Hemihydrate phosphogypsum-based filling material and preparation method and application thereof

A technology of hemihydrate phosphogypsum and filling material, which is applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve the problems of inability to activate phosphogypsum alkali, low content of alkaline components in low-calcium fly ash, etc., and achieve low cost , good liquidity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

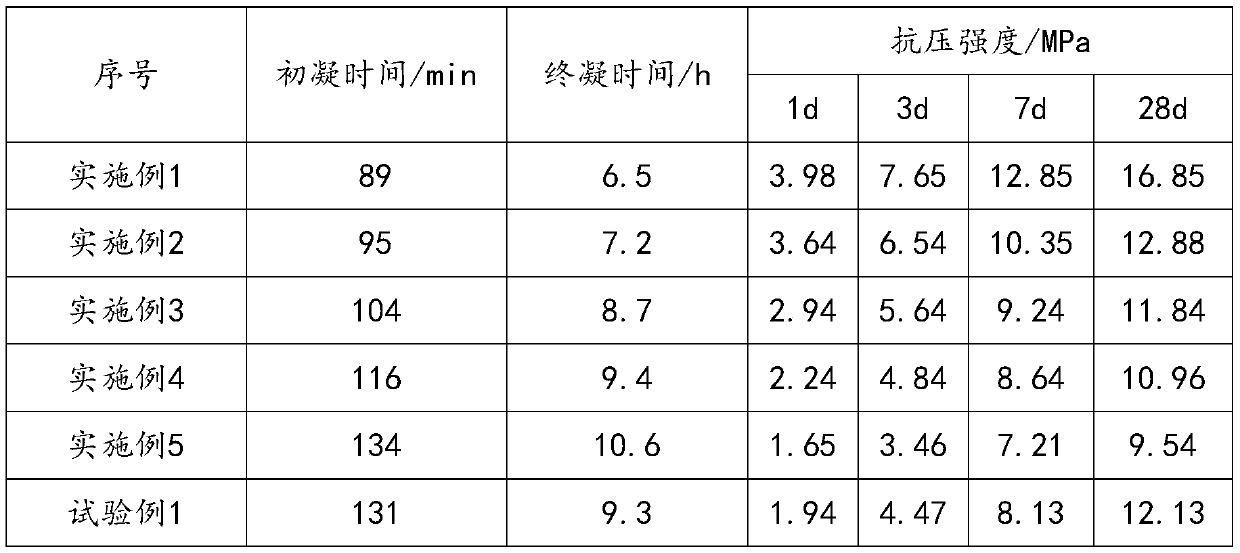

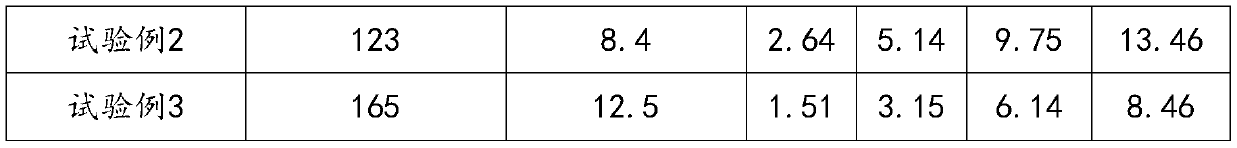

Examples

Embodiment 1

[0044] A preparation method of hemihydrate phosphogypsum-based filling material, comprising the steps of:

[0045] (1) Get the following raw materials in parts by weight: 100 parts of phosphogypsum hemihydrate, 20 parts of auxiliary gel material (the component distribution ratio is: 70 parts of high calcium fly ash, 20 parts of wet discharge fly ash, 10 parts of cement) , 5 parts of composite coagulant (the component distribution ratio is 40 parts of sodium metasilicate, 60 parts of sodium hydroxide), 5 parts of adsorption dispersant (the component distribution ratio is: 40 parts of calcium-based bentonite, 60 parts of sodium-based bentonite), 4 parts of hydroxypropyl methylcellulose ether, 1 part of composite water reducer (component distribution ratio: 40 parts of polycarboxylate superplasticizer, 60 parts of Nai series water reducer);

[0046] (2) mixing and stirring the raw materials prepared in step (1) and water at a mass ratio of 1:0.8 to obtain a hemihydrate phosphogyp...

Embodiment 2

[0049] A preparation method of hemihydrate phosphogypsum-based filling material, comprising the steps of:

[0050] (1) Get the following raw materials in parts by weight: 150 parts of phosphogypsum hemihydrate, 15 parts of auxiliary gel material (the component distribution ratio is: 80 parts of high calcium fly ash, 15 parts of wet row fly ash, 5 parts of cement) , 2 parts of composite coagulant (the component ratio is 30 parts of sodium metasilicate, 70 parts of sodium hydroxide), 2 parts of adsorption dispersant (the component ratio is: 60 parts of calcium-based bentonite, 40 parts of sodium-based bentonite), 2 parts of hydroxypropyl methylcellulose ether, 1.5 parts of composite water reducer (component ratio: 60 parts of polycarboxylate high-efficiency water reducer, 40 parts of Nai series water reducer);

[0051] (2) mixing and stirring the raw materials prepared in step (1) and water at a mass ratio of 1:0.9 to obtain a hemihydrate phosphogypsum-based filling material;

...

Embodiment 3

[0054] A preparation method of hemihydrate phosphogypsum-based filling material, comprising the steps of:

[0055] (1) The following raw materials are taken in parts by weight: 50 parts of phosphogypsum hemihydrate, 15 parts of auxiliary gel material (the component distribution ratio is: 60 parts of high-calcium fly ash, 30 parts of wet-discharge fly ash, 10 parts of cement) , 3 parts of composite coagulant (component ratio: 35 parts of sodium metasilicate, 65 parts of sodium hydroxide), 3 parts of adsorption dispersant (component ratio: 45 parts of calcium-based bentonite, 55 parts of sodium-based bentonite), 3 parts of hydroxypropyl methylcellulose ether, 0.5 parts of composite water reducer (component ratio: 50 parts of polycarboxylate superplasticizer, 50 parts of Nai series water reducer);

[0056] (2) mixing and stirring the raw materials prepared in step (1) and water at a mass ratio of 1:1.0 to obtain a hemihydrate phosphogypsum-based filling material;

[0057] (3) Tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com