Mixing device for dye production

A mixing device and dye technology, applied in mixers, sampling devices, measuring devices, etc., can solve the problems of inconvenient sampling and inspection of mixing degree, no dye dust barrier, etc., and achieve the effect of improving efficiency and increasing sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

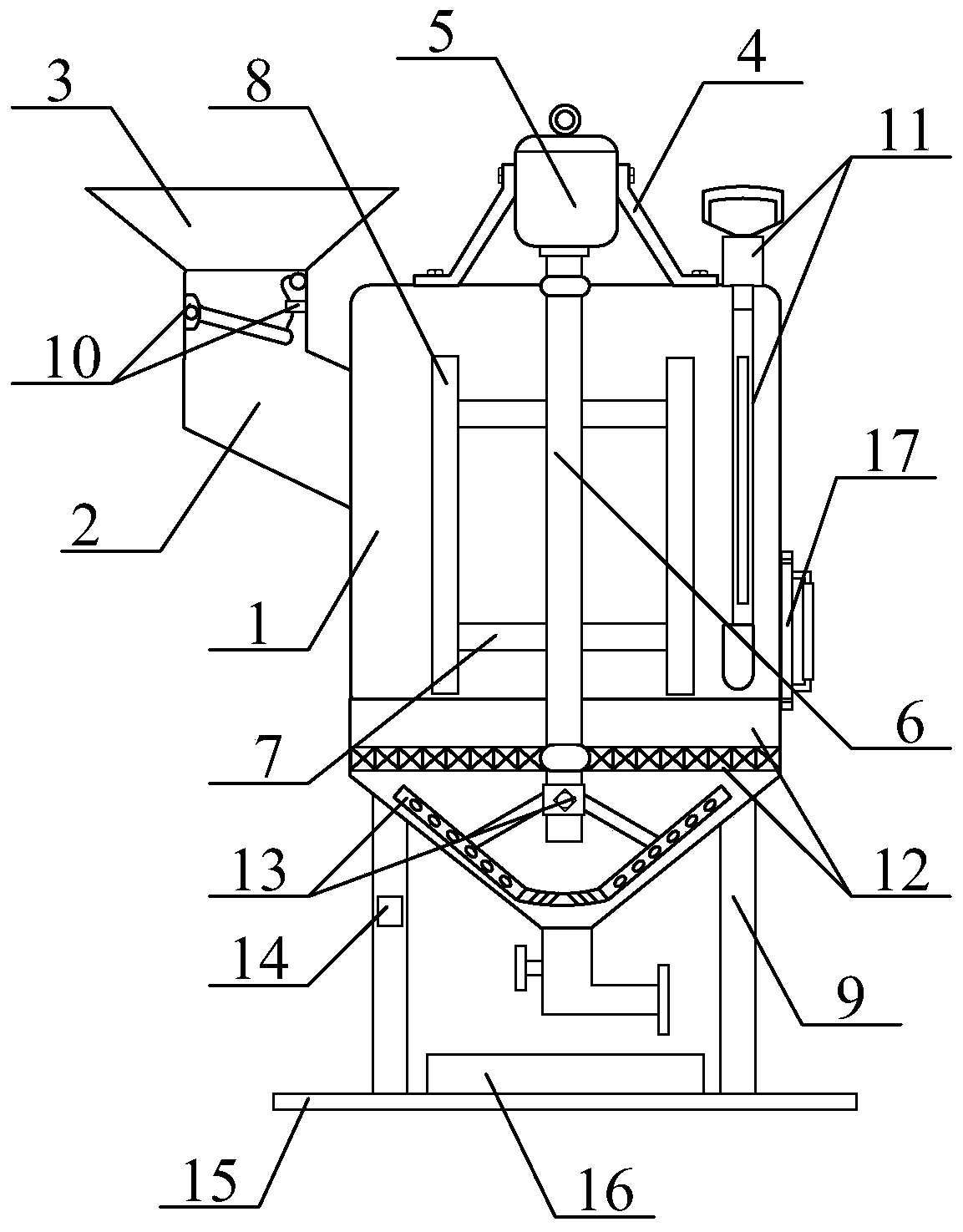

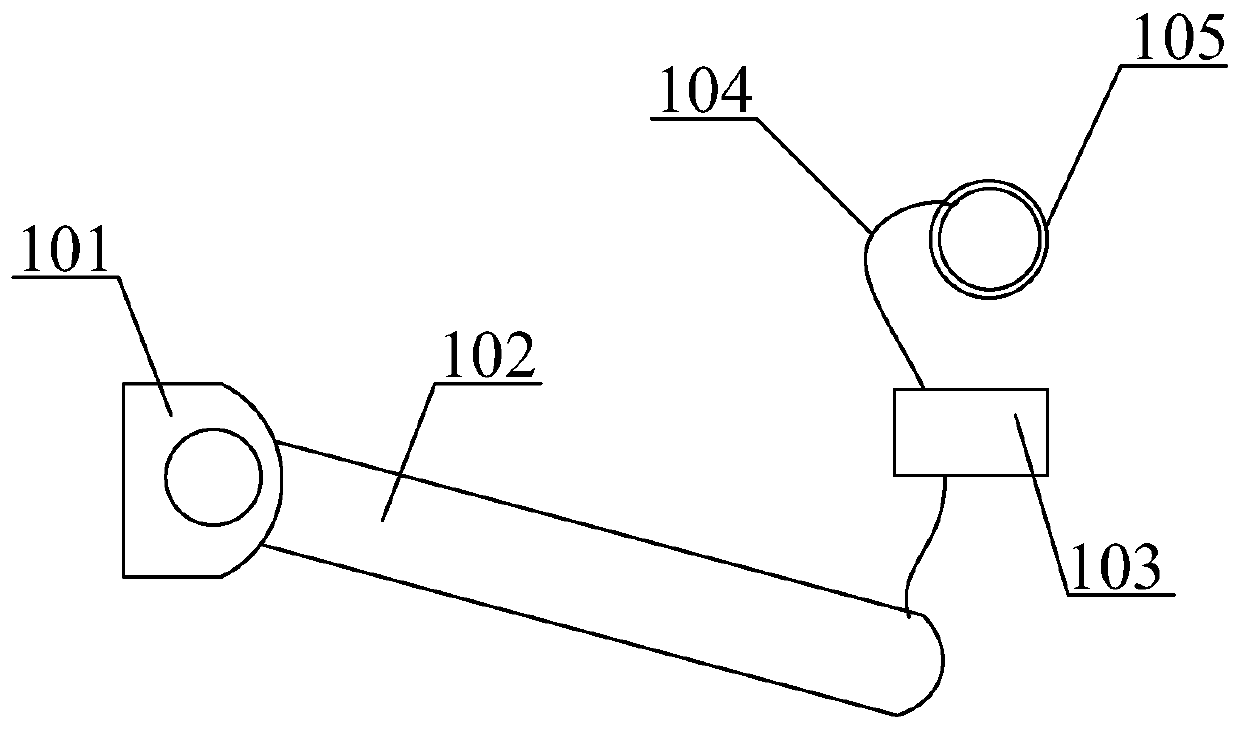

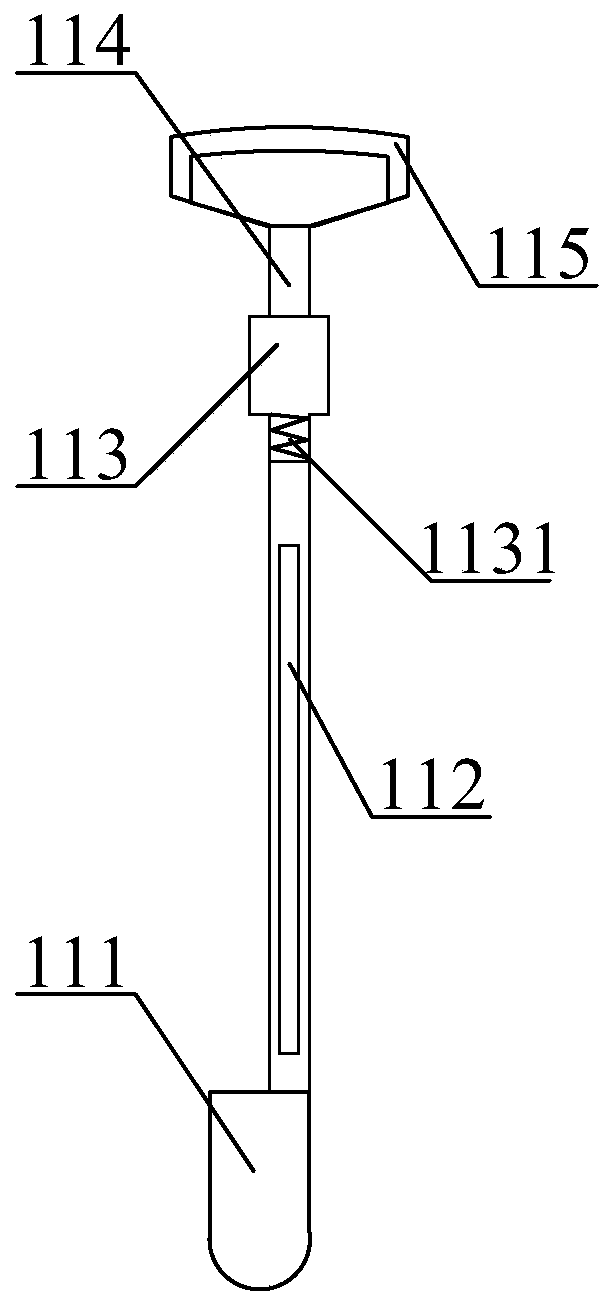

[0050] see Figure 1-Figure 5 As shown, the present invention provides a mixing device for dye production, comprising a mixing tank 1, a feeding conduit 2, a hopper 3, a motor support 4, a mixing motor 5, a stirring shaft 6, a horizontal stirring rod 7, a vertical stirring rod 8. Support column 9. Self-resetting anti-dust sealing plate structure 10. Sampling detection rod structure 11. Filterable layered mesh structure 12. Bottom mixing rod structure that can guide flow 13. Mixing control switch 14. Support base Plate 15 and leakage material receiving pan 16.

[0051] The feeding conduit 2 is welded on the upper left side of the stirring mixing barrel 1 and communicated with the inside of the stirring mixing barrel 1; the feeding hopper 3 is welded on the upper surface of the feeding conduit 2; one end of the motor bracket 4 is respectively bolted to the mixing and stirring motor 5, the upper position on the left and right sides, the other end bolts are connected to the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com