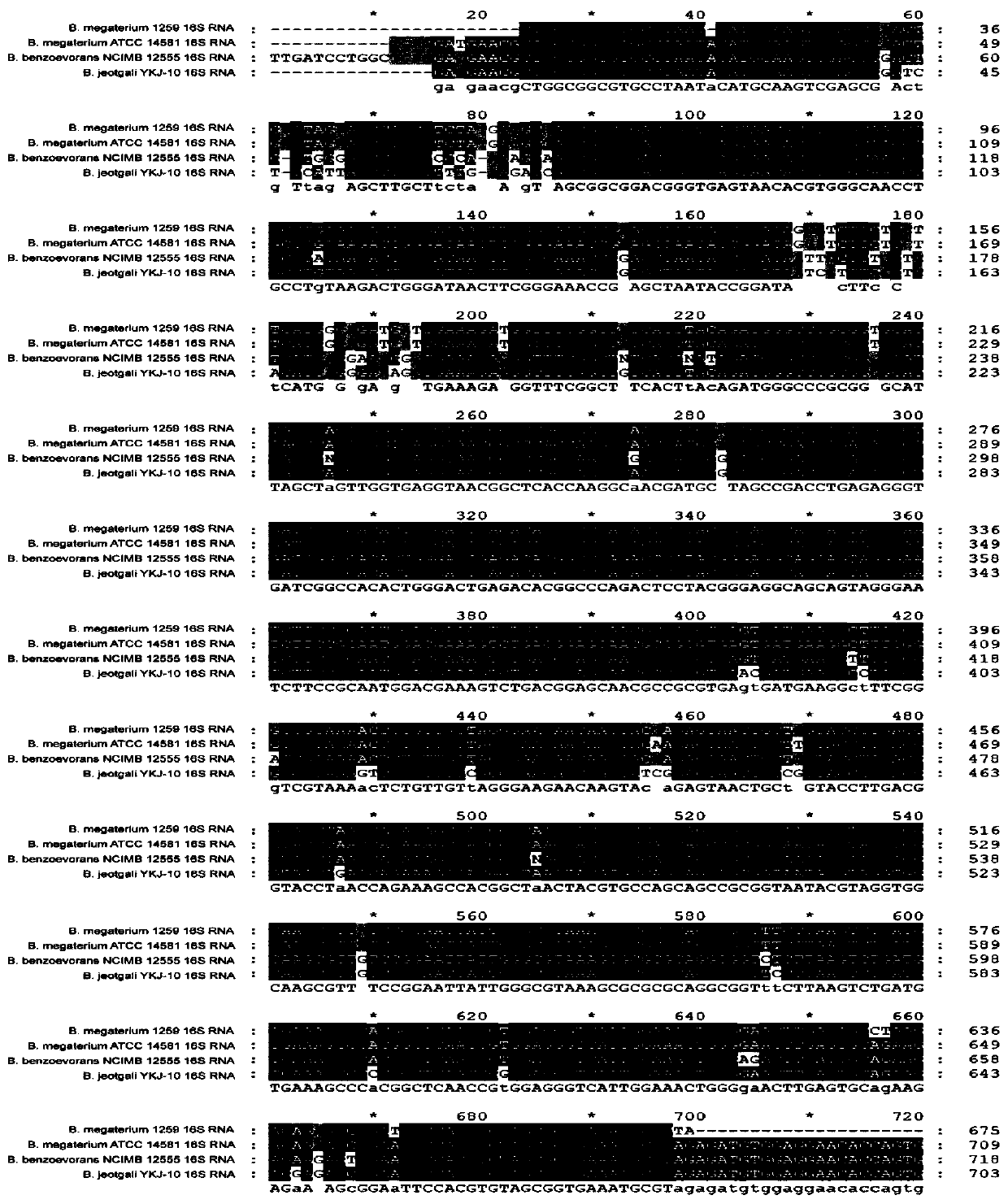

[0030] Primers were designed according to the DNA sequence of the obtained strain BM1259, and its 16S rRNA was amplified and sequenced. The obtained sequence was compared with the 16S rRNA of other species in the NCBI database, and the results showed that BM1259 had a high homology with B. megaterium ATCC14581, and BM1259 was identified as a species of B. megaterium ( figure 1 ).

[0031] Embodiment 2 Shake flask test: the impact of Bacillus megaterium BM1259 on the degradation of ammonia nitrogen

[0032] Take the Bacillus megaterium with the preservation number: GMCC No: 1259, inoculate it in a Erlenmeyer flask equipped with a cell rejuvenation liquid medium (beef extract peptone), and culture it at 30-34° C. and 180 rpm for 18-20 hours. According to the inoculum amount of 10%, the activated bacterial solution was inserted into the ammonia nitrogen medium with different initial conc...

Embodiment 3

[0033]Example 3 Animal Experiment: Effects of Adding Bacillus megaterium BM1259 in Diets on Production Performance, Rumen Fermentation and Biochemical Indexes of Lactating Dairy Cows

[0034] 24 Chinese Holstein dairy cows with similar milk production, lactating age and parity were selected and randomly divided into 4 groups with 6 cows in each group. d (control group), 5g / d, 10g / d and 15g / d, to study the effect of Bacillus megaterium BM1259 on the production performance, rumen fermentation and biochemical indicators of lactating dairy cows. The result is as follows:

[0035] (1) The standard milk yield, milk protein rate and milk fat rate of the experimental group supplemented with 10-15g Bacillus megaterium BM1259 were significantly higher than those of the control group. The apparent digestibility of neutral detergent fiber nutrients 15g / d group was significantly higher than that of the control group (Table 1), wherein the control group: the level of Bacillus megaterium BM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com